Redefining Precision, Empowering Your Digital Factory

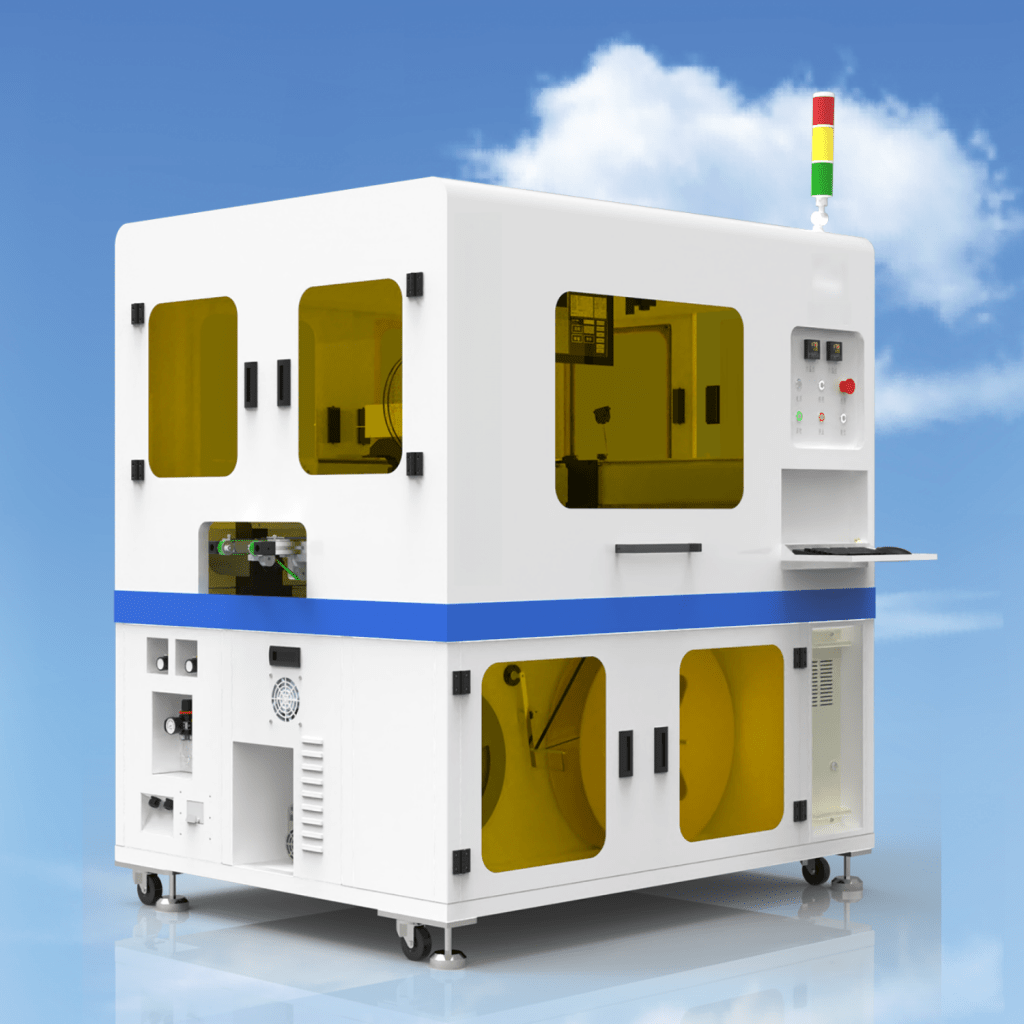

The Axiom Series intelligent tape-and-reel system goes beyond packaging — it is a strategic asset designed for seamless traceability, quality elevation, and full integration into smart manufacturing. Built for global EMS leaders and distributors pursuing zero defects, extreme efficiency, and ultimate flexibility.

🔬 Submicron Precision ±15μm accuracy for 01005 and beyond

🤖 Self-learning Intelligence powered by Axiom AI

⚙️ Modular Expansion Laser marking, in-line programming, AOI

🌐 Industry 4.0 Ready Native MES/ERP integration

🛠️ Global Support Network 24/7 expert service worldwide

Challenges and Solutions

Are you facing the following challenges in modern manufacturing?

- Component Miniaturization: 0201, 01005, even 008004 push the limits of precision and yield control.

- Traceability Requirements: Automotive and medical sectors demand full traceability from die to product.

- Lack of Flexibility: Frequent changeovers lead to major productivity losses in high-mix, low-volume production.

- Data Isolation: Legacy systems create data silos, obscuring OEE and process insights.

- Post-Process Bottlenecks: Separate marking, testing, and programming stages increase handling risk and cost.

The Axiom Series is more than a taping machine — it is your strategic gateway to smart manufacturing, transforming packaging into a unified hub of quality validation, data integration, and operational intelligence.

Core Advantages — The Four Pillars of Value

1. The Intelligent Core

Powered by Axiom OS, the system sees, understands, and optimizes through machine learning and computer vision.

2. Uncompromising Performance

Driven by linear motors and ultra-rigid structures, achieving over 40,000 UPH with submicron precision — a perfect balance of speed and accuracy.

3. Limitless Configuration

Like a bespoke performance car, every Axiom system is tailored — from entry-level models to fully equipped production centers.

4. Seamless Ecosystem Integration

Native SECS/GEM, OPC UA, and MTConnect support make Axiom an open, reliable data node in your digital factory.

Axiom OS and Digital Twin — The Intelligent Core

Axiom OS is more than control software — it’s a cognitive system for operation, analysis, and optimization.

- Adaptive Control: Learns material properties in real time and dynamically tunes pickup and placement parameters for gentle, precise handling.

- Predictive Maintenance: Monitors vibration, temperature, and current of key components to forecast failures hundreds of hours ahead.

- Recipe Intelligence: Auto-recognizes materials via RFID and applies optimal parameters for zero-downtime changeovers.

- Data Cockpit: Real-time visualization of OEE, CPK, and UPH metrics on an intuitive HD touchscreen dashboard.

Digital Twin Integration

- Virtual Commissioning: Simulate, debug, and train before equipment arrives on site.

- Remote Expert Access: Engineers can securely connect to live digital twins for diagnostics and optimization.

- Process Simulation: Detect potential mechanical or vision conflicts before production starts.

Unmatched Performance — Precision, Speed, and Flexibility

Precision

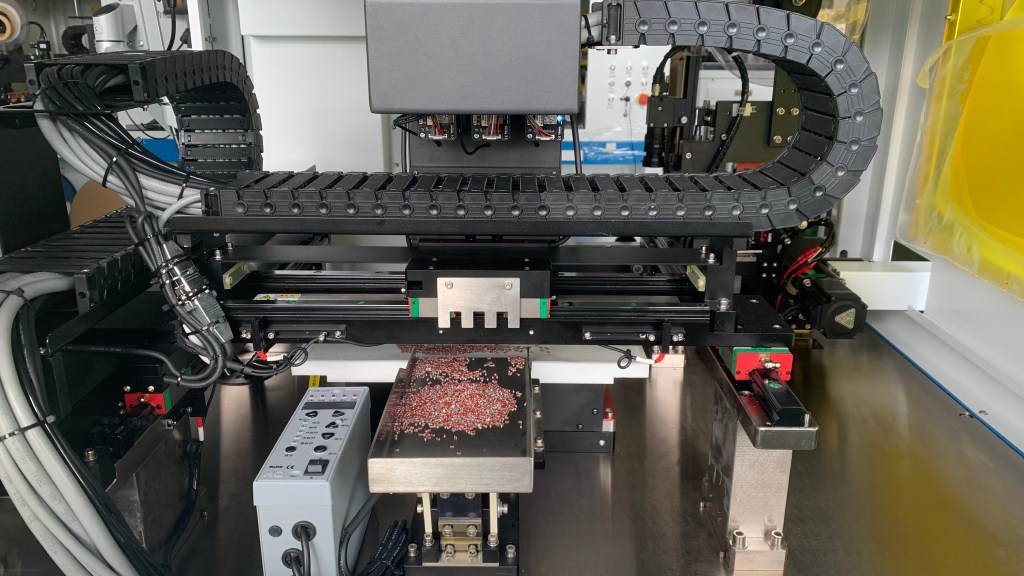

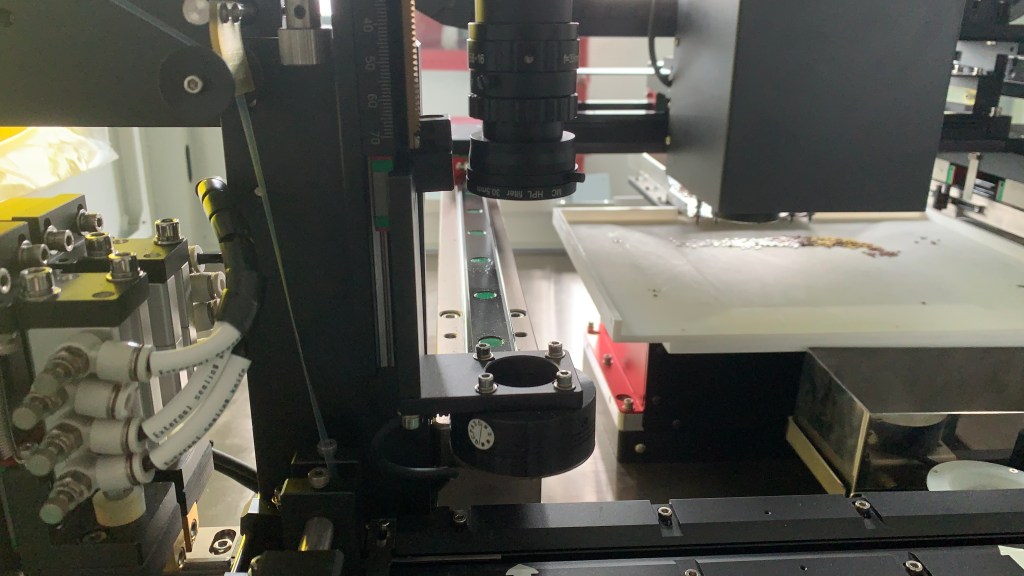

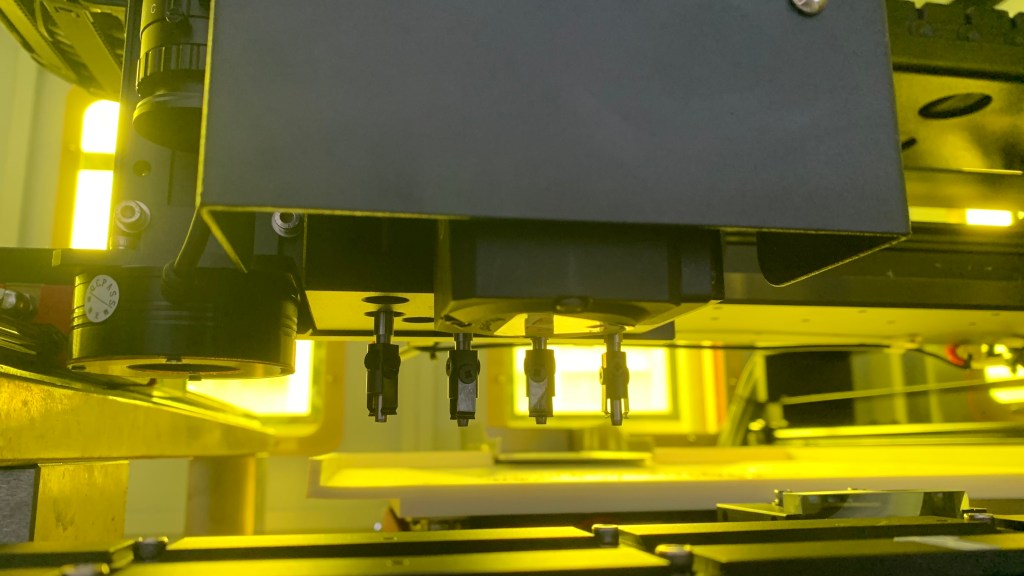

10MP global shutter cameras with multi-angle lighting deliver ±15μm accuracy. Linear motors achieve ±5μm repeatability with closed-loop thermal stabilization.

Speed

Parallel dual-head architecture and AI-optimized motion paths push throughput beyond 60,000 UPH, eliminating idle cycles.

Flexibility

Supports everything from 008004 chips to large connectors via magnetic quick-change tooling. Recipe-based setup cuts changeover to under 5 minutes.

Modular Function Library — Build Your Custom Solution

- Integrated Laser Marking: Fiber laser engraving of QR codes, logos, and serials at 0.01 mm precision for full traceability.

- In-line Programming & Functional Test: Multi-channel IC programming with live verification ensures “ready-to-use” delivery.

- Omni-directional AOI: Combines 2D/3D inspection for coplanarity, polarity, and surface defects with SPC data feedback.

- MES/ERP Integration: Native SECS/GEM, OPC UA, MQTT for real-time bi-directional data exchange.

- ESD & Cleanroom Package: Anti-static construction with optional HEPA filtration meeting ISO Class 5–8 standards.

Unrivaled Reliability and Service

Engineering Excellence: Hybrid granite-polymer base for vibration damping and thermal stability. All linear motors, bearings, and guides from top-tier German and Japanese brands.

Axiom Care Global Program:

- 24/7/365 worldwide technical support from hubs in Asia, Europe, and North America.

- Predictive maintenance services powered by cloud-based analytics.

- Global spare parts logistics with 48-hour delivery commitment.

- Continuous Axiom OS updates for evolving performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Speed | Up to 40,000 UPH (standard), up to 60,000 UPH (dual-head) |

| Placement Accuracy | ±15μm |

| Repeatability | ±5μm |

| Component Range | 008004 – 45mm |

| Vision System | 10 MP camera, RGBW ring lighting, deep learning algorithms |

| Motion System | Linear motor drive, nano-scale encoder feedback |

| Options | Laser Marking, IC Programming, 2D/3D AOI, MES Integration |

| Power | 400–480V AC, 50/60Hz |

| Air Supply | 0.6–0.8 MPa, clean dry air |

| Weight | Approx. 650 kg |

Ready to Forge the Future of Manufacturing?

The Axiom Series is not just a machine — it’s your strategic partner in Industry 4.0, engineered to keep you ahead in global competition.

Book a Technical ConsultationRequest Sample EvaluationDownload Technical Whitepaper

Product Details