Summary: The true value of a tape and reel machine is realized only when it runs continuously and reliably. Proper installation and scientific maintenance are the foundation for ensuring the machine reaches its design lifespan and achieves maximum ROI. This FAQ acts as your chief engineer, offering over 10,000 words of in-depth guidance covering site preparation, daily maintenance, advanced diagnostics, and lifecycle management, helping you build rock-solid production capabilities.

Part 1: Precision Installation – Laying the Foundation for a Decade of Stable Operation

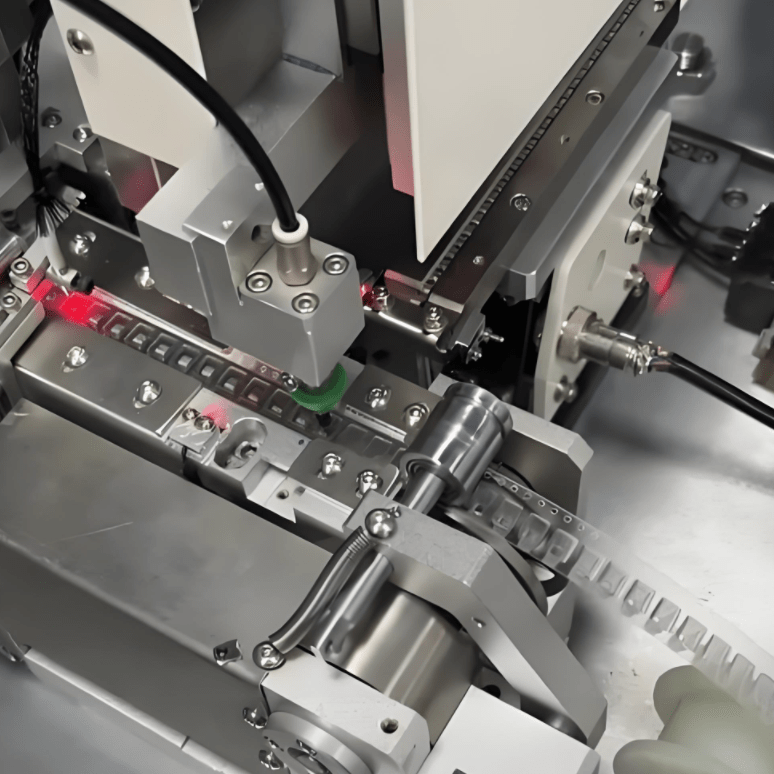

Installation is not simply “plug and play”; it is a detailed system engineering process. Improper installation can lead to persistent performance issues, high failure rates, and shortened equipment lifespan.

Q1: What key site preparations are required before the machine arrives?

Answer: Comprehensive site preparation is the first step for successful installation, covering several critical dimensions:

1. Environmental Control:

- Temperature & Humidity: Maintain 20°C–25°C and 40%–60% relative humidity. Temperature fluctuations can affect mechanical components; high humidity risks ESD and component oxidation, low humidity increases static buildup.

- Cleanliness: As a precision device, dust and debris can contaminate rails, nozzles, camera lenses, and light sources, causing jams, vision errors, and wear. Site should meet ISO Class 8 (100,000) or higher, separated from corrosive chemicals and oil mist.

- ESD Protection: Anti-static flooring and grounded wrist straps for operators; equipment grounding must be reliable.

2. Infrastructure & Utilities:

- Power:

- Stability: Provide clean and stable electricity. Recommended: online UPS and voltage stabilizer to protect sensitive controllers and servo drives.

- Specification: Typically 220VAC (±10%), 50/60Hz, single/three-phase. Ensure sufficient socket capacity and proper grounding.

- Dedicated Circuit: Avoid sharing with high-power machines to reduce interference.

- Compressed Air:

- Quality & Pressure: Supply dry, clean, oil-free air at 0.5–0.7 MPa.

- Treatment: Install a three-stage filter system: coarse filter (water/oil), precision filter (micron particles), and refrigerated/adsorption dryer. Water or oil can corrode valves and block vacuum generators, causing catastrophic issues.

- Floor & Space:

- Load & Level: Floor must meet load requirements; level machine using a precision level (≥0.02mm/m). Uneven floors cause stress, noise, wear, and precision loss.

- Operation & Maintenance Space: Leave adequate clearance: Front/Back ≥1.5m, Sides ≥1m.

Q2: What are the steps and precautions for unpacking and initial inspection?

Answer: Careful and documented handling is critical:

- Document Check: Verify shipping list and purchase order; inspect for damage, water ingress; take photos.

- Systematic Unpacking: Follow indicated order, preserve packaging for at least one week.

- Contents Verification: Check main unit, spare parts, tools, cables, manuals, software.

- Visual Inspection: Examine mechanical components for scratches, dents, cracks, or looseness; report any anomalies.

Q3: What is the precise workflow for positioning and mechanical installation?

Answer: Goal is to secure the machine accurately and stably:

- Movement & Positioning: Use forklift; place wooden blocks under base; avoid lifting or pushing non-load-bearing parts.

- Precision Leveling:

- Measure X and Y axes with a high-precision level.

- Adjust leveling feet to ensure ≤0.05mm/m deviation.

- Importance: Leveling ensures axis parallelism and verticality; unlevel machines wear faster.

- Module Installation: Install vibratory feeders, tape feeders, take-up reels; tighten screws to specified torque.

- Air Line Connections: Use Loctite 565 or quality PTFE tape; ensure no debris enters fittings.

Q4: Core technical specifications for electrical and pneumatic connections?

Answer: Safety and compliance are critical:

- Electrical:

- Connect L, N, PE correctly; grounding must be absolutely reliable.

- Connect monitors, peripherals, and network cables; ensure shielded cables.

- Pneumatic:

- Connect from three-stage filter outlet.

- Purge lines before applying pressure.

- Check pressure gauges; inspect joints with soapy water for leaks.

Q5: Steps for first power-up, software installation, and system calibration?

Answer: Activate machine and prepare for operation:

- First Power-On & Self-Test: Observe startup for abnormal noises; axes should return to origin smoothly.

- Software Installation: Install control software, drivers, enter license.

- System Calibration (Supplier-guided):

- Vision calibration: Pixel accuracy.

- Pick-and-place calibration: Nozzle vs. camera alignment.

- Tape step & clamp calibration: Pocket accuracy.

- Vacuum & air calibration: Ensure pick-up force and air blow are correct.

Q6: How to perform installation acceptance testing?

Answer: IQ (Installation Qualification) confirms installation:

- No-load test: Run at 50%, 80%, 100% speed for 30+ minutes; check smooth motion and vibration.

- Load test & capability (Cpk): Test representative components, measure placement deviation, target Cpk ≥1.67, verify UPH, vision detection accuracy.

- Documentation & Training: Receive acceptance report, record all calibration; ensure operators complete basic training.

Part 2: Scientific Maintenance – Building a Zero-Downtime Defense System

Maintenance is prevention, not repair. A strong system eliminates problems at the root.

Q7: How to establish a comprehensive, executable preventive maintenance system?

Answer: Combine time-based and usage-based schedules:

- Daily (5–10 min):

- Check air & vacuum pressures, listen for abnormal sounds, clean residual material, wipe lenses with ≥95% ethanol, inspect nozzles.

- Weekly (30 min):

- Clean feeder tracks, check nozzle wear, check guide rollers and sensors, lightly lubricate small cylinders.

- Monthly (2–4 hrs):

- Deep clean, inspect belts and linear guides, lubricate with lithium grease (small amounts, avoid dust accumulation), run test programs.

- Quarterly/Annually:

- Full calibration, check servo brushes, pneumatic valves, vacuum filters; replace as needed.

Q8: Common failure modes and systematic troubleshooting?

Answer: Follow “simple to complex, outside to inside” logic:

- High reject rate: Check if vision detection or pick-and-place issue.

- Vision: lens, lighting, thresholds, component variability.

- Pick-and-place: vacuum (-60kPa+), nozzle blockages, blow valves, Z-axis alignment, tape pocket position.

- Tape packaging issues: Check heat seal temperature, pressure, time, tape material, guide wheels.

- Excessive noise/vibration: Identify source (feeder, axes, take-up reel), check lubrication, coupling, motor parameters.

- Communication/software faults: Restart software, check cables, consult logs.

Q9: How to manage spare parts for cost-efficiency?

Answer: Use ABC classification:

- A (critical, high-value): Servo motors, PLCs, high-res cameras; maintain 1 set or emergency agreement.

- B (medium-value): Feeder surfaces, nozzle sets, guides, heat modules; maintain 1–2 sets.

- C (consumables): Nozzles, hoses, filters, fuses; bulk purchase, high inventory.

Maintain a spare parts log with model, specs, location, minimum stock, supplier.

Q10: How to elevate maintenance to predictive level using data & advanced tech?

Answer: Move from traditional to intelligent maintenance:

- Data tracking: MTBF, MTTR, trend charts for reject rate, UPH, servo current, vacuum.

- Predictive tech:

- Vibration analysis on motors and bearings.

- Thermal imaging for hot spots in cabinets and drives.

- IoT platform: Real-time data collection, AI-based health modeling, auto work orders, approaching zero unexpected downtime.

Conclusion

Tape and reel machine installation and maintenance is a multidisciplinary field combining mechanical engineering, electrical automation, data science, and supply chain management. Treat installation as a precision surgical procedure, maintenance as ongoing health management guided by data. Only by doing so can you maximize the value of this automated asset, ensuring decade-long reliability as your production efficiency and quality guardian.

留下评论