Tray packing is a common packaging method in SMT supply chains—especially for fragile, odd-shaped, or large SMD components that are not suitable for tape-and-reel. Choosing the right tray machine affects part protection, throughput, feeder compatibility, inspection accuracy, and overall production cost. This guide explains tray types, machine categories, selection criteria, integration tips, common pitfalls, and maintenance best practices.

Contents

1. Why Use Tray Packing Instead of Tape-and-Reel?

Tray packing offers better physical support and protection for bulky, heavy, or delicate parts (e.g., connectors, ceramic parts, QFPs). Use trays when pocket-forming or cover-tape would risk deformation or when automated tray feeders are already in your assembly line.

2. Common Tray Types and Materials

2.1 Plastic (PS / PET / PP) Trays

Rigid plastic trays (PS, PET, PP) are widely used — they are low-cost, recyclable (depending on material), and available in many cavity geometries.

2.2 Foam and ESD-Safe Trays

For moisture-sensitive or electrostatic-sensitive components, use ESD-safe foam or conductive trays to mitigate handling risks.

3. Tray Machine Categories

3.1 Manual & Semi-Automatic Tray Packers

Suitable for low-volume or mixed-production lines—operators load parts into cavities and the machine may perform indexing and sealing. Semi-automatic options can increase throughput without the capital expense of full automation.

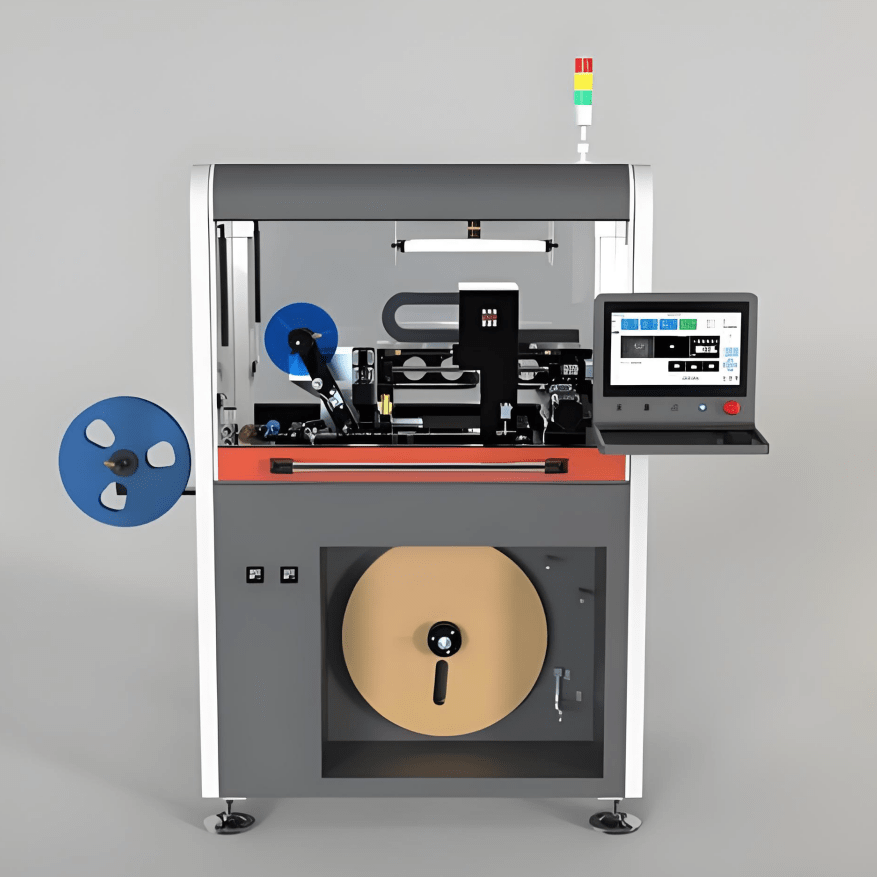

3.2 Fully Automatic Tray Packing Lines

High-volume factories choose fully automatic lines: part feeding → vision inspection → case placement → tray indexing → sealing/stacking. These systems integrate with MES/WMS and deliver consistent speed and lower labor cost per part.

4. How to Choose: 9 Selection Criteria

Below are the most important factors when selecting a tray machine:

- Part geometry & fragility. Confirm tray cavity matches part; custom tooling may be needed.

- Throughput target. Determine pieces per hour and select a machine class that meets (or slightly exceeds) this target.

- Feeder & pick-and-place compatibility. Ensure trays can be fed to your pick-and-place or that feeders accept your tray format.

- Inspection requirements. If orientation/polarity matters, pick a machine with integrated vision or plan for inline inspection.

- ESD and moisture considerations. Choose conductive trays or include desiccant/packaging for MSL parts.

- Flex tooling vs. dedicated tooling. Flex tooling reduces cost for mixed SKUs but may lower throughput vs. dedicated molds.

- Integration & data (barcodes/traceability). Look for labeling/inkjet/barcode capability and MES/WMS APIs.

- Maintenance & spare parts availability. Prefer vendors with local support or common spare parts to reduce downtime.

- Budget & ROI. Estimate total cost of ownership: capex + labor + downtime + consumables.

Quick checklist to bring to vendors

- Primary part dimensions & tolerances

- Daily/weekly volume targets

- ESD / MSL level

- Required labeling/tracking format

- Connectivity/MES requirements

5. Integration: Feeders, Pick-and-Place & MES

Tray machines should be selected with downstream processes in mind—tray format must match feeder loading mechanics or robotic pick heads. Also ensure the machine can add barcodes/labels or export quantity/lot data to your MES for traceability.

6. Quality Control & Inspection

Inline vision inspection at the packing stage prevents mis-packed trays and reduces wasted downstream cycles. Common checks include presence/absence, orientation, polarity marks, and barcode verification.

7. Cost Considerations & Maintenance

Factor in tooling costs (custom cavity molds), consumables (spacers, adhesive, lids), preventive maintenance plans, and spare parts. A small productivity gain from a better machine can often pay back tooling costs within months in high-volume environments.

8. Common Pitfalls & How to Avoid Them

- Buying underspecified machines for anticipated growth → plan 20–30% headroom.

- Ignoring feeder compatibility → request a demo with your pick-and-place.

- Skipping proper ESD controls for sensitive parts → leads to latent failures.

- Underestimating tooling lead time → prototype cavity tooling early in development.

9. Vendor Evaluation: What to Ask

Ask vendors for: on-site demo, reference installations, average MTTR (mean time to repair), spare-parts list, tooling turnaround time, and firmware/MES integration documentation.

10. Short Case Study (Example)

A small EMS provider switching from manual tray loading to a semi-automatic tray packer increased throughput by 3× while reducing part damage by 70%—main changes were addition of a vision check and custom cavity tooling to secure leads.

11. Further Reading & Related Guides

下面列出的内链均指向 SMT PACK LAB 网站上已存在的文章或标签页,以便你深入阅读并对比 taping 与 tray 方案:

- Taping Machines & Tray Packers — FAQ & Guide. :contentReference[oaicite:0]{index=0}

- How to Choose the Right Taping Machine for Your SMT Line(对比 tape-and-reel 选择要点)。 :contentReference[oaicite:1]{index=1}

- How to Optimize Taping Efficiency in Low-Volume PCB Production(理解 tape 与 tray 的效率权衡)。 :contentReference[oaicite:2]{index=2}

- Differences Between Manual, Semi-Automatic, and Fully Automatic Taping Machines(了解自动化级别对决定 tray vs. tape 的影响)。 :contentReference[oaicite:3]{index=3}

- Tray Packing (Tag)(更多 tray 相关文章汇总)。 :contentReference[oaicite:4]{index=4}

12. Conclusion

选择合适的 tray machine 关键在于将 零件特性、产量目标、下游设备兼容性、检验需求 与预算综合考量。通过向供应商提供详尽的规格并要求带料 demo,可以显著降低采购风险并确保系统上线后的产线稳定性。 需要帮助?联系我们获取设备选型建议

© SMT PACK LAB • For help selecting tray or taping machines, custom tooling, or integration with your pick-and-place line, contact us.

留下评论