IC programmers are critical for reliable SMT production, but even experienced operators encounter unexpected issues. This guide covers frequent problems and step-by-step solutions, including hardware, firmware, interface, and communication troubleshooting, ensuring minimal downtime and maximum yield.

Common IC programmer issues and how to resolve them

Table of Contents

- Introduction

- Common Issues Overview

- Firmware and Hardware Solutions

- Communication and Interface Errors

- Maintenance and Daily Checks

- SOP and Training Guidelines

- Conclusion

Introduction

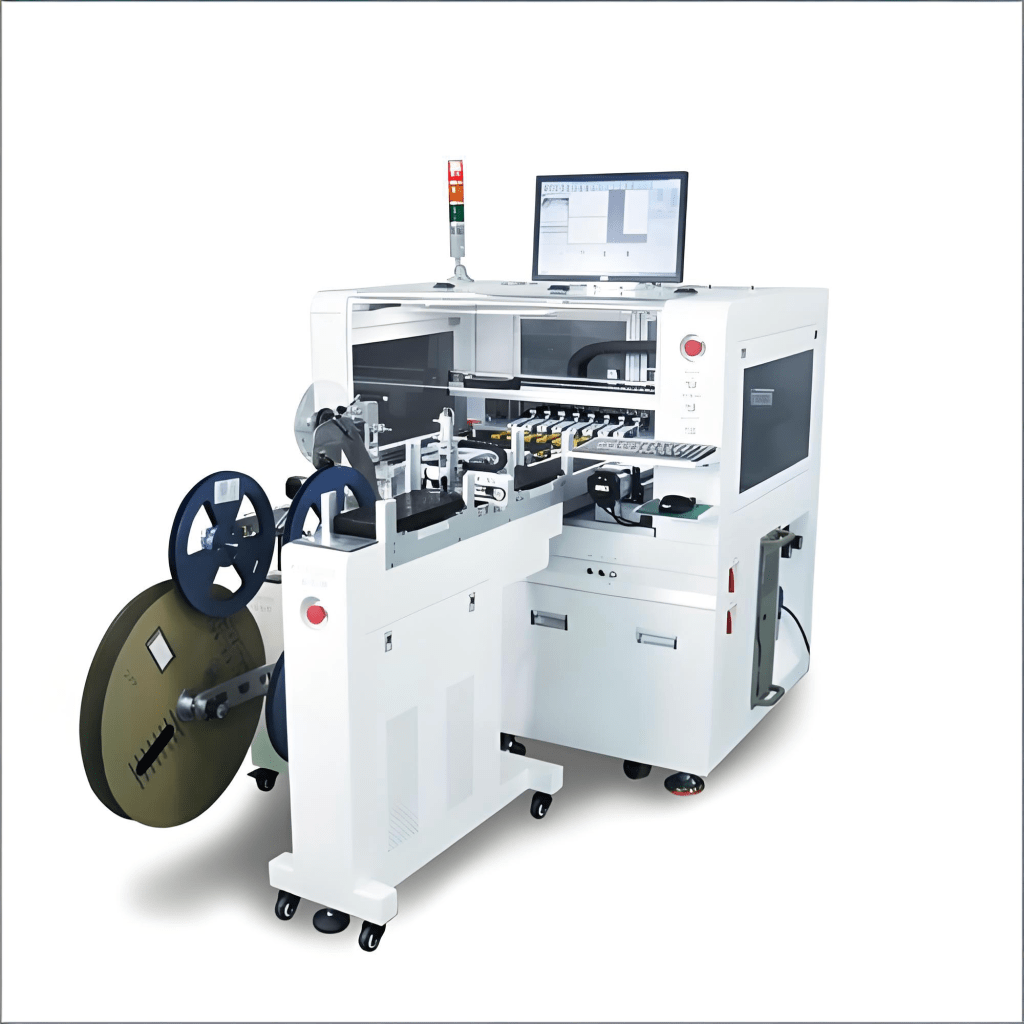

IC programmers are used for high-speed chip programming on SMT lines, and their reliability directly impacts production yield. Operators often face issues ranging from firmware mismatches, socket problems, communication failures, to unexpected error messages. Understanding the root causes and applying systematic troubleshooting ensures smooth operations.

Common Issues Overview

Timeout and Programming Failures

Frequent timeout errors often result from misaligned ICs, dirty contacts, or incorrect fixture placement. Always verify socket condition and ensure the IC is seated properly. Adjust timeout settings if programming multiple devices in batch mode. Checksum and Data Verification Errors

Checksum mismatches usually indicate firmware conflicts or corrupted data. Re-verify the programming file, reload firmware, and check cable connections to avoid repeated errors. Physical Socket and Pin Issues

Bent, worn, or dirty pins cause intermittent failures. Inspect sockets regularly, clean contacts with isopropyl alcohol, and replace damaged pins promptly to maintain consistent performance.

Firmware and Hardware Solutions

Firmware Updates and Compatibility

Keep programmer firmware updated to the latest approved version. Check release notes for compatibility with IC types and SMT line software. Avoid unauthorized firmware updates as they may introduce unexpected behavior. Hardware Inspections

Examine all connectors, power supplies, and PCB assemblies. Ensure the unit is free from dust and moisture. Verify in-line programming system connections and replace worn components proactively.

Communication and Interface Errors

Serial Port and USB Issues

Check COM port settings, cable integrity, and USB hub connections. Use built-in diagnostic tools to monitor data transmission and latency, especially when programming multiple devices simultaneously. Network and Multi-Device Communication

Verify network stability if using LAN-connected IC programmers. Ensure each device has a unique address and proper protocol configuration. Monitor packet loss and error rates to prevent programming interruptions.

Maintenance and Daily Checks

- Daily visual inspections of sockets, pins, and cables.

- Clean contacts and fixture surfaces with approved cleaning agents.

- Log all minor issues and resolutions for reference.

- Check firmware and software status weekly.

- Perform test programming on reference ICs to verify accuracy.

SOP and Training Guidelines

Operators should follow structured SOPs covering daily, weekly, and monthly maintenance routines. Provide training on troubleshooting common errors, ESD protection, and MES integration. Internal links: More IC Programmer Guides.

Conclusion

Systematic troubleshooting of IC programmer issues—including firmware, hardware, communication, and operational checks—ensures consistent SMT line performance. By implementing preventive maintenance, structured SOPs, and operator training, production yield improves while minimizing unexpected downtime.

Author: SMT PACK LAB Technical Team · Updated: 2025-11-07

留下评论