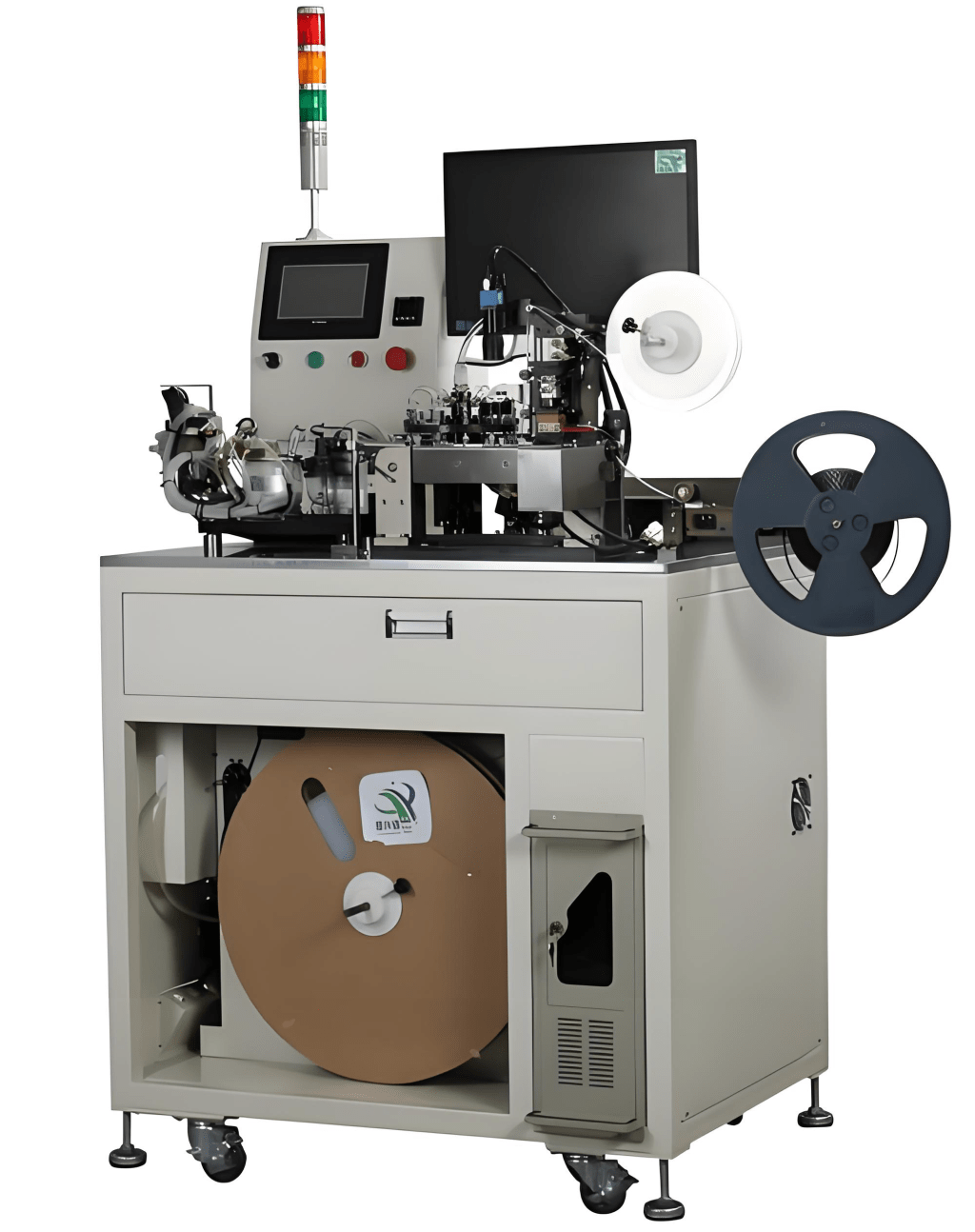

Installing a tray loader correctly is crucial for improving SMT production efficiency, preventing misfeeds, and ensuring smooth operation. This guide provides five practical steps to install and calibrate your tray loader for maximum yield and reliability. Keywords like tray loader setup, SMT optimization, sensor calibration, and workflow efficiency are integrated throughout.

Step 1: Prepare the Tray Loader and Machine

Details

Before installation, ensure the tray loader is fully functional and the SMT machine is powered off. Gather all tools, calibration equipment, and anti-static protection.

- Verify tray loader model and components

- Check SMT machine power and firmware

- Prepare calibration tools and antistatic gear

- Ensure proper working environment for installation

Step 2: Position the Loader Correctly

Details

Place the tray loader in the designated slot of the SMT line. Ensure the feed path aligns with pick-and-place components and the tray orientation matches the machine requirements.

- Align loader rails with machine feeder slots

- Check tray orientation and pick-up points

- Ensure no obstacles in the feed path

- Verify mechanical fit and stability

Step 3: Align Sensors and Feed Path

Details

Proper sensor alignment ensures components are detected correctly. Adjust optical and mechanical sensors, verifying each with sample trays before starting production.

- Calibrate optical sensors against tray positions

- Check mechanical switches for accurate triggers

- Verify component spacing along feed path

- Run preliminary detection tests

Step 4: Adjust Loader Settings

Details

Adjust tray loader speed, pick height, and other operational parameters. Document settings to maintain consistency for future production runs.

- Set speed and acceleration parameters

- Adjust pick-up height and alignment

- Verify tension and movement consistency

- Save settings in MES or machine memory

Step 5: Conduct Test Runs

Details

Run trial batches using sample components. Monitor errors, adjust as needed, and confirm MES logs for accurate production tracking.

- Perform short test runs

- Record errors and fine-tune parameters

- Confirm tray alignment and sensor accuracy

- Ensure MES records correct component counts

Conclusion

Following these five steps ensures the tray loader is installed efficiently, improves SMT line yield, reduces misfeeds, and enhances overall production reliability. Proper calibration, sensor alignment, and operational consistency are key to optimal SMT workflow.

For more SMT guidance, visit Home Page or Contact Us.

留下评论