Core Introduction

In the era of miniaturization and traceability-driven electronics manufacturing, a clear, permanent, and indelible mark serves as a unique identity for each component throughout its lifecycle—from production, testing, to end-use and recycling.

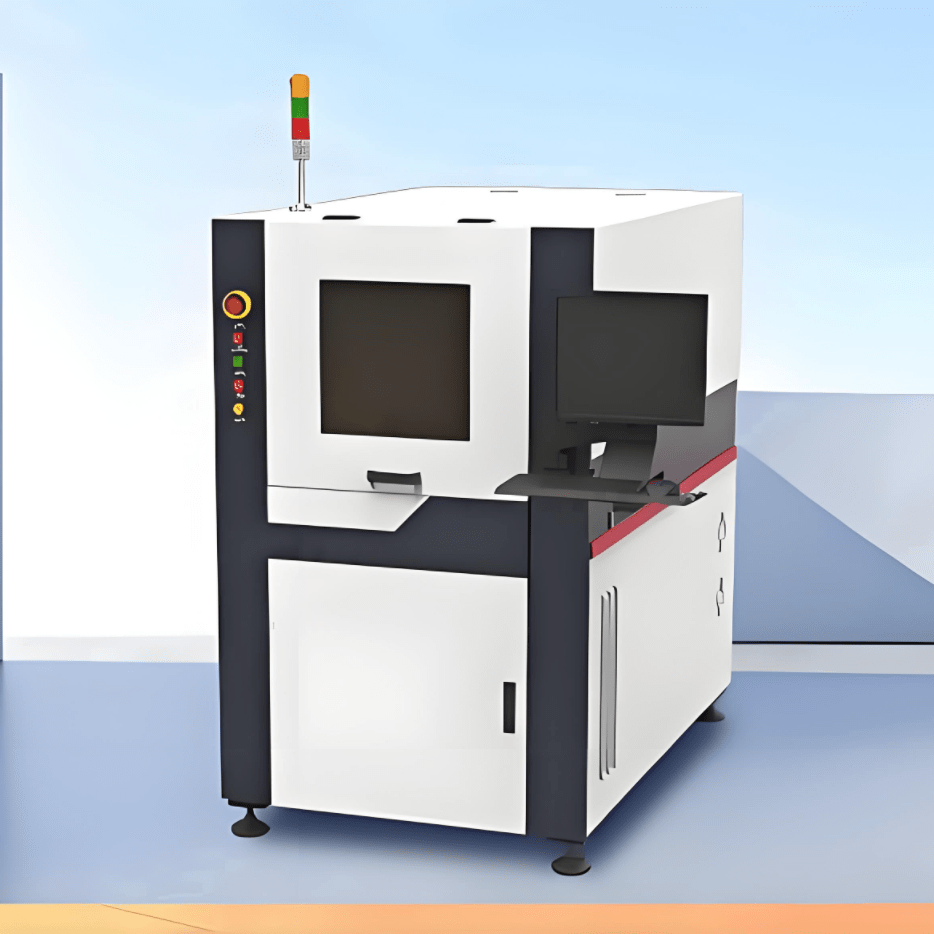

The SMTPack LAB AMT Laser Marking System is meticulously designed for high-precision SMD component marking, embedding quality and smart connectivity within microns, enabling transparent and digitized smart manufacturing.

Chapter 1: Precision Challenges in SMD Component Marking

- Extreme precision and space constraints: Micro-components like 01005, 0201 require very small marking areas, posing challenges for traditional marking methods.

- Durability and reliability: Ink markings may fade; mechanical marking may cause micro-cracks. Permanent marks are critical in automotive, aerospace, or high-temperature environments.

- Speed and flexibility: High production line speeds demand high throughput and fast switching between varieties without consumables.

- Data integration and traceability: Marking devices need to be MES/ERP connected nodes, capable of marking variable data like serial numbers, QR codes, and production dates in real time.

The AMT system addresses these challenges with non-contact, consumable-free, and highly flexible marking.

Chapter 2: Core Advantages of AMT Series

2.1 Extreme Marking Precision

- High-quality fiber laser with micron-level focus for 1D/2D codes, characters, and graphics.

- High-precision motion platform with repeatability ±0.001mm.

2.2 Material Compatibility

- Plastics: ABS, PC, Epoxy

- Metals: Copper, Aluminum, Alloys, Gold/Silver surfaces

- Ceramics: Alumina, LTCC

- Coatings: Ink or painted surfaces

2.3 High Speed & Throughput

- High-speed vector scanning, UPH ≥ 3000 pcs

- Optional flying marking with precise sensors for continuous production line marking

2.4 Reliability & Stability

- Laser source lifespan >100,000 hours

- Integrated industrial design, dust-proof and robust

- Maintenance-free, consumable-free operation

2.5 Smart Integration

- MarkingPro™ software with graphical interface, database support, and MES/PLC connectivity

- Optional high-res CCD vision system for automatic positioning correction

Chapter 3: Applications

3.1 Chip & IC Marking

- Marks: model, batch, production date, unique serial number, logo, QR code

- Challenge: small marking area, diverse materials

- Solution: optimized laser power, frequency, and speed for high-contrast, non-damaging marking

3.2 Passive Component Marking

- Marks: value, tolerance, brand

- Challenge: ultra-small sizes (0201, 01005), heat sensitivity

- Solution: ultra-fine spot, cold processing ensures no performance degradation

3.3 Modules & Connectors

- Marks: model, PIN1, safety marks, data matrix

- Challenge: large marking area, speed and consistency

- Solution: high-speed galvanometer scanning, consistent quality

Chapter 4: Technical Specifications

4.1 Standard Parameters

| Item | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Laser Wavelength | 1064nm (other wavelengths optional) |

| Marking Area | 100 x 100 mm (optional larger area) |

| Marking Speed | ≤ 10000 mm/s |

| Line Width | 0.01 – 0.1 mm |

| Minimum Character Height | 0.2 mm |

| Repeatability | ±0.001 mm |

| Power | 220V / 50-60Hz / 1.5KW |

| Communication | Ethernet, RS232, I/O |

4.2 Optional Modules

- Laser power: 20W, 30W, 50W

- CCD vision system with pre-scan for precise alignment

- Automation interface with custom fixtures and robot communication

- Software modules: QR/data matrix verification, marking quality inspection

Chapter 5: Why Choose SMTPack LAB AMT Series?

- Deep industry understanding of SMD marking challenges

- Excellent cost-performance ratio

- Comprehensive support from pre-sale to post-sale

- Continuous innovation and R&D upgrades

Conclusion

In the era of IoT and smart manufacturing, a small mark is the key to a digital identity. The SMTPack LAB AMT Laser Marking System is your partner for building a traceable product lifecycle and moving towards Industry 4.0.Contact Us for Free Sample Marking