Hero Section

Beyond Programming: Where Every Bit is Verified, Every Chip has an Identity.

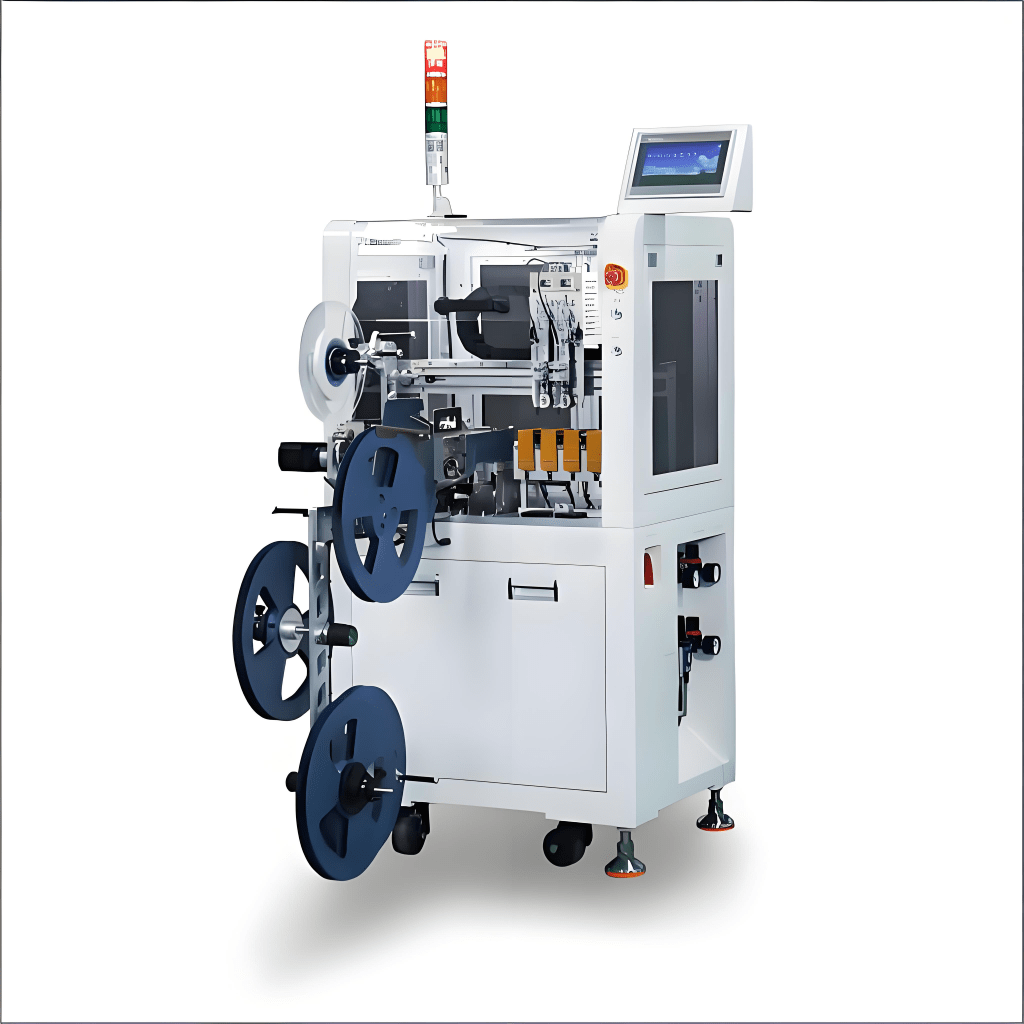

The Axiom-ICPP Smart Chip Programming Platform is more than a programming device—it is a strategic guardian of your data security, quality assurance, and smart manufacturing process. Engineered to meet the extreme requirements of global EMS manufacturers and distributors in automotive electronics, AI, Industry 4.0, and IoT.

- Extreme Throughput: Industry-leading parallel programming channels and intelligent scheduling, boosting capacity up to 300%.

- Military-Grade Data Security: End-to-end encryption and tamper-proof audit logs to protect firmware IP.

- Adaptive Intelligent Programming: AI algorithms optimize parameters in real time to maximize yield.

- Full Lifecycle Traceability: From wafer to product, building an immutable chip-level data gene chain.

- Global Compliance Engine: Embedded ISO 26262, ASPICE, IATF 16949 workflows for simplified certification.

Challenges of the Era and Our Solution

- Data Security “Black Box” Crisis: Firmware IP faces risks of leakage, tampering, and version errors; traditional tools lack closed-loop audit.

- Chip Complexity Yield Trap: Advanced chips are sensitive to voltage and timing; static parameters can cause latent defects and costly recalls.

- Production Bottleneck: Serial flashing slows down as chip capacity grows, becoming a critical SMT line bottleneck.

- Traceability Gaps: Automotive and medical sectors require per-chip data binding, difficult with traditional methods.

- Volume & Diversity: Shorter product lifecycles and exploding chip variants consume massive time in line change, debugging, and material prep.

Axiom-ICPP transforms the programming station from a simple tool into a strategic asset for data-driven value creation.

Core Value Pillars: Four Disruptive Advantages

1. Unmatched Throughput

Revolutionary parallel architecture with intelligent scheduling compresses programming time to the theoretical limit, keeping your SMT lines moving at full speed.

2. Unbreachable Data Integrity

Military-grade encryption, verification, and auditing from server to chip ensure absolute firmware IP security.

3. Intelligent Yield Insight

Beyond simple pass/fail. AI engine detects minute parameter shifts, proactively predicting potential defects.

4. Natively Integrated Manufacturing Flow

Seamless MES, ERP, and engineering database integration turns programming data into the lifeblood of smart manufacturing decisions.

Intelligent Core: Axiom OS & Digital Twin

- Adaptive Parameter Optimization Engine: Real-time learning and predictive yield management dynamically fine-tune voltage, clock frequency, pulse width for maximum yield.

- Full-Chain Data Security: AES-256 encryption, digital signatures, rollback prevention, and immutable audit logs.

- Smart Production Scheduler: Optimizes queues by order priority and chip type; integrates with MES and automated material handling for minimal human intervention.

- Digital Twin: Virtual debugging, remote diagnostics, and capacity simulation to shorten ramp-up and optimize production planning.

High-Performance Architecture

Speed

- High-density parallel channels: 32/64/128 per module; isolated and independent for multi-chip simultaneous programming.

- Smart power management with SiC devices for fast response and high efficiency.

- “Flying Programming”: parallel data transfer during robot handling reduces idle time by up to 40%.

Precision

- Nanosecond-level timing with high-performance FPGA.

- Real-time VCC monitoring, dynamic impedance tests, multi-layer verification (online, post-flash, CRC checks).

Flexibility

- Full protocol & package support: MCU, MPU, NOR/NAND, eMMC, UFS, FPGA, automotive SoC.

- Hot-swappable modules; adapters switch within 30 seconds.

Modular Ecosystem: Comprehensive Programming Solution

- Integrated laser marking and code reading.

- Online functional testing and calibration.

- Automated material handling system for “lights-out” production.

- Smart manufacturing & traceability engine (SECS/GEM, OPC UA, Hermes).

- Environmental simulation and aging test suite (-40°C to +125°C optional).

Unparalleled Reliability

- Industrial-grade components; MTBF >100,000 hours.

- Multi-level cooling architecture (chip, module, system); optional liquid cooling.

- EMC compliance (CE/FCC); stable in complex environments.

- Axiom Care: 24/7 global support, predictive maintenance, global spare parts, firmware & software updates.

Technical Specifications

| Parameter | Axiom-ICPP Detailed Specs |

|---|---|

| System Architecture | Axiom OS (Linux RTOS), Xilinx UltraScale+ MPSoC, modular, hot-swappable |

| Programming Performance | 256 standard channels (expandable to 1024), 1.2V–5.0V adjustable per channel, max frequency 200MHz, <3.5s full-chip verification for 1Gb SPI NOR Flash |

| Supported Devices | MCU/MPU (ARM, RISC-V, Power Architecture, TriCore), Memory (NOR/NAND, eMMC, UFS, SD/MicroSD, MRAM), CPLD/FPGA, Automotive SOC |

| Data Security | AES-256/RSA-2048 encryption, Hardware Root of Trust, FDA 21 CFR Part 11 / ISO 27001 audit compliance |

| Automation Interfaces | Robot: EtherCAT/PROFINET; Communication: SECS/GEM, OPC UA, MQTT, TCP/IP; Barcode scanner: USB/RS-232 |

| Physical & Environment | Power: 200–480V AC, 50/60Hz, max 3kVA; Operating Temp: +10°C–+40°C; Storage Temp: -20°C–+70°C; Dimensions: 600mm(W)×800mm(D)×1800mm(H) |

Call to Action: Towards Zero-Defect Programming

Don’t Just Program. Empower. Secure. Trace.

Axiom-ICPP is the ultimate solution for software-defined manufacturing challenges.Schedule Technical ConsultationRequest Free Programming AssessmentDownload Smart Programming Whitepaper