1. Introduction

In today’s electronics manufacturing world, the acronyms SMT, SMD, and EMS are frequently used — but what do they mean, and how do they differ? This article explains each term clearly, compares them, and shows how they interrelate in the manufacturing value chain.

2. What is SMT?

2.1 Definition of SMT

Surface Mount Technology (SMT) refers to the process of mounting electronic components directly onto the surface of a printed circuit board (PCB).

2.2 Key Features and Advantages

- Faster, highly automated assembly.

- Higher component density and smaller device size.

- Supports modern compact electronics manufacturing.

2.3 Typical Process Steps

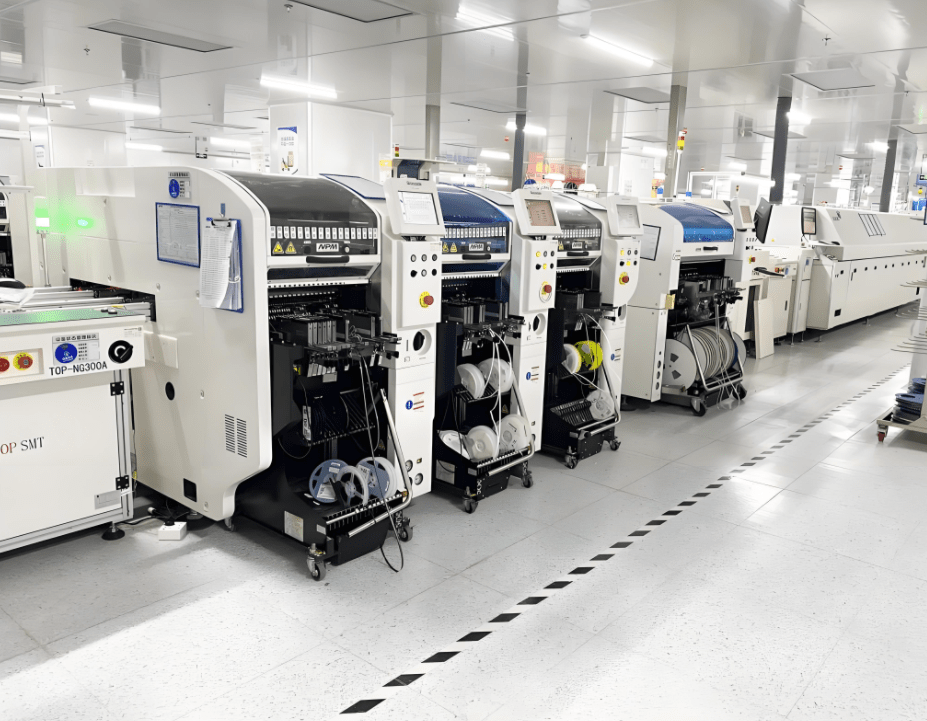

Typical steps: solder paste printing → pick-and-place → reflow soldering → inspection and testing.

3. What is SMD?

3.1 Definition of SMD

Surface Mount Device (SMD) refers to the actual components that are mounted via SMT.

3.2 Features of SMDs

SMDs are small, lightweight components designed for high-density PCB assembly; they use flat contacts or solder balls rather than long leads.

3.3 Why SMDs Matter

SMDs enable miniaturization, lower cost and improved performance.

4. What is EMS?

4.1 Definition of EMS

Electronics Manufacturing Services (EMS) are companies that design, manufacture, test, distribute and provide services for electronic components and assemblies for OEMs.

4.2 Role of EMS in the Value Chain

EMS providers often handle turnkey manufacturing—from PCB assembly using SMT/SMD to product testing, final assembly and logistics.

5. Key Differences Between SMT, SMD & EMS

5.1 SMT vs SMD

SMT = the assembly process. SMD = the component itself.

5.2 EMS vs SMT/SMD

EMS covers full-service manufacturing (may use SMT processes and SMD parts) and adds services like supply-chain, testing and logistics.

5.3 Summary Table

| Term | Meaning | Main Focus |

|---|---|---|

| SMT | Surface Mount Technology | Assembly process |

| SMD | Surface Mount Device | Component itself |

| EMS | Electronics Manufacturing Services | Turnkey manufacturing service |

6. How They Fit Together

- Designers choose SMDs (components).

- EMS providers use SMT processes to mount SMDs onto PCBs.

- EMS may also do testing, assembly and logistics.

7. Conclusion

SMT is the process, SMD is the component, EMS is the service provider — understanding these relationships clarifies roles in electronics manufacturing.

8. Related Reading

Below are example internal links — REPLACE THESE with your real site URLs in the `internalLinks` mapping (see script at bottom):

为 Troubleshooting a Tray Loader: Synchronization Issues | SMT Pack Lab – SMTPack LAB – Automated Taping & Tray Packing for Smd Components 发表评论 取消回复