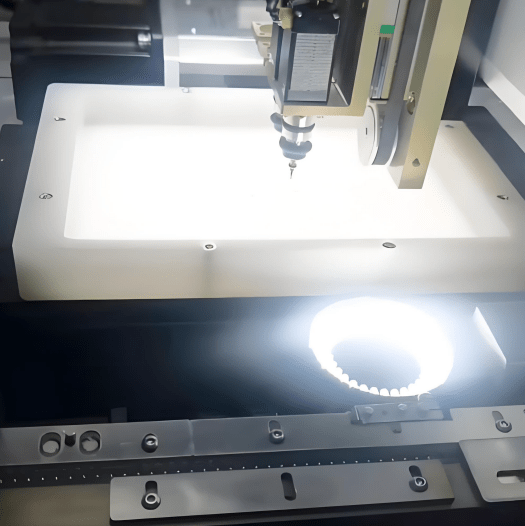

Vision technology in SMT automation plays a critical role in inspecting, aligning, and ensuring the quality of surface-mounted components. With AI and machine learning, smart vision systems are revolutionizing SMT production lines. For related SMT inspection techniques, see our Technical Processes section.

2. Current State of Vision Technology in SMT

- Automated optical inspection (AOI) is widely used for defect detection.

- High-resolution cameras provide precise component placement verification.

- Vision-guided robotic systems enhance pick-and-place accuracy.

3. AI Integration in Vision Systems

Artificial intelligence enables:

- Pattern recognition for component types and orientations.

- Predictive defect detection and quality control.

- Adaptive learning from historical production data to improve accuracy.

4. Optical and Sensor Advancements

Expand: Advanced Optical Sensors

Recent developments in optical sensors and 3D imaging allow for precise height measurement, solder joint inspection, and real-time error correction. These advancements improve throughput and reduce waste.

5. Benefits of Vision Technology

- Higher accuracy in component placement

- Real-time defect detection

- Reduced labor costs

- Enhanced consistency across production batches

- Improved data collection for process optimization

6. Challenges and Considerations

- High initial investment in AI-enabled vision systems

- Complex integration with existing SMT lines

- Training requirements for operators

- Maintaining calibration and environmental conditions

7. Future Trends

- Integration of AI with real-time analytics for predictive maintenance

- 3D AOI systems with multi-angle inspection

- Vision systems connected to IoT for smart factory applications

- Enhanced machine learning models for defect prediction

8. Conclusion

The future of vision technology in SMT automation lies in intelligent, AI-driven systems that optimize production quality, speed, and efficiency. Staying updated with these advancements ensures a competitive edge in electronic manufacturing. For more on SMT automation, visit our Technical Processes section or Contact Us for consultation.

Contact Us for AI vision technology solutions in SMT automation.

留下评论