1. Introduction

Tray loaders are essential components in SMT end-line manufacturing, responsible for moving trays efficiently between workstations. Despite their importance, they can encounter various issues that disrupt production, reduce yield, or cause downtime. Understanding common problems and their solutions is critical for maintaining smooth line operations.

Table of Contents

- 1. Introduction

- 2. Common Tray Loader Issues

- 3. Mechanical Problems and Solutions

- 4. Pneumatic and Hydraulic Issues

- 5. Control System and Software Issues

- 6. Operator-Related Issues

- 7. Preventive Maintenance and Best Practices

- 8. Case Studies

- 9. MES Integration and Logging

- 10. Conclusion and Further Resources

2. Common Tray Loader Issues

- Tray misalignment causing pick-and-place errors.

- Trays jamming or colliding with downstream equipment.

- Sensor failures or misreads.

- Pneumatic or hydraulic delays affecting speed.

- Servo motor or encoder errors.

- Operator mistakes or mishandling.

3. Mechanical Problems and Solutions

3.1 Worn Rails and Guide Issues

Trays may misalign due to worn guide rails. Regular inspection and lubrication can reduce friction and prevent misplacement.

3.2 Tray Locking and Springs

Deformed trays or weak springs can cause misfeeds. Replace damaged trays and check spring tension periodically.

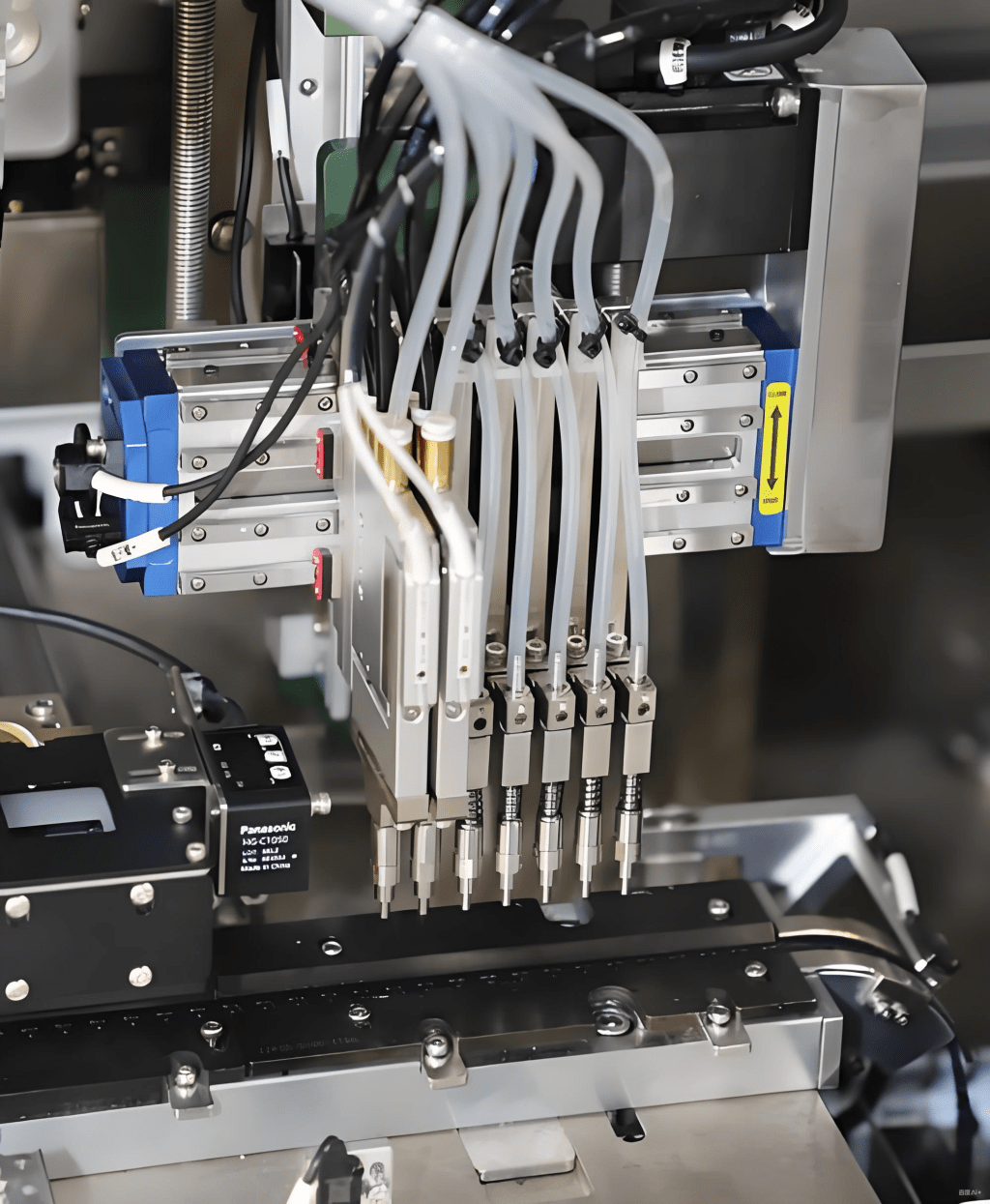

3.3 Actuator and Slide Wear

Sliders and actuators may wear over time. Maintain lubrication schedules and replace worn rods to ensure smooth motion.

4. Pneumatic and Hydraulic Issues

- Inconsistent air pressure can delay tray movement.

- Leaky or clogged pneumatic components reduce performance.

- Hydraulic or pneumatic timing mismatch causes collisions.

Solutions include checking air pressure daily, replacing worn seals, and validating cylinder strokes.

5. Control System and Software Issues

5.1 Servo and Encoder Errors

Incorrect servo parameters or encoder misreads may disrupt synchronization. Regular calibration and monitoring are recommended.

5.2 PLC Logic Problems

PLC timing errors or communication delays can lead to misfeeds. Adjust logic sequences and check sensor signals.

5.3 Software Integration Challenges

MES and line software misconfigurations may prevent smooth operation. Ensure consistent updates and verify integration points.

6. Operator-Related Issues

- Incorrect tray placement or handling.

- Failure to follow standard operating procedures (SOPs).

- Neglecting routine maintenance checks.

Proper operator training and clear SOP documentation are essential for avoiding human error.

7. Preventive Maintenance and Best Practices

- Daily: Air pressure, sensor, and tray lock inspections.

- Weekly: Clean guides, lubricate sliders, check for mechanical wear.

- Monthly: Validate servo parameters, encoder feedback, and PLC logic.

- Quarterly: Replace worn components and perform full calibration.

8. Case Studies

Case Study 1: Jam at Feeder Entry

Problem: Tray jammed due to misalignment at feeder input. Solution: Adjust guide rails, check tray springs, and verify PLC timing.

Case Study 2: Misread Sensor Causing Line Stop

Problem: Sensor misread stopped the line. Solution: Replace faulty sensor and adjust sensor alignment.

Case Study 3: Servo Delay Leading to Collision

Problem: Servo motor delayed tray movement, causing collision. Solution: Re-tune servo parameters and monitor encoder feedback.

9. MES Integration and Logging

- Track tray movements and line stoppages in real-time.

- Receive alerts for misalignment or sensor failure.

- Analyze logs to predict maintenance needs and prevent downtime.

10. Conclusion and Further Resources

Understanding common tray loader issues and implementing preventive measures ensures smooth SMT production. Combining mechanical, pneumatic, control, and operator solutions improves line efficiency and reduces downtime.

Further resources:

留下评论