In the world of electronics manufacturing, the terms SMD and SMT often come up, but many newcomers—and even some experienced professionals—confuse them. Understanding the distinction between the two is essential if you want to navigate the electronics production chain effectively, especially if you work with taping machines, tray packing machines, or other automated SMT equipment.

Related reading: What Is SMT? A Complete Overview of Surface Mount Technology | What Is SMD? Understanding Surface-Mounted Devices

1. What Is SMD?

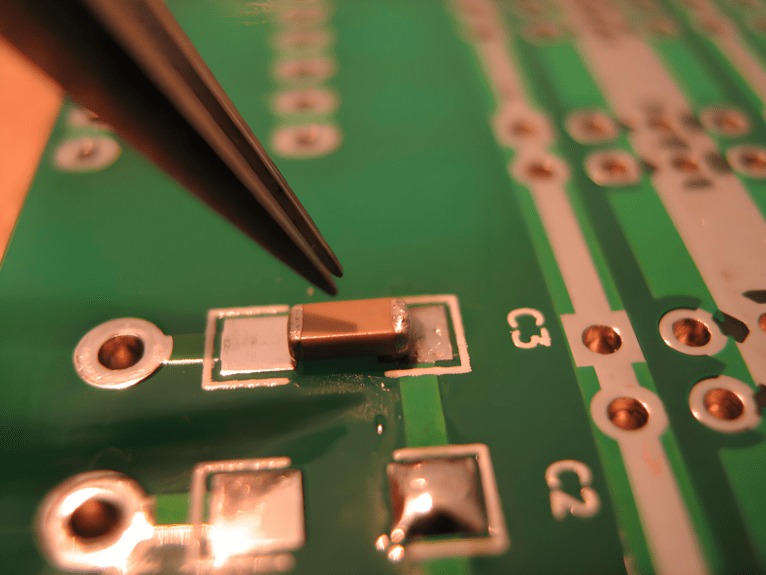

SMD stands for Surface-Mounted Device. These are the actual electronic components designed to be placed directly onto the surface of a printed circuit board (PCB). Common examples include:

- Resistors

- Capacitors

- Integrated Circuits (ICs)

- Diodes and LEDs

Unlike traditional through-hole components, SMDs are compact, lightweight, and suitable for high-density PCB designs. They are usually packaged in tapes or trays, ready for automated placement.

Key point: SMD refers to the component itself, not the process.

2. What Is SMT?

SMT, or Surface Mount Technology, is the method used to attach SMDs to PCBs. It encompasses the entire process:

- Solder Paste Application: Applying solder paste to PCB pads.

- Component Placement: Using pick-and-place machines to position SMDs accurately.

- Reflow Soldering: Heating the assembly so the solder melts and bonds components.

- Inspection & Testing: Ensuring proper placement and electrical performance.

If you want a deeper dive into SMT processes and equipment, check out: What Is SMT? A Complete Overview of Surface Mount Technology.

Key point: SMT is the process, while SMD is the component.

3. How SMD and SMT Work Together

Think of it this way:

- SMD = the ingredient

- SMT = the recipe

Without SMDs, SMT has nothing to place. Without SMT, SMDs cannot become part of functional PCBs efficiently. For electronics manufacturers, understanding both is crucial for designing workflows, selecting machines, and optimizing production efficiency.

4. Practical Implications for SMT Equipment Providers

For companies like SMT PACK LAB, which specialize in taping machines, tray packing machines, and smart inspection systems, distinguishing SMD from SMT helps you:

- Identify the right packaging for components

- Optimize pick-and-place and feeder setups

- Improve production yield and reduce defects

Learn more about SMD packaging and types: What Is SMD? Understanding Surface-Mounted Devices

5. Summary Table: SMD vs SMT

Feature SMD SMT Meaning Surface-Mounted Device Surface Mount Technology Type Component Process/Method Examples Resistor, Capacitor, IC Placement, Reflow, Inspection Purpose Forms part of PCB Attaches SMDs to PCB Relevance to SMT Equipment Machines handle SMDs for automated placement Machines execute SMT steps

6. Final Thoughts

Understanding the distinction between SMD and SMT is not just academic—it impacts equipment choice, production planning, and efficiency. For electronics manufacturing professionals, mastering these concepts is the first step toward higher-quality PCB assembly.

Don’t forget to explore:

为 How to Optimize Taping Efficiency in Low-Volume PCB Production – SMT PACK LAB – Automated Taping & Tray Packing for SMD Components 发表评论 取消回复