1. Introduction

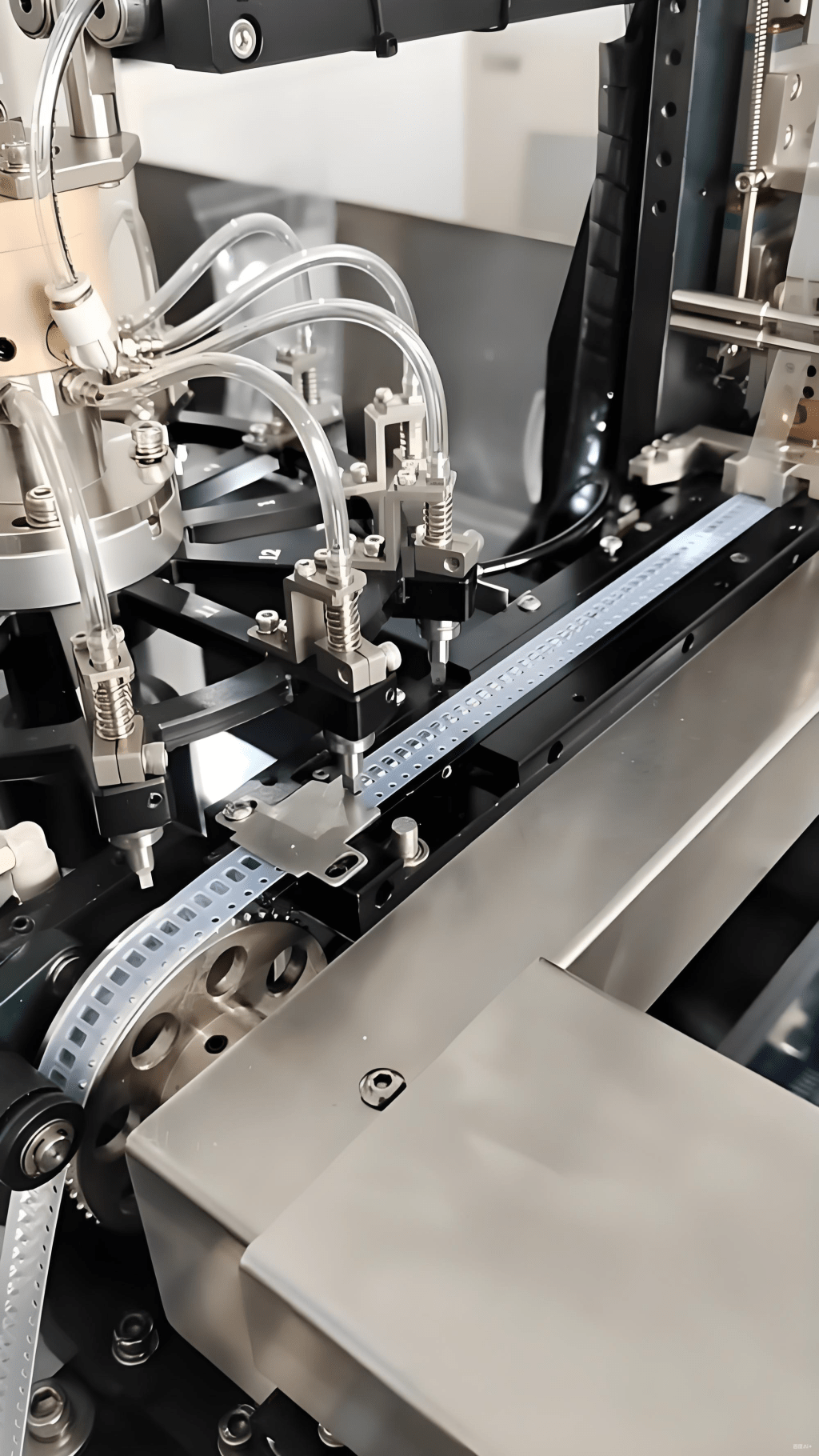

The tape and reel process is a cornerstone of modern SMT packaging. Maintaining these machines properly ensures consistent component positioning, prevents line downtime, and safeguards your yield rate. Whether you operate a manual, semi-automatic, or fully automated taping system, following structured maintenance practices can extend machine life and stabilize production.

Table of Contents

- 1. Introduction

- 2. Why Maintenance Matters in SMT Taping

- 3. Daily Maintenance Procedures

- 4. Weekly and Monthly Preventive Tasks

- 5. Troubleshooting Common Problems

- 6. Safety Guidelines and Machine Handling

- 7. Operator Training & Standard Operating Procedures (SOP)

- 8. MES Integration and Data Logging

- 9. Case Study: Improving Uptime Through Preventive Care

- 10. Key Takeaways and Continuous Improvement

- 11. Contact & Internal Resources

This guide provides a step-by-step strategy for machine maintenance, combining real-world factory practices, engineering analysis, and operator experience.

💡 Tip: A well-maintained tape and reel machine can reduce rework rates by over 25% and extend equipment lifespan by several years.

2. Why Maintenance Matters in SMT Taping

Neglecting maintenance leads to frequent stoppages, poor sealing quality, and inconsistent pocket depths. In high-mix, low-volume PCB environments, such as prototype or automotive sectors, downtime can directly impact project delivery and customer satisfaction.

2.1 Machine Wear Factors

- Continuous vibration and friction on the reel drive shaft.

- Heat cycles in the sealing unit degrading Teflon layers.

- Dust accumulation on optical sensors and pocket alignment zones.

2.2 Benefits of Preventive Maintenance

- Minimized tape misfeeds and pocket damage.

- Improved consistency in reel sealing temperature and pressure.

- Enhanced operator safety and production efficiency.

3. Daily Maintenance Procedures

View Daily Maintenance Tasks

Perform these checks before every production run to ensure machine stability:

- Clean the tape path and pocket cavities with antistatic wipes.

- Inspect cover tape feed rollers for uneven wear or glue residue.

- Run a sample reel and verify seal strength and alignment.

- Ensure vacuum sensors are responsive and reject gates function properly.

- Check the emergency stop and safety guards are operational.

4. Weekly and Monthly Preventive Tasks

Expand Preventive Maintenance Plan

4.1 Weekly Checklist

- Lubricate linear guide rails and reel tensioners with manufacturer-approved oil.

- Test all limit switches for signal stability.

- Review production logs to identify repeating alarm codes.

4.2 Monthly Checklist

- Inspect the sealing head temperature uniformity using an IR thermometer.

- Replace worn belts, O-rings, and heat-resistant tapes.

- Clean fan filters and electrical cabinet interiors.

- Perform calibration for optical alignment sensors.

5. Troubleshooting Common Problems

Even with proper care, issues can arise. Identifying the root cause quickly minimizes production downtime.

5.1 Tape Misfeed or Jam

- Check tape tension setting—too tight can cause slippage.

- Verify feed sprocket alignment with the pocket track.

- Ensure humidity control in the production area (40–60% RH).

5.2 Sealing Defects

- Inspect cover tape glue quality and reel temperature calibration.

- Replace damaged or contaminated sealing plates.

- Clean the pressure rollers with IPA before each shift.

5.3 Vision or Counting Error

- Wipe sensor lenses with lint-free cloths.

- Recalibrate the counting algorithm in the machine menu.

- Ensure lighting contrast is optimized for component detection.

6. Safety Guidelines and Machine Handling

Safety must never be compromised. Always disconnect the main power before adjusting or cleaning moving parts.

- Use ESD protection and grounded mats during component loading.

- Keep the working area dry to avoid short circuits.

- Train operators to identify early signs of malfunction, such as abnormal vibration or noise.

7. Operator Training & Standard Operating Procedures (SOP)

Expand Operator SOP

Operator skill directly affects output quality. Develop and implement detailed SOPs covering:

- Machine startup and warm-up process.

- Component verification and reel labeling.

- Post-shift cleaning and logbook completion.

- Basic error code interpretation and first-level troubleshooting.

Provide refresher training every six months to reinforce best practices.

8. MES Integration and Data Logging

Integrating your tape and reel machine into a Manufacturing Execution System (MES) provides full traceability from component feed to final reel output.

- Automatically capture reel ID, lot number, and packaging timestamp.

- Generate downtime and error analytics for predictive maintenance.

- Sync data with ERP for production performance dashboards.

MES integration not only improves traceability but also enhances quality assurance audits.

9. Case Study: Improving Uptime Through Preventive Care

At a mid-sized SMT facility, engineers implemented a digital checklist for maintenance. Within 90 days:

- Equipment downtime decreased by 35%.

- Yield increased from 96.2% to 98.7%.

- Unplanned stoppages were reduced to less than two per month.

Documenting every maintenance task in MES allowed the factory to build a reliable preventive history, guiding future upgrades and operator training programs.

10. Key Takeaways and Continuous Improvement

- Follow structured daily, weekly, and monthly routines.

- Train operators to detect problems early.

- Integrate machine data with MES to enable proactive maintenance.

- Standardize documentation for repeatability across shifts.

💬 Continuous improvement in SMT packaging depends not only on technology but on disciplined maintenance culture.

11. Contact & Internal Resources

For more detailed insights or customized SMT taping solutions, visit our homepage or contact page. You can also explore related guides on tray packing, taping design, and feeder calibration for better results.

留下评论