In SMT (Surface Mount Technology) production, component traceability and correct reel labeling are essential for quality control, inventory management, and assembly efficiency. Improper labeling can lead to assembly errors, wrong component placement, and downtime.

This guide explains the coding and labeling rules for SMD component reels, helping manufacturers, EMS providers, and SMT labs maintain consistency and compliance.

🔹 1. Why Reel Coding and Labeling Is Important

- Component Identification: Ensures the correct component type, value, and tolerance are used.

- Traceability: Tracks manufacturing lot, date code, and supplier for quality audits.

- SMT Assembly Compatibility: Provides pick-and-place machines with readable component data.

- Regulatory Compliance: Follows IPC-7351, JIS, and EIA standards.

🔹 2. Standard Reel Labeling Requirements

A proper SMD reel label typically includes the following information:

| Field | Description | Example |

|---|---|---|

| Manufacturer / Supplier Name | Company producing the component | Panasonic, Samsung |

| Part Number (PN) | Unique identifier of the component | RC0603FR-0710KL |

| Quantity / Reel Count | Number of components on the reel | 5,000 pcs |

| Date Code / Lot Number | Manufacturing batch identifier | 2025-10-25 / L12345 |

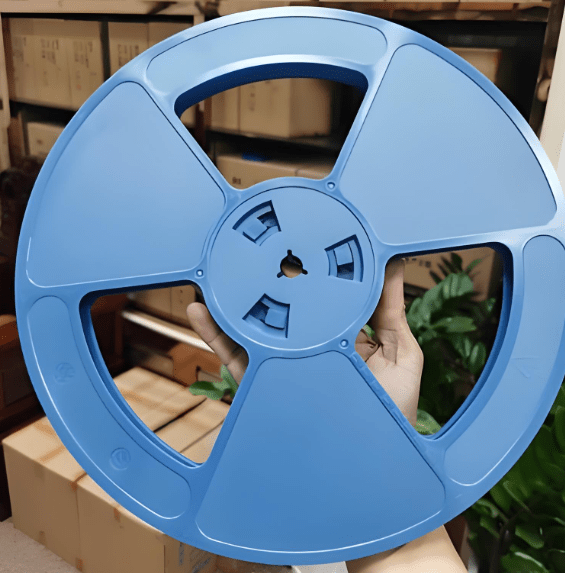

| Packaging Type | Carrier tape width, reel size | 8mm tape / 7” reel |

| RoHS / Compliance Mark | Environmental and safety compliance | RoHS Compliant |

| Orientation / Polarity | Mark for components with polarity | Dot marking for cathode |

| Bar Code / QR Code | Machine-readable information for inventory | Barcode with PN + lot number |

🔹 3. Coding Standards and Rules

3.1 Part Number Format

- Unique code assigned by manufacturer

- Often includes component type, value, tolerance, and packaging code

- Example:

C0603C104K5RACTUC= Capacitor0603= Size codeC104= 100nFK= Tolerance ±10%5RA= Voltage ratingCTU= Packaging and reel code

3.2 Date Code / Lot Number

- Common format:

YYWWorYYYYMMDD - Example:

2510= 25th week of 2025

3.3 Tape and Reel Information

- Carrier tape width: 8mm, 12mm, 16mm, etc.

- Reel size: 7”, 13”, or 15”

- Quantity per reel: Must match the packing data

3.4 Barcodes / QR Codes

- Enables automated inventory management and machine verification

- Typically encodes: PN + Quantity + Date Code + Lot Number

🔹 4. Common Labeling Mistakes

- Missing or illegible part numbers

- Wrong date code or lot number

- No polarity/orientation marking for polarized components

- Barcode not scannable

- Quantity mismatch

Impact: Causes misfeeds, assembly errors, or traceability issues during audits.

🔹 5. Best Practices

- Follow IPC-7351 / JIS standards for labeling

- Use high-contrast printing for readability

- Include both human-readable and machine-readable information

- Double-check orientation and polarity markings for ICs, diodes, and LEDs

- Integrate reel labeling with MES / ERP systems for automated tracking

🔹 6. Conclusion

Proper reel coding and labeling is a critical step in SMT production and supply chain management. Correct labels:

- Reduce assembly errors

- Improve inventory efficiency

- Ensure compliance with international standards

- Enable traceability for quality control and audits

At SMT Pack Lab, we provide fully compliant labeling solutions for SMD reels, integrated with our taping machines and carrier tape systems, ensuring every component is clearly identified, traceable, and ready for automated assembly.

留下评论