In the world of electronics manufacturing, there exists a unique domain where intangible code meets tangible silicon, where abstract logic intertwines with physical phenomena. The IC programmer stands as a pivotal marker in this domain—not merely a machine on the production line, but a converter, a witness, a magical box that injects a designer’s intent into the material world. Yet, this “magic” is not realized through the machine’s automation alone—it depends on the operator, the human at the boundary of man and machine.

Operation, seemingly a simple word, gains profound depth in the context of IC programming. It is simultaneously the most basic physical action and the most complex cognitive process, simultaneously repetitive labor and creative practice. To truly understand “efficient operation,” one must transcend the instruction manuals and enter a broader reflective space.

Rediscovering Depth in “Operation”: From Mechanical Execution to Systemic Thinking

When we talk about operating an IC programmer, most people imagine standardized motions: placing chips, pressing buttons, checking results. This is correct but superficial. True operation is a multi-layered, multidimensional system.

At the most basic level, operation is indeed a series of physical motions. Yet beneath each movement lies a precise control logic: pressing “start” initiates a chain reaction—power management circuits supply millivolt-level voltage, clock circuits generate timed pulses, DSPs convert binary code into precisely timed electrical impulses.

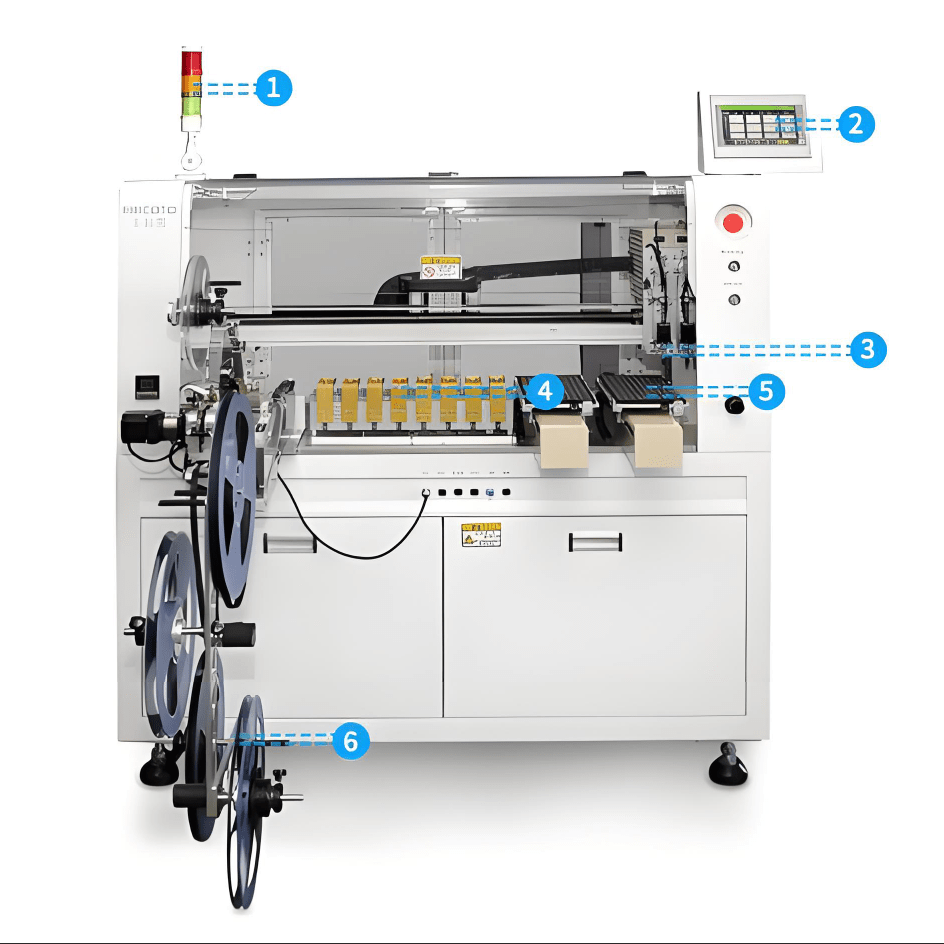

Skilled operators go beyond mere execution. They cultivate an intuitive understanding of equipment states, developed through long-term observation: they know which QFN packages need extra cleaning in high humidity; they can judge contact quality by subtle clicks of a fixture; they even anticipate errors by interpreting the flicker patterns of indicator lights.

This ability transcends skill—it is craftsmanship. Just as a woodworker discerns quality from the sound of a tap, a master IC programmer operator interprets nuanced sensory cues to build a multidimensional understanding of the machine.

At the highest level, operation embodies systemic thinking. Operators perceive not just the device or chip but the entire dynamic production ecosystem. They understand how each action affects downstream processes, recognize how chip characteristics constrain throughput, and foresee long-term consequences of parameter adjustments.

When operators employ this systems perspective, they shift from passive executors to proactive optimizers. For example, rising programming failure rates trigger a systemic investigation: is the power supply stable? Are environmental conditions within spec? Is adapter wear causing intermittent contacts? Does firmware version compatibility matter?

Expanded Perception: Developing Technical Intuition Beyond the Senses

While operation traditionally relies on vision, efficient operation expands sensory perception.

Auditory cues reveal subtle anomalies: relay clicks, fan vibrations, electromagnetic hums—all offer real-time machine health information.

Tactile feedback is critical: the feel of a chip in an adapter, the pressure of a locking mechanism, the subtle resistance during insertion—all inform execution quality.

Integrated perception combines sight, sound, and touch with deep technical understanding, forming an almost instinctual grasp of equipment status. Modern tools enhance this intuition: thermal imaging exposes chip hotspots; precision current probes reveal power dynamics; vibration sensors quantify mechanical health. Skilled operators use these instruments to translate the invisible into measurable insights.

Wisdom in Decision-Making: Balancing Rules and Innovation

Decision-making in high-efficiency operation is far from simple “if-then” logic. It spans multiple layers:

- Rule-based decisions ensure baseline consistency and reliability.

- Pattern-based decisions leverage an internal library of known failure modes to quickly match symptoms with probable causes.

- Principle-based reasoning addresses novel issues using first principles from semiconductor physics, circuit theory, and signal integrity.

Operators seamlessly blend these layers, maintaining reliability while flexibly adapting strategies to production variability. New supplier chips, for instance, may prompt minor parameter optimizations within safe limits before full-scale production.

Execution Precision: Converting Intent into Results

Execution encompasses more than accuracy; it includes timing, force, rhythm, and flow.

- Physical precision ensures proper chip handling, fixture engagement, and sequence adherence.

- Temporal precision aligns human actions with machine cycles, utilizing micro-gaps for preparation, logging, or maintenance.

- Psychological regulation maintains focus, emotional stability, and a flow state, maximizing operational harmony.

Human factors engineering optimizes workstation height, display angle, tool layout, and lighting to minimize strain and maximize comfort, while operators personalize setups for peak performance.

Knowledge Evolution: From Individual Insight to Organizational Capability

Operational knowledge combines explicit, codified knowledge and tacit, experience-based intuition. Efficient IC programming requires a virtuous cycle between the two.

Explicit knowledge—manuals, SOPs, training—is foundational. Tacit knowledge—specialized chip handling, subtle auditory cues, nuanced process adjustments—drives excellence.

Knowledge codification and sharing (via video recordings, data logs, collaborative platforms) transform individual experience into organizational assets. Feedback loops ensure organizational practices inform individual operators, creating a continuous improvement flywheel.

Human-Machine Symbiosis: Redefining Value in an Automated Era

Automation does not replace humans; it liberates them to focus on tasks that machines cannot do.

- Contextual intelligence enables operators to respond to unforeseen scenarios.

- Flexible pattern recognition integrates cross-domain knowledge and intuition.

- Ethical and value-based judgment informs trade-offs between quality, safety, and efficiency.

Optimal symbiosis leverages machines for precision and consistency, humans for oversight, judgment, and innovation. Interfaces must adapt to human needs, presenting complex data in intuitive ways while hiding unnecessary complexity.

Cultivating a Culture of Continuous Improvement

High-efficiency operation requires an ecosystem fostering reflective practice, knowledge sharing, and collaborative problem-solving. Individuals refine their techniques; teams share insights; organizations codify best practices and disseminate them, creating a self-reinforcing loop of continuous operational enhancement.

留下评论