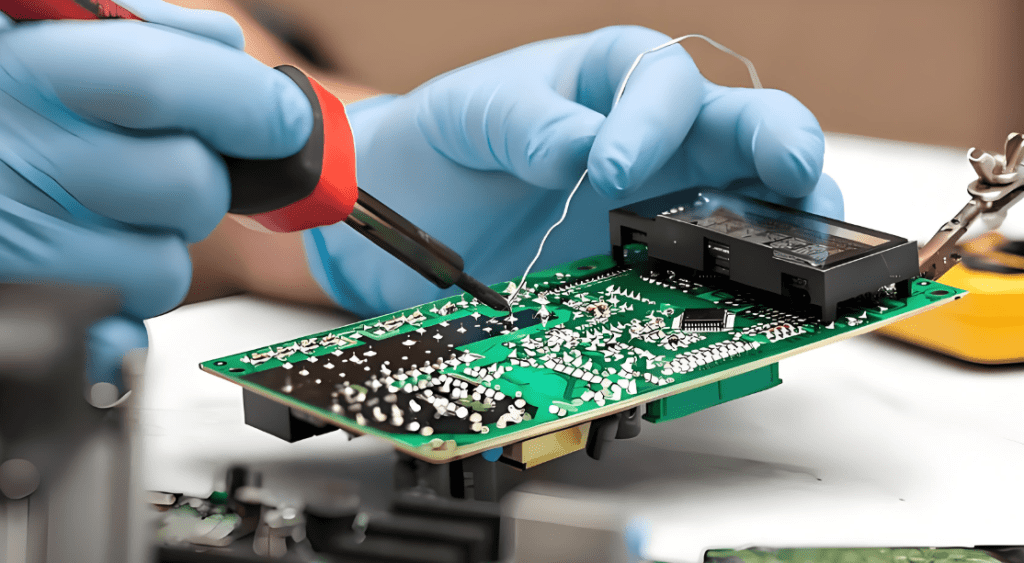

Manual soldering and manual handling remain a major source of defects for small SMT factories: cold joints, bridging, tombstoning, component damage and inconsistent yields. This guide explains—step by step—how automation (taping, tray packing, pick-and-place, reflow ovens, AOI/X-ray, vision systems) eliminates or mitigates those human error vectors, what to measure, how to select equipment, and how to implement changes with minimal disruption.

Estimated read: 12–18 min • Target audience: small SMT shops, production managers, QA engineers

ContentsExecutive SummaryCommon Human Errors in Manual SolderingAutomation → Which Error It SolvesEquipment Selection: Practical ChecklistIntegration & Implementation RoadmapKPIs & ROI CalculationShort Case Study (Small Factory)Maintenance, Training & Change ManagementPitfalls to AvoidFAQsRelated Reading

Executive Summary

Human manual soldering errors are typically symptoms of upstream problems: inconsistent feeding, incorrect component orientation, poor solder paste control, and manual placement variability. Automated SMT equipment addresses these by standardizing feeding (taping & tray packing), automating accurate placement (pick-and-place), controlling solder profiles (reflow ovens), and detecting defects early (AOI/X-ray). For small factories the goal is pragmatic: prioritize high-impact automation (pick-and-place + reflow + AOI) and use semi-automation (taping/tray) where full automation is not cost-effective.

Tip: start with the error modes that occur most frequently or cost the most in rework—target those first for automation.Common Human Errors in Manual Soldering

1. Typical failure modes

- Cold joints: insufficient solder volume or poor wetting due to inconsistent solder paste deposition or manual soldering technique.

- Solder bridging: excessive solder or misalignment between pads during hand placement.

- Tombstoning: occurs when asymmetric wetting/heat causes one end to lift.

- Component damage: mechanical stress (bending, chipping) during manual handling.

- Orientation/rotation errors: passive polarity or IC rotation mistakes.

- Operator fatigue/skill variance: inconsistent results across shifts.

2. Why small factories are especially vulnerable

Small shops typically have mixed-model production, frequent changeovers, limited automation, and higher dependence on manual work. They also often lack strict SOPs, environmental controls (humidity/ESD), and real-time QC—amplifying small human mistakes into yield loss.Automation → Which Error It Solves

How each automation class reduces errors

| Automation | Primary human errors addressed | How it fixes them (technical) |

|---|---|---|

| Taping & Tray Packing | Feeder misfeeds, orientation errors, handling damage | Standardizes orientation/spacing; reduces manual handling; integrates with feeders for accurate delivery. |

| Pick-and-Place | Placement offset, rotation, tilt | High-precision motion + vision correction places components within microns; reduces tilt/tombstone via nozzle control and placement force profiling. |

| Solder Paste Printer (Stencil) | Inconsistent solder volume → tombstoning, insufficient joints | Consistent paste volume and alignment using inspection and fine-pitch stencils; automated squeegee control. |

| Reflow Oven | Cold joints, flux residues, inconsistent soldering | Controlled thermal profiles (PID controllers) ensure correct heating ramp & soak; conveyor speed control for repeatability. |

| AOI / SPI / X-ray | Undetected defects (bridges, tombstones, voids) | Automated optical and X-ray detection identifies defects early; integrates with feedback to adjust paste printers or reject bins. |

| Vision & AI Systems | Misreads, orientation mistakes, foreign objects | Real-time verification, pattern recognition, anomaly detection; reduces operator dependency for visual inspection. |

Prioritization for small factories

Order of impact (typical small-factory ROI):

- Pick-and-place + vision calibration

- Solder paste control (printer + SPI)

- Reflow oven with programmable profiles

- AOI for post-reflow inspection

- Taping/tray automation (if feeders and parts mix are large)

Equipment Selection: Practical Checklist

1. Match equipment to real error modes

Start from the defects you see daily. If tombstoning and tombstone-related rework dominate, prioritize stencil/paste + pick-and-place calibration. If misfeeds and component damage are common, invest in taping/tray packing.

2. Detailed selection checklist

- Placement accuracy: specify absolute placement repeatability (µm). For 0201/01005, aim for ±25µm or better.

- Vision capabilities: auto fiducial recognition, multi-angle inspection, high-resolution cameras.

- Nozzle & vacuum options: variety of nozzle types, vacuum control to prevent component tilt/damage.

- Feeder compatibility: tape, tray and stick feeders; quick-change feeders reduce changeover time.

- Solder paste printer: SPI integration option, stencil exchange speed, fine-pitch capability.

- Reflow oven: zoned heating, programmable profiles, conveyor speed precision, nitrogen purge option for QFP/BGA.

- AOI/SPI: second-op AOI (post-reflow) and SPI (post-print) for closed-loop control.

- Data & connectivity: MES/SMT line connectivity (CSV/OPC UA/MQTT) for traceability and SPC charts.

- Footprint & modularity: can you add modules later? Start modular if budget-limited.

3. Vendor evaluation

Ask vendors for:

- Demo runs with your real components (bring 10–20 representative reels/trays)

- Reference sites (preferably small factories)

- Support SLA, spare parts list, typical MTTR

- Training plan and on-site commissioning cost

- Integration examples with existing feeders, conveyors, MES

Request a demo with your components →Integration & Implementation Roadmap

Phase 0 — Baseline measurement

Log defect types, hours lost, rework cost and time for 2–4 weeks. You must quantify where automation will pay off.

Phase 1 — Pilot cell

- Install 1 pick-and-place, printer and reflow in a pilot cell

- Run 10 representative SKUs, measure CPY (first pass yield), cycle time, changeover time

- Calibrate vision/nozzles and document settings

Phase 2 — Closed-loop QC

Add SPI (post-print) and AOI (post-reflow) to create feedback loops that automatically flag and correct paste/placement deviations.

Phase 3 — Rollout & scale

Gradually replace manual steps across lines, update SOPs, and track KPIs continuously.

Quick timeline (typical small shop)

| Activity | Duration |

|---|---|

| Baseline & supplier evaluation | 2–4 weeks |

| Pilot cell build & testing | 4–8 weeks |

| Closed-loop QC addition | 2–6 weeks |

| Shop-wide rollout | 3–9 months (phased) |

KPIs & ROI Calculation

Key KPIs to track

First Pass Yield (FPY)

Defects per Million Opportunities (DPMO)

Mean Time to Repair (MTTR)

Machine Uptime (%)

Changeover Time

Simple ROI example (numercial)

Assume:

- Daily PCBs: 500

- Current manual rework cost: $0.50/board (average)

- Manual rework loss/day = 500 * $0.50 = $250

- Automation reduces rework by 80% ⇒ savings ≈ $200/day ⇒ $50k/year (250 days)

- Estimated cost for pick-and-place + printer + reflow for small cell: $120k

- Payback time ≈ 120k / 50k ≈ 2.4 years (not including productivity improvements & quality gains)

Include additional benefits: reduced labor, improved on-time delivery, lower warranty costs—these shorten payback.Short Case Study (Small Factory)

Background

10-person contract manufacturer producing mixed low-volume PCBs (avg. 400 boards/day). Common defects: tombstoning (1.2%), bridges (0.9%), and misplacements (1.5%).

Intervention

- Installed a pilot pick-and-place + SPI + reflow cell.

- Introduced taped feeders and standardized trays for common SKUs.

- Implemented AOI after reflow for critical boards.

- Operator upskilling and SOP documentation.

Results (6 months)

- Tombstoning reduced from 1.2% → 0.15%

- Total defect rate dropped by 72%

- FPY increased from 93% → 98.6%

- Rework labor hours cut by 60%

This illustrates measurable impact even for small factories when automation is targeted at the root causes.Maintenance, Training & Change Management

Maintenance

- Daily: clean nozzles, optics, check belts & feeders.

- Weekly: verify calibration, run diagnostic board.

- Monthly: replace consumables, update software/vision models.

Training

- Documented calibration recipes per SKU (nozzle offsets, placement force, reflow profile)

- Operator certification: shadow shifts, supervised runs, periodic recertification

- Knowledge base with photos, error examples and corrective actions

Change Management

Small factories must involve operators early, measure improvements publicly (display FPY), and schedule phased automation so staff can adapt.Pitfalls to Avoid

- Buying “too big” equipment beyond real needs—leads to underutilization.

- Skipping pilot runs with your real components—vendors’ demo parts mask edge cases.

- Poor SOP documentation—automation without discipline yields variable results.

- Ignoring environmental controls (ESD/humidity)—automation amplifies some process errors if environment is poor.

- Not planning for spare parts and support SLA—downtime costs can erase ROI.

FAQs

Q: Will automation completely remove all manual soldering?

A: No—automation aims to eliminate the most error-prone manual steps. Hand soldering may still be used for prototypes, touch-ups, or special connectors.

Q: How soon can a small shop see results?

A: Pilot results (reduced rework and FPY improvements) are often visible within weeks of commissioning a pilot cell. Full shop-wide benefits take months as SOPs and operator skills mature.

Q: Do I need MES integration to get benefits?

A: Not necessary for initial gains—local closed-loop (SPI→Printer, AOI→Printer/Placement adjustments) delivers most quality improvements. MES adds traceability and long-term SPC benefits.Related Reading

- How to Optimize Taping Efficiency in Low-Volume PCB Production

- Choosing the Right Tray Packing Machine for Miniature Components

- Understanding Pick-and-Place Calibration for Precision Assembly

- Hidden Factors Affecting SMD Component Yield in Small Factories

Quick Checklist

- Log defect types (2–4 weeks)

- Run pilot with real SKUs

- Prioritize pick-and-place + printer

- Add SPI/AOI for closed-loop control

- Track FPY & DPMO weekly

Top Metrics to Display

FPY

DPMO

MTTR

Uptime

留下评论