Chapter 1: Core Decision Framework for Labeling System Selection

1.1 The Strategic Nature of System Selection: Beyond Equipment Procurement

The process of selecting a labeling system transcends mere equipment acquisition; it represents a strategic investment in core manufacturing capabilities. This decision profoundly impacts production line flexibility, product quality consistency, and long-term operational cost structures. A well-founded selection must be grounded in comprehensive analysis of both current operational requirements and future business objectives.

Critical Evaluation Dimensions:

- Alignment between existing production methodologies and projected capacity requirements

- Correlation between quality assurance protocols and labeling precision specifications

- Equilibrium between operator technical proficiency and system complexity

- Integration requirements with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) systems

1.2 Development of Comprehensive Evaluation Metrics

Prior to initiating the selection process, organizations must establish a robust evaluation framework incorporating both quantitative and qualitative assessment criteria across multiple dimensions.

Technical Performance Parameters:

- Dimensional accuracy: Targeting precision ranges between ±0.1mm to ±0.5mm

- Operational throughput: Differentiating between peak theoretical capacity and sustainable production rates

- Changeover efficiency: Measuring mean and maximum product transition durations

- System reliability: Evaluating Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) metrics

Economic Viability Indicators:

- Total capital expenditure: Incorporating equipment acquisition, implementation, and training costs

- Unit cost analysis: Comprehensive calculation including consumables, energy consumption, and labor

- Return on investment: Quantifying efficiency gains and quality improvement benefits

- Lifecycle cost modeling: Total cost of ownership projections across 5-8 year operational horizons

Operational Integration Factors:

- Workforce development requirements and training complexity

- Compatibility with existing facility infrastructure and layout

- Interoperability with upstream and downstream production equipment

- Maintenance resource planning and technical support requirements

Chapter 2: Comprehensive Analysis of Automated Labeling Systems

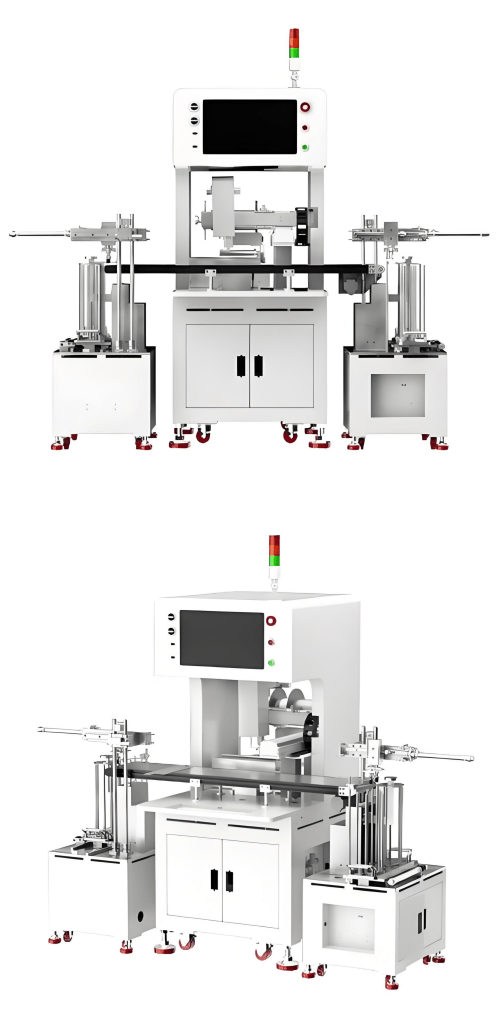

2.1 Architectural Framework and Core Subsystems

Automated labeling systems represent sophisticated technological ecosystems whose primary value proposition lies in achieving unmanned high-precision, high-volume labeling operations. Understanding system architecture is fundamental to informed decision-making.

Control System Architecture:

Contemporary automated systems employ distributed control paradigms. Primary Programmable Logic Controllers (PLCs) coordinate overall system operation, while dedicated motion controllers manage precise labeling kinematics, and machine vision systems conduct autonomous quality verification. This architectural approach ensures operational resilience and rapid response capabilities.

Advanced implementations utilizing Siemens S7-1500 series PLCs, integrated with servo drive technology and high-resolution encoders, can achieve millisecond-level response characteristics. State-of-the-art systems incorporate Industrial Internet of Things (IIoT) gateways to enable real-time performance monitoring and remote diagnostics.

Sensor System Configuration Methodology:

Sensor selection and deployment strategies directly determine system adaptability. While fundamental photoelectric sensors facilitate product detection, complex operational environments necessitate specialized sensor arrays:

- Registration mark sensors: Enable label positioning with 0.1mm accuracy

- Ultrasonic detection systems: Identify transparent substrates and specialized materials

- Machine vision arrays: Execute complex pattern recognition and quality validation

- Proximity measurement systems: Maintain optimal standoff distances between application heads and product surfaces

Actuation System Technological Progression:

The evolution from basic pneumatic actuation to sophisticated electromechanical servo control has continuously enhanced precision and velocity characteristics. Emerging technological trends favor direct-drive motor implementations, eliminating mechanical transmission backlash and achieving positioning accuracies approaching ±0.05mm.

2.2 Operational Performance Validation

Equipment specifications provided by vendors typically reflect ideal laboratory conditions. Real-world production environments introduce numerous variables requiring thorough evaluation.

Sustainable Throughput Analysis:

Published maximum rates (e.g., 150 applications/minute) represent theoretical limits. Practical operational considerations including product spacing, label complexity, and quality verification requirements typically result in sustainable production rates 15-25% below theoretical maximums.

Long-Term Precision Stability:

Accuracy specifications represent dynamic rather than static performance indicators. Mechanical wear, thermal expansion, and component aging introduce temporal performance variations. Premium systems incorporate automatic compensation algorithms to maintain precision stability, a critical evaluation criterion during selection processes.

Environmental Adaptation Verification:

Ambient conditions including temperature fluctuations, humidity variations, mechanical vibration, and electromagnetic interference significantly impact system performance. Comprehensive environmental testing during the evaluation phase is essential, particularly for specialized industries including electronics manufacturing and food processing.

Chapter 3: Semi-Automatic System Implementation Considerations

3.1 Human-Machine Interface Optimization

Semi-automatic systems derive their primary value proposition from optimized human-machine collaboration. Superior system design enables operators to focus on value-added decision-making while automation handles repetitive precision tasks.

Ergonomic Design Principles:

Workstation configuration must incorporate comprehensive ergonomic analysis, including:

- Operational elevation optimization based on anthropometric data

- Material flow path engineering for minimal handling

- Visual interface design to reduce cognitive loading

- Work cycle timing aligned with natural human rhythms

Skill Requirement Mitigation Strategies:

Intelligent assistive functionalities reduce operator technical requirements through:

- Error prevention mechanisms utilizing sensor-based verification

- Guided operational sequences via interactive displays

- Adaptive parameter adjustment for product variations

- Predictive maintenance alerts and consumable monitoring

3.2 Flexibility Implementation Frameworks

The principal advantage of semi-automatic systems lies in operational flexibility, achieved through deliberate technical implementation.

Rapid Changeover Methodologies:

- Mechanical quick-change systems utilizing kinematic coupling principles

- Parameter profile management for instantaneous product changeovers

- Machine learning algorithms for operational parameter optimization

- Standardized interface architecture for modular component integration

Adaptation Range Engineering:

System versatility is enhanced through:

- Tool-less mechanical adjustment capabilities

- Software-based error compensation algorithms

- Self-optimizing control parameters

- Scalable architecture supporting future capability expansion

Chapter 4: Comprehensive Cost Analysis Methodology

4.1 Capital Investment Composition

Equipment acquisition cost represents only one component of total investment. Complete financial analysis must encompass all associated expenditures.

Direct Capital Requirements:

- Equipment procurement cost

- System implementation and commissioning

- Initial spare parts inventory

- Operator training programs

- Foundational consumable inventory

Indirect Implementation Costs:

- Infrastructure modification expenses

- Production interruption impacts

- Learning curve efficiency reductions

- System integration development resources

4.2 Operational Expenditure Modeling

Operating costs demonstrate dynamic characteristics requiring sophisticated modeling approaches.

Consumable Cost Analysis:

Label material economics extend beyond purchase price to include:

- Inventory carrying costs and capital allocation

- Process waste rates during normal operation

- Equipment-specific material compatibility requirements

- Changeover-related material attrition

Energy Efficiency Comparative Analysis:

Significant energy consumption variations exist between technological approaches:

- Servo versus pneumatic system energy differentials (30-50%)

- Thermal management system efficiency characteristics

- Standby power consumption profiles

- Power factor correction requirements

Maintenance Cost Forecasting:

Predictive maintenance modeling based on equipment characteristics:

- Critical component service life expectations

- Specialized tooling and test equipment requirements

- Technical support service level agreements

- Software upgrade policies and associated costs

Chapter 5: Technical Integration Considerations

5.1 Data Integration Capability Assessment

In contemporary smart manufacturing environments, labeling systems function not only as production equipment but also as critical data acquisition nodes.

Interface Capability Verification:

- Industrial communication protocol support (PROFINET, Ethernet/IP, Modbus TCP)

- Real-time data exchange performance characteristics

- System integration depth from monitoring to control functionality

- Cybersecurity protocols and access control mechanisms

Information Modeling Standards Compliance:

- OPC UA information model completeness

- Equipment description file standardization

- Data point organization and access efficiency

- Manufacturing system data mapping integrity

5.2 Production System Synchronization

Labeling systems require deep integration with production line ecosystems.

Temporal Synchronization Requirements:

- Conveyor velocity synchronization precision

- Process sequencing with adjacent manufacturing operations

- Exception handling coordination protocols

- System recovery synchronization capabilities

Quality Management Integration:

- Machine vision system data correlation

- Gravimetric verification feedback loops

- Process parameter adaptive control

- Real-time quality traceability systems

Chapter 6: Supplier Evaluation Framework

6.1 Technical Capability Assessment

Supplier technological competence determines long-term system performance.

Research and Development Capability:

- Engineering team qualifications and industry experience

- Core technology proprietary development ratios

- Technology iteration velocity and quality

- Intellectual property portfolio and technical barriers

Implementation Methodology:

- Requirements analysis techniques and tools

- System design standards and documentation

- Commissioning process rigor and completeness

- Knowledge transfer effectiveness

6.2 Service Delivery Capability Evaluation

Long-term operational success depends on supplier support capabilities.

Technical Support Infrastructure:

- Service network geographical coverage

- Support personnel technical qualifications

- Spare parts inventory strategy

- Remote support technological capabilities

Continuous Improvement Mechanisms:

- Customer feedback collection and processing

- Product enhancement decision processes

- Software update distribution strategies

- Technical education program quality

Chapter 7: Implementation Process Excellence

7.1 Requirements Engineering Execution

Precise requirement definition forms the foundation for successful implementation.

Requirements Elicitation Techniques:

- Process observation and value stream analysis

- Stakeholder requirement workshops

- Prototype system validation testing

- Requirement prioritization methodology

Requirements Specification Quality:

- Functional requirement completeness

- Performance metric quantification

- Interface specification technical detail

- Acceptance criteria objectivity

7.2 Project Management Discipline

Implementation success requires professional project management practices.

Risk Management Systematic Approach:

- Technical risk identification and mitigation

- Schedule risk monitoring and adjustment

- Quality risk prevention and control

- Communication risk management

Knowledge Management Integrity:

- Technical documentation architecture

- Operational training program design

- Maintenance knowledge transfer

- Problem-solving experience capture

Chapter 8: Strategic Development Considerations

8.1 Technology Evolution Planning

Selection criteria must address both current requirements and future technological directions.

Technology Trajectory Analysis:

- Drive technology evolution toward servoelectric and direct-drive solutions

- Control system migration to edge computing and cloud deployment

- Sensing technology advancement toward vision systems and AI

- Software technology development toward platform solutions

Upgrade and Expansion Architecture:

- Hardware modularization principles

- Software architecture openness

- Interface standard future-proofing

- Performance specification headroom

8.2 Organizational Capability Development

Equipment performance realization depends on organizational competency development.

Talent Management Strategy:

- Operator skill certification standards

- Maintenance technician competency requirements

- Management capability frameworks

- Training system continuous improvement

Process Optimization Methodology:

- Equipment management standardized processes

- Quality control improvement mechanisms

- Cost management refinement

- Continuous improvement cultural development

Through systematic analysis across these eight strategic dimensions, organizations can not only select appropriate labeling technology but also establish continuously improving production capabilities. This rigorous approach demands specialized knowledge, methodological discipline, and strategic perspective, but delivers sustainable competitive advantage through operational excellence and quality consistency.

留下评论