Summary: In modern electronics manufacturing, the quality of system integration for Tape and Reel equipment directly determines the efficiency and reliability of the entire production line. This article explores critical technical questions in the integration process through a detailed Q&A format, covering planning and design, interface protocols, data communication, process coordination, and other core areas. It provides manufacturing enterprises with end-to-end guidance—from equipment selection to system optimization—ensuring smooth project implementation and maximizing operational efficiency.

Table of Contents

Chapter 1: Key Issues in Integration Planning and Design

1.1 What foundational conditions should be evaluated before integrating equipment?

1.2 How to design the optimal equipment layout?

1.3 How to plan project timelines and key milestones?

1.4 How to assess the technical capabilities and experience of an integrator?

1.5 What safety factors need consideration during integration?

Chapter 2: Mechanical and Electrical Integration Challenges

2.1 Standards and compatibility requirements for physical equipment interfaces

2.2 Electrical system integration specifications and safety standards

2.3 Key points for pneumatic system integration and parameter matching

2.4 Vibration control and noise management measures

2.5 Design considerations for maintenance access and operator space

Chapter 3: Data Communication and Control System Integration

3.1 Selection of equipment communication protocols and conversion solutions

3.2 Architecture and implementation of data acquisition systems

3.3 Strategies for integrating real-time control systems

3.4 Establishing equipment monitoring and early warning mechanisms

3.5 Network security and data protection configuration

Chapter 4: Software Systems and MES Integration

4.1 Interface development standards for production management systems

4.2 Integration approaches for recipe management systems

4.3 Data interfacing solutions for quality traceability systems

4.4 Automated report generation and export

4.5 System permission management and operation log recording

Chapter 5: Process Coordination and Quality Control

5.1 Coordinating process parameters with upstream and downstream equipment

5.2 Optimizing material flow systems

5.3 Integration requirements for environmental control systems

5.4 Data consolidation from online inspection systems

5.5 Statistical and analytical systems for quality data

Chapter 6: Testing, Validation, and Performance Assessment

6.1 Standard procedures for equipment integration testing

6.2 Methods for evaluating system performance metrics

6.3 Key points in reliability testing

6.4 Establishing and executing acceptance criteria

6.5 Problem tracking and improvement mechanisms

Chapter 7: Operations, Maintenance, and Continuous Optimization

7.1 Developing preventive maintenance plans

7.2 Strategies for spare parts management

7.3 Personnel training and skill enhancement

7.4 System upgrades and expansion planning

7.5 Efficiency monitoring and optimization measures

Chapter 8: Integration Solutions for Special Applications

8.1 Integration requirements for high-cleanliness environments

8.2 Special configurations for ESD-sensitive environments

8.3 Calibration solutions for high-precision applications

8.4 Integration strategies for flexible manufacturing systems

8.5 Advanced integration for smart factories

Main Content

Chapter 1: Key Issues in Integration Planning and Design

1.1 What foundational conditions should be evaluated before integrating equipment?

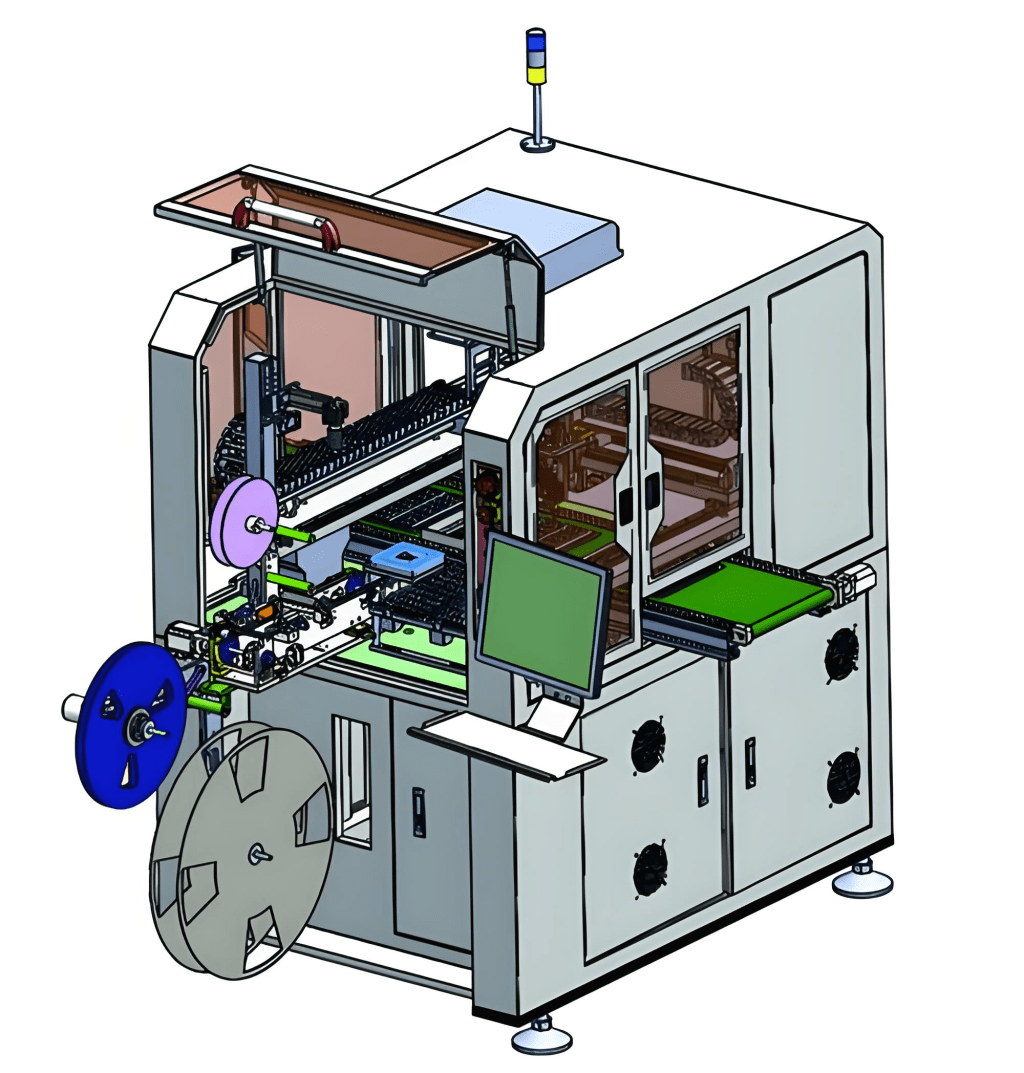

Before initiating a Tape and Reel equipment integration project, it is essential to thoroughly assess existing infrastructure. Start with space analysis by accurately measuring installation area dimensions, including the footprint of the equipment and additional space for maintenance and operation. Typically, allow at least 1.5 meters in front and rear for maintenance and at least 0.8 meters on either side for operator access. Floor load-bearing capacity must also be verified to ensure it can withstand dynamic loads during equipment operation.

Environmental conditions are another critical factor. Record temperature and humidity ranges, assess cleanliness requirements, and measure vibration and noise levels. For precision equipment, maintain temperatures between 20–25°C, humidity at 40–60% RH, and vibration amplitudes below 5 μm. Evaluate the power supply system, including voltage stability, frequency precision, and harmonic content. If necessary, install voltage regulators or UPS systems.

Compatibility with existing production systems is also crucial. Analyze current equipment models, control system architecture, and communication protocols to assess compatibility with new devices. Examine material handling systems, including supply methods, transfer speeds, and buffer capacities. Comprehensive evaluation at this stage provides accurate data for subsequent integration design.

1.2 How to design the optimal equipment layout?

Optimal layout design should consider production workflow, material flow paths, operator efficiency, and future scalability. Value stream analysis can help determine the best position of equipment on the line, often favoring U-shaped or L-shaped layouts to minimize material transport distances and maximize space utilization. Equipment spacing should consider safety, maintenance, and material handling requirements—typically 1.2–1.5 meters between units.

Material flow paths should follow a unidirectional principle to avoid crossovers and backtracking. Raw material inlets and finished product outlets must align with upstream and downstream equipment, with buffer zones sized appropriately. For systems using AGVs or conveyors, clearly define material transport channels and install necessary safety barriers.

Operator zones should follow ergonomic principles, allowing staff to comfortably perform equipment operations, quality inspections, and maintenance. Control panels and displays should be mounted 1.4–1.6 meters above the floor, with emergency stops easily accessible. Allocate space for training and documentation storage as well.

1.3 How to plan project timelines and key milestones?

A typical Tape and Reel integration project lasts 12–16 weeks, depending on equipment complexity, integration depth, and site conditions. It can be divided into five phases: planning and design (2–3 weeks), equipment modification (3–4 weeks), on-site installation (2 weeks), system commissioning (3–4 weeks), and acceptance and delivery (1–2 weeks).

- Planning & Design: Develop detailed technical designs, confirm interface protocols, and create project schedules. Conduct multiple coordination meetings to ensure alignment.

- Equipment Modification: Perform interface modifications, upgrade control systems, and adjust mechanical structures at the supplier’s facility.

- On-Site Installation: Position equipment, connect utilities, and perform preliminary testing while coordinating with the integrator and client.

- Commissioning: Conduct single-machine and line-wide tests, followed by system optimization.

- Acceptance & Delivery: Verify performance, deliver documentation, and provide personnel training.

Establish clear acceptance criteria and quality checkpoints for each phase. Use project management software to track progress and regularly review milestones to identify and resolve issues.

1.4 How to assess the technical capabilities and experience of an integrator?

Assessing an integrator’s capabilities requires a multi-dimensional approach. Review industry experience, project scale, and technical complexity, emphasizing similar equipment integration cases. Request detailed project records and conduct on-site inspections.

Evaluate the technical team’s experience, qualifications, and certifications. Competent integrators typically demonstrate multi-disciplinary expertise in mechanical, electrical, software, and control systems. Assess R&D capabilities, including proprietary solutions, patents, and software IP.

Project management competency impacts implementation. Examine methodologies, quality control systems, and risk management procedures. Review detailed project plans covering scheduling, resource allocation, quality checks, and contingency measures. Post-sales service and support, including response times and spare parts availability, are also critical.

1.5 What safety factors need consideration during integration?

Safety considerations include mechanical, electrical, software, and environmental aspects:

- Mechanical: Install protective guards on moving parts, sufficient emergency stops, and safety light curtains/door locks. Ensure proper anchoring for heavy equipment.

- Electrical: Follow grounding, leakage, overload, and short-circuit protection standards. Control circuits should use low-voltage systems; high-voltage components must be isolated. Cabinets should meet IP54 or higher.

- Software: Implement tiered access controls; critical parameter changes require authorization and logging. Maintain robust data backup and recovery.

- Environmental: Control noise below 75 dB, manage heat dissipation, and handle waste per environmental regulations. Provide clear emergency egress routes.

Conclusion

Summary and Outlook

A successful Tape and Reel equipment integration requires advanced technical solutions, structured planning, and strict process control. From initial design to operational optimization, every stage demands professional expertise.

With Industry 4.0 and smart manufacturing, integration will evolve toward intelligence, flexibility, and digitalization. Future solutions will leverage data analytics and AI for autonomous optimization and predictive maintenance. Modular and standardized approaches will further enhance integration efficiency and quality.

For manufacturers, establishing a systematic integration management framework, developing skilled technical teams, and selecting the right partners are critical for successful projects. Scientific methods and advanced technologies ensure that Tape and Reel equipment system integration supports the transformation and upgrading of the electronics manufacturing industry.

References

[Per academic standards, list relevant technical standards, scholarly papers, and professional books with author, title, publisher, and year details.]

留下评论