Introduction

Surface Mount Technology (SMT) has revolutionized electronics manufacturing, enabling highly compact, high-speed printed circuit board (PCB) assembly. As production speeds increase, maintaining consistent quality becomes crucial. Quality Control (QC) in SMT ensures that each board meets required specifications, reduces defects, and improves reliability. This article explores SMT quality control in detail, covering its importance, processes, inspection methods, automation tools, and practical best practices

The Importance of Quality Control in SMT

SMT quality control is critical for several reasons:

- Defect Prevention: Early detection of issues such as solder bridges, tombstoning, and misalignment reduces rework.

- Cost Efficiency: Preventing defective PCBs lowers scrap rates and reduces manufacturing costs.

- Customer Satisfaction: Consistent quality ensures end-user reliability and strengthens brand reputation.

- Compliance: QC helps meet industry standards like IPC-A-610, ensuring products meet regulatory requirements.

For additional insights on improving PCB assembly, see our related article on SMT efficiency improvements with automation.

SMT Quality Control Process

The SMT QC process can be divided into multiple stages:1. Incoming Material Inspection

All components and PCBs must be verified before production begins:

- Check component specifications and manufacturer certifications.

- Verify PCB quality, solder mask alignment, and copper traces.

- Use automated counting and component verification tools.

2. Solder Paste Control

Solder paste application is a critical step that influences joint quality:

- Measure paste thickness and volume using Solder Paste Inspection (SPI) machines.

- Check stencil alignment and printer calibration.

- Monitor paste consistency to prevent tombstoning and insufficient solder joints.

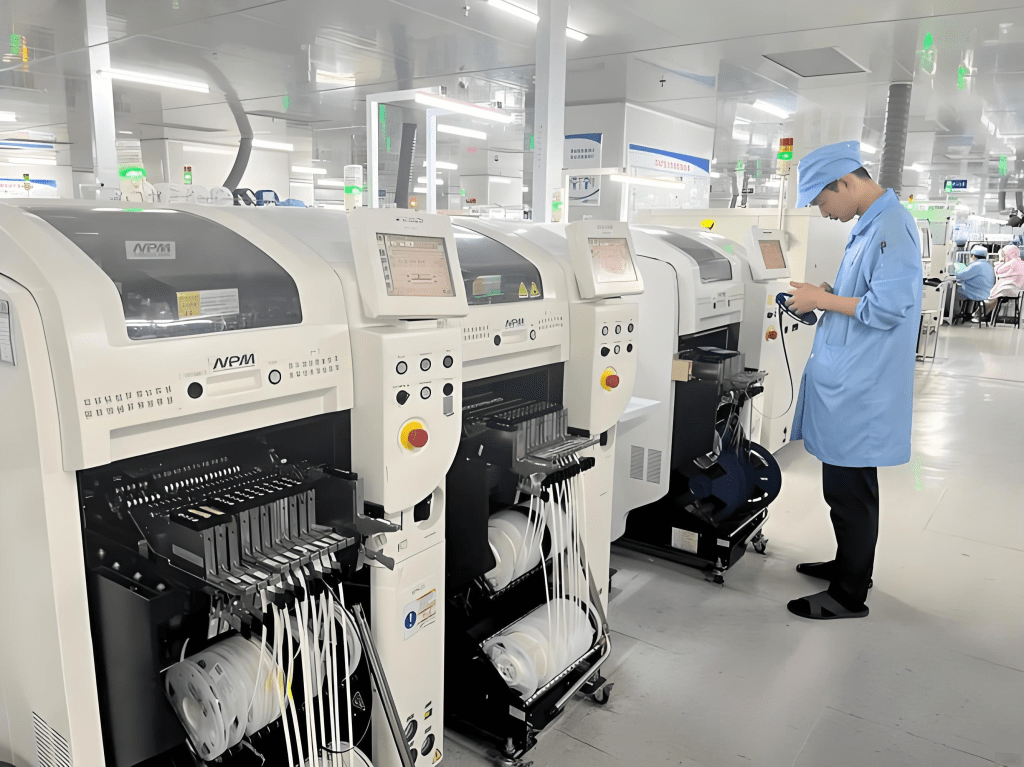

3. Placement Accuracy Verification

High-speed pick-and-place machines must position components precisely:

- Use Automated Optical Inspection (AOI) to verify component placement.

- Correct misaligned components immediately.

- Track placement accuracy statistics for each machine.

Learn more about tray machines and placement accuracy.4. Reflow and Solder Joint Inspection

After soldering, QC ensures joints are reliable:

- Visual inspection for solder defects such as voids and bridges.

- X-ray inspection for hidden solder joints, particularly BGAs.

- Temperature profile monitoring to avoid thermal stress.

Inspection Methods in SMT

Modern SMT QC relies on multiple inspection methods:

- Automated Optical Inspection (AOI): Detects missing, misaligned, or wrong components.

- X-ray Inspection: Evaluates hidden solder joints such as BGAs and QFNs.

- Functional Testing: Validates circuit performance before shipment.

- Statistical Process Control (SPC): Tracks key metrics for continuous improvement.

Automation in SMT Quality Control

Automation reduces human error and increases QC efficiency:

- AOI and SPI machines provide real-time defect detection.

- Robotic inspection stations integrate with MES for reporting and analytics.

- Predictive maintenance alerts prevent equipment failure and reduce downtime.

For insights on vision technology in SMT, check our article on SMT vision technology.

Common Challenges

QC in SMT is not without difficulties:

- Detecting very small components (01005) requires advanced AOI and magnification systems.

- Thermal profile variations can affect solder joint quality.

- High-mix production increases the risk of component misplacement.

- Integrating data from multiple inspection machines for SPC analysis can be complex.

Best Practices

To achieve effective SMT quality control:

- Maintain and calibrate AOI, SPI, and pick-and-place machines regularly.

- Train operators in inspection techniques and equipment handling.

- Use SPC and real-time monitoring to track performance metrics.

- Integrate QC systems with MES for centralized reporting.

Conclusion

Quality Control in SMT is essential for ensuring high reliability, minimizing defects, and improving overall production efficiency. By combining careful material inspection, solder paste control, placement verification, automated inspections, and real-time monitoring, PCB manufacturers can achieve consistent high-quality results while reducing costs and increasing customer satisfaction.

FAQ

What is the role of QC in SMT?

Quality Control ensures all SMT processes meet design and reliability standards, detecting defects early to prevent costly rework or failures.What machines are used for SMT QC?

Common machines include AOI systems, SPI machines, X-ray inspection systems, and automated pick-and-place machines integrated with monitoring software.How can automation improve SMT QC?

Automation reduces human error, increases inspection speed, provides real-time data, and enables predictive maintenance, leading to higher efficiency and lower defect rates.

留下评论