Micro-components in SMT assembly, especially miniature SMD components, require precise handling and packaging. Tray packing machines are essential to organize components for pick-and-place machines, reduce handling damage, and maintain high yield. This guide provides a complete, step-by-step approach to selecting the ideal tray packing machine, including technical, operational, and financial considerations.

ContentsIntroduction: Importance of Tray PackingUnderstanding Miniature Component CharacteristicsTypes of Tray Packing MachinesAutomation and Line CompatibilityMaterial Compatibility and HandlingSetup, Operation, and MaintenanceInvestment and Cost AnalysisCommon Issues and TroubleshootingRelated ArticlesIntroduction: Importance of Tray Packing

Tray packing organizes miniature components into standardized trays, ensuring accurate delivery to pick-and-place machines. For low-volume and high-mix production lines, efficient tray packing minimizes human error, reduces machine downtime, and improves yield.

Effective tray packing also facilitates inventory management, batch traceability, and compliance with quality standards, making it critical for both manual and automated SMT operations.Understanding Miniature Component Characteristics

- Size and Pitch: Components may range from 0201 to 0402 packages, requiring delicate handling.

- Shape Variations: Some ICs or passives have arched or irregular surfaces, influencing tray design.

- Moisture Sensitivity: Certain components need ESD-safe and moisture-controlled packaging.

- Weight and Fragility: Lightweight components may shift; heavy or fragile ones need secure slots.

Understanding these characteristics helps in selecting a tray packing machine that maintains stability, orientation, and first-pass yield.Types of Tray Packing Machines

- Manual Tray Packing: Suitable for small batches, but labor-intensive and prone to error.

- Semi-Automatic Tray Packers: Assist operators with alignment and slotting, improving consistency.

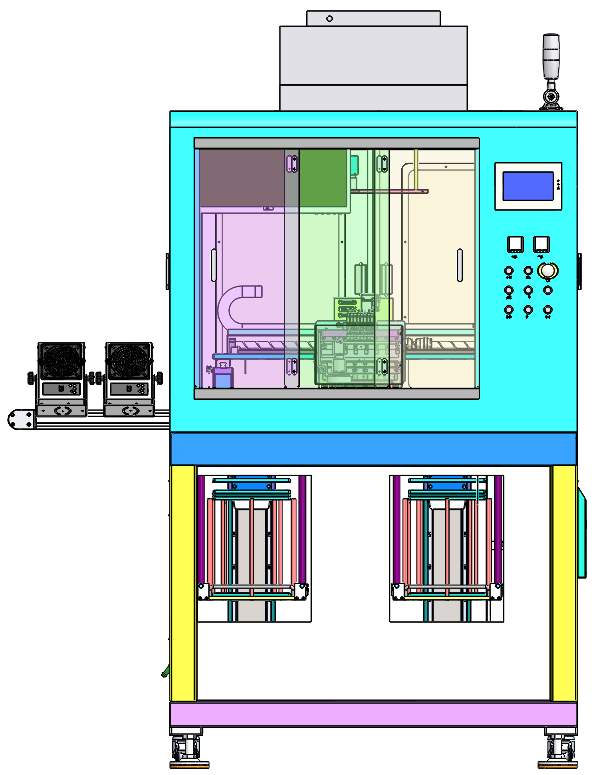

- Fully Automated Tray Packing Machines: High-speed, precise, capable of handling multiple component types with minimal human intervention.

- Flexible Multi-Slot Tray Systems: Adjustable slot sizes and orientations for mixed components, reducing changeover time.

Each type must be evaluated based on production volume, component variety, line integration, and labor availability.Automation and Line Compatibility

Tray packing machines should integrate seamlessly with SMT lines:

- Pick-and-place feeders must accept trays without manual adjustments.

- Automated verification via sensors ensures correct component placement.

- Data exchange with MES systems supports traceability and batch tracking.

- For low-volume production, modular automation allows quick changeovers.

Proper line compatibility reduces bottlenecks and ensures smooth throughput.Material Compatibility and Handling

Tray machines must accommodate:

- Different component sizes, from 0201 resistors to micro ICs

- Varying shapes, including arched, convex, or irregular surfaces

- ESD-sensitive materials and moisture-sensitive components (MSL)

- Multiple tray types: plastic, antistatic, embossed, or custom trays

High-end machines detect component orientation automatically and adjust slots dynamically, ensuring secure placement and high first-pass yield.Setup, Operation, and Maintenance

- Document each setup for recurring production runs

- Calibrate sensors and verify tray alignment before every batch

- Maintain clean trays and machine surfaces to avoid contamination

- Regularly check motors, belts, and feeders for wear

- Train operators on error handling and quick tray changeovers

Following these practices ensures consistent performance and minimizes downtime.Investment and Cost Analysis

Considerations when evaluating cost vs benefit:

- Labor savings from automated vs manual packing

- Flexibility for multi-component and low-volume production

- Maintenance and spare parts availability

- Integration with existing SMT lines and MES

- Long-term ROI based on reduced errors and increased throughput

Common Issues and Troubleshooting

- Component misalignment due to improper tray loading

- Slotting errors from tray deformation or wear

- Sensor misreads due to dust or dirt accumulation

- Changeover delays with mixed component batches

- Integration issues with older pick-and-place machines

Preventive maintenance and operator training are critical to minimize these issues.Related Articles

留下评论