1. Introduction

Surface Mount Technology (SMT) production lines face continuous pressure to improve efficiency, reduce defects, and shorten production cycles. This case study demonstrates how automation solutions can optimize SMT assembly, referencing relevant techniques described in our Technical Processes section.

2. Challenge

The manufacturing line was struggling with:

- High defect rates due to manual handling

- Slow pick-and-place speed for complex components

- Inconsistent component orientation and placement

- Inefficient tray and tape feeding processes

3. Automation Solution Implemented

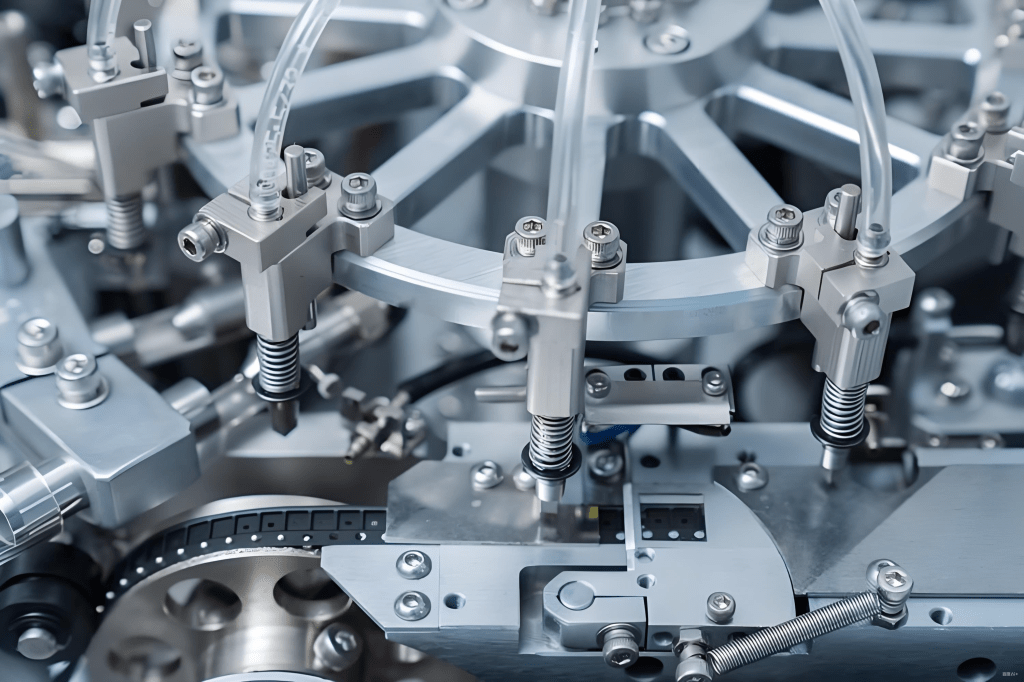

The following automation solutions were introduced:

- Automated optical inspection (AOI) systems to detect defects in real-time

- AI-driven vision technology for precise component alignment

- Tray and tape feeders integrated with pick-and-place machines

- Workflow optimization using MES (Manufacturing Execution System)

Expand: Detailed Workflow Integration

The AOI and vision systems were connected with the MES, enabling real-time data collection and predictive adjustments. Feeder automation reduced manual errors, while AI algorithms improved alignment accuracy for small SMD components.

4. Results Achieved

- 35% increase in production throughput

- Reduction of defect rates by 40%

- Labor cost savings due to reduced manual intervention

- Enhanced consistency and repeatability across production batches

5. Key Takeaways

- Integrating vision technology and AOI is crucial for defect reduction

- Automation of feeders and pick-and-place machines increases efficiency

- MES and data analytics enable predictive maintenance and process optimization

- Continuous monitoring and iterative improvements are necessary for sustained gains

6. Conclusion

This case study demonstrates that adopting automation solutions in SMT production can significantly improve efficiency, quality, and reliability. Companies aiming to stay competitive should invest in integrated vision technology, automated feeders, and intelligent data management. For further insights, visit our Technical Processes section or Contact Us for professional consultation.

Contact Us to implement SMT automation solutions in your production line.

留下评论