Machine vision is rapidly transforming SMT automation — from high-speed inline inspection to AI-powered defect detection and 3D guidance for complex pick-and-place tasks. This article explores current capabilities, emerging trends, implementation best practices, vendor selection tips, and real-world ROI considerations for SMT lines.

Contents

1. Why Vision Technology Matters in SMT

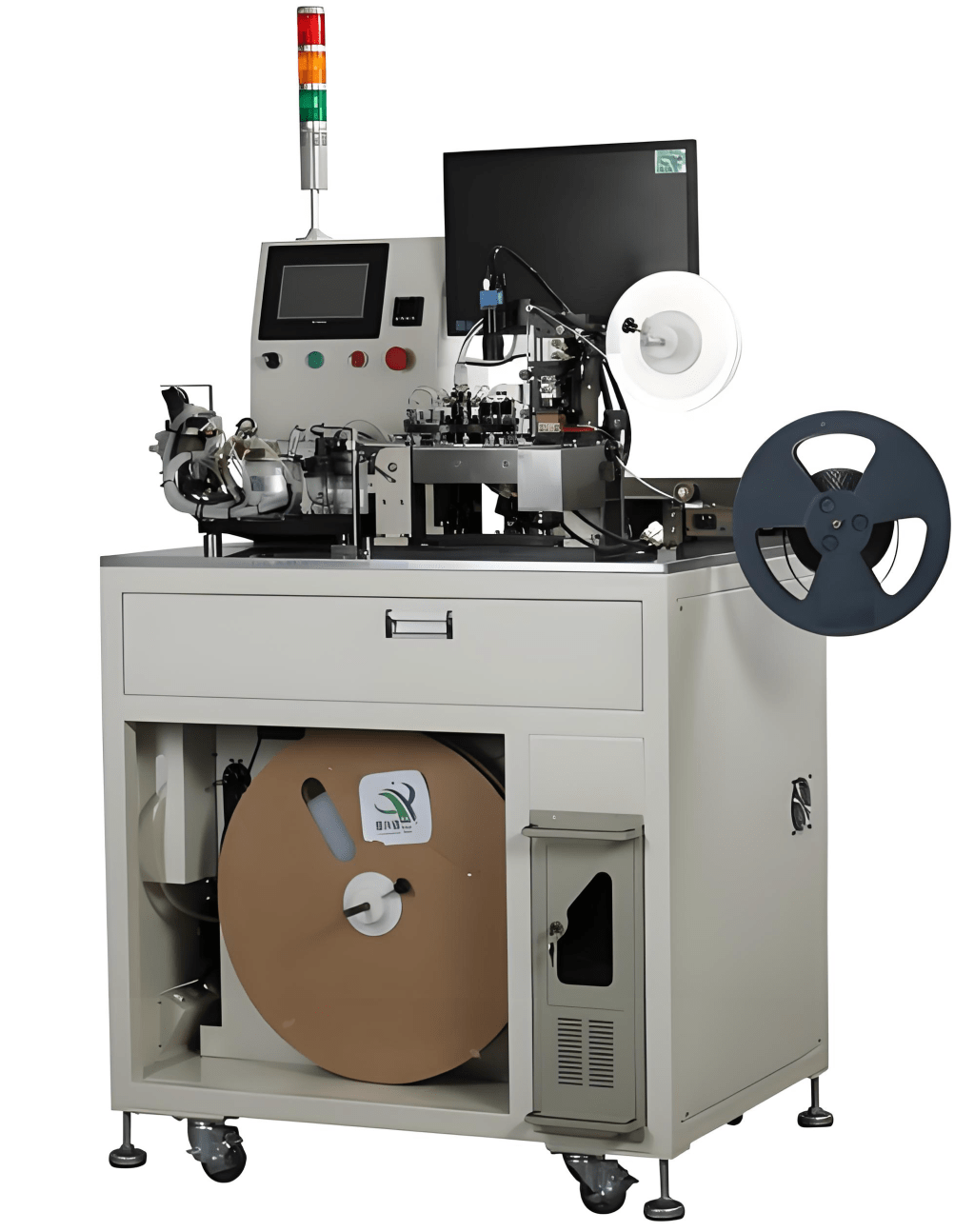

Vision systems enable automated quality control, ensure correct component orientation and presence, reduce manual inspection costs, and increase first-pass yield. Modern SMT lines rely on vision both at assembly (pick-and-place) and packaging stages (taping/tray packing) to catch defects early and prevent rework.

2. Current Capabilities of SMT Vision Systems

2.1 2D Optical Inspection (AOI)

2D AOI inspects solder joints, component presence, and polarity marks at high speed using pattern matching and contrast-based algorithms. It’s a staple for post-reflow inspection and inline process control in most SMT lines.

2.2 3D Vision and Height Measurement

3D vision (laser triangulation, structured light) measures paste volume, component coplanarity, and solder fillet heights — crucial for advanced packages and fine-pitch components.

2.3 AI & Deep Learning for Anomaly Detection

Deep learning models can detect subtle or novel defects that traditional rule-based AOI misses; they also reduce false positives by learning from diverse defect datasets.

3. Emerging Trends Shaping the Future

Click to expand: Key trends

3.1 AI-First Inspection (Self-Learning Models)

Vision systems increasingly incorporate AI models that adapt to new parts and defect types, reducing setup time and extending detection capability across SKUs.

3.2 Edge Computing & Low-Latency Inference

Running vision inference at the edge (on-device) lowers latency and avoids constant cloud round-trips, enabling real-time corrections on high-speed lines.

3.3 3D + Multi-Modal Sensing

Combining 3D, color, IR, and other sensing modalities improves robustness for complex geometries and reflective components.

3.4 Integrated Vision for Taping & Tray Packing

Inline vision at taping/tray stations allows verification before packaging — preventing bad reels/trays from entering inventory and simplifying traceability.

3.5 Predictive Maintenance & Analytics

Vision-based analytics detect wear or alignment drift in feeders and nozzles, feeding predictive maintenance systems to reduce unplanned downtime.

4. Implementation Best Practices

- Define detection objectives: classify defects you must catch vs. those acceptable for downstream rework.

- Collect representative datasets: include variations in lighting, SMT lot-to-lot differences, and process shifts for robust AI models.

- Use modular architectures: separate acquisition, preprocessing, inference, and data logging for maintainability.

- Integrate with MES/WIP: ensure defects and images map to serial/lot IDs for traceability and analytics.

- Plan for lifecycle: model retraining workflows and data governance to keep detection performance high over time.

5. How to Choose a Vision System Vendor

Evaluate vendors on accuracy (detection rate / false positive), ease of integration (APIs, MES connectors), support for 2D/3D modalities, availability of pre-trained models, and on-site demo with your parts and line speed.

6. ROI: Measuring Value of Vision Upgrades

Key metrics: reduction in rework rates, fewer customer returns, labor-hours saved on inspection, reduced scrap, and decreased machine downtime. Pilot small, measure improvements, then scale.

7. Common Challenges & Mitigations

- High false-positive rate → increase representative training data and refine post-processing rules.

- Reflective / transparent parts → use polarization, multiple angles, or 3D sensors.

- Data privacy / storage concerns → keep inference at edge and store metadata instead of full-resolution images where possible.

8. Future Applications to Watch

Vision-guided robotics for complex rework, real-time process control closing the loop with solder paste printers and placement heads, and autonomous line optimization driven by visual analytics.

9. Further Reading & Related SMT PACK LAB Resources

- How to Optimize Taping Efficiency in Low-Volume PCB Production

- Taping Machines & Tray Packers — FAQ & Guide

- SMT Software Solutions (Tag)

- Industry Trends (Tag)

10. Conclusion

Vision technology will continue to be a cornerstone of SMT automation — evolving from rule-based inspection to intelligent, adaptive systems that enable higher yields, lower costs, and smarter production lines. Early adopters who combine robust data pipelines with edge inference and 3D sensing will gain competitive advantages in yield and agility. Need help selecting or integrating vision systems? Contact us

© SMT PACK LAB • For custom taping/tray packing solutions and vision integration, contact us.

留下评论