Tape and reel machines are essential in SMT assembly lines for feeding components efficiently and reliably. Despite advanced automation, operators may encounter various issues that can cause misfeeds, downtime, or defective placement. Understanding the common problems and resolving them promptly is crucial for maintaining production efficiency and quality.

- Introduction

- Common Issues

- Troubleshooting Steps

- Operator Guidelines

- Preventive Maintenance

- Case Studies

- Conclusion

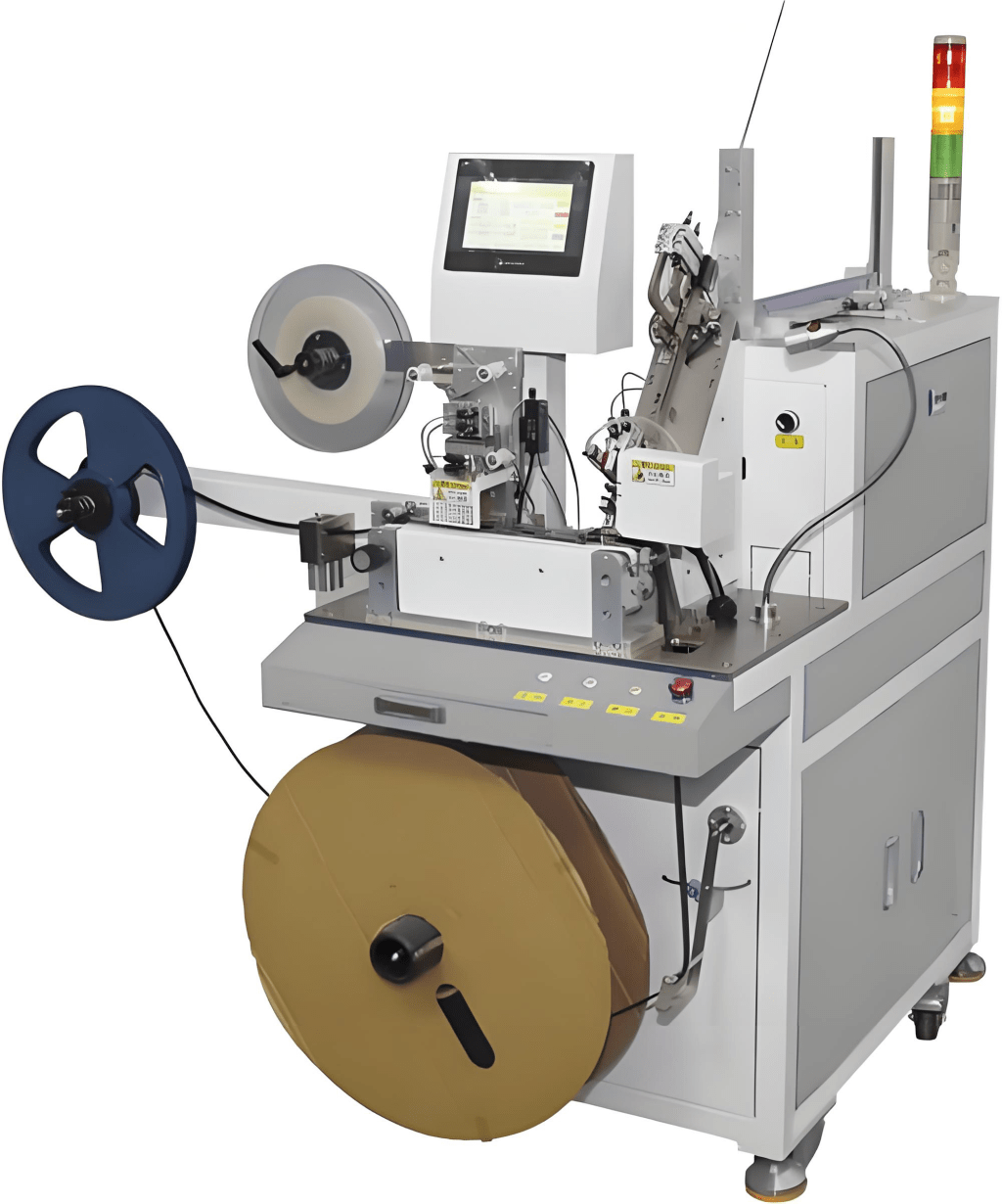

Introduction

Tape and reel machines are essential in SMT assembly lines for feeding components efficiently and reliably. Despite advanced automation, operators may encounter various issues that can cause misfeeds, downtime, or defective placement. Understanding the common problems and resolving them promptly is crucial for maintaining production efficiency and quality.

Common Issues

Operators often face several types of tape and reel machine issues. Some of the most frequent problems include:

1. Tape Misalignment

Misaligned tape can prevent components from being picked correctly. It usually occurs due to improper feeder loading or worn guides. Regular inspection of the tape path helps prevent this issue.

2. Incorrect Tape Tension

Tension that is too tight or too loose can lead to feeding errors, misfeeds, or component damage. Always adjust tape tension according to the machine manual before starting production.

3. Component Orientation Errors

Components placed incorrectly in the carrier tape can cause placement errors. Verification during loading, or using vision systems, can reduce orientation faults.

4. Sensor Malfunction

Faulty sensors may fail to detect tape presence or component positions. Regular calibration and cleaning of sensors are required to ensure accurate detection.

Troubleshooting Steps

Step 1: Inspect the Tape Path

Check for any debris, twists, or misfeeds in the tape path. Clean rollers and guides as necessary.

Step 2: Verify Component Orientation

Manually or visually inspect components in the tape to confirm correct orientation. Adjust feeder or rotate components if required.

Step 3: Adjust Tape Tension

Use machine-specific settings to correct tension. Test feeding after adjustment to ensure smooth operation.

Step 4: Sensor Check

Clean all sensors and verify functionality. Replace malfunctioning sensors to prevent misfeeds.

Operator Guidelines

- Follow SOP for loading tapes correctly.

- Inspect tapes for damage or defects before use.

- Document recurring issues to facilitate continuous improvement.

- Ensure operators are trained on troubleshooting and preventive maintenance.

Preventive Maintenance

Scheduled maintenance can prevent most common issues. Recommended schedules include:

- Daily: Clean tape path, check rollers and guides, verify tape alignment.

- Weekly: Inspect belts, lubricate moving parts, calibrate tape tension.

- Monthly: Conduct full inspection, test sensors, review logs, replace worn components.

Case Studies

Example: A production line faced repeated tape misfeeds due to worn tape guides. After replacing guides and training operators on loading procedures, misfeed errors dropped by 85%, improving production efficiency and yield.

Conclusion

Addressing common tape and reel machine issues requires systematic troubleshooting, operator training, and preventive maintenance. By implementing the steps outlined in this guide, SMT lines can maintain smooth component feeding, reduce downtime, and improve product quality.

For additional resources, visit our Home Page or Contact Us page.

留下评论