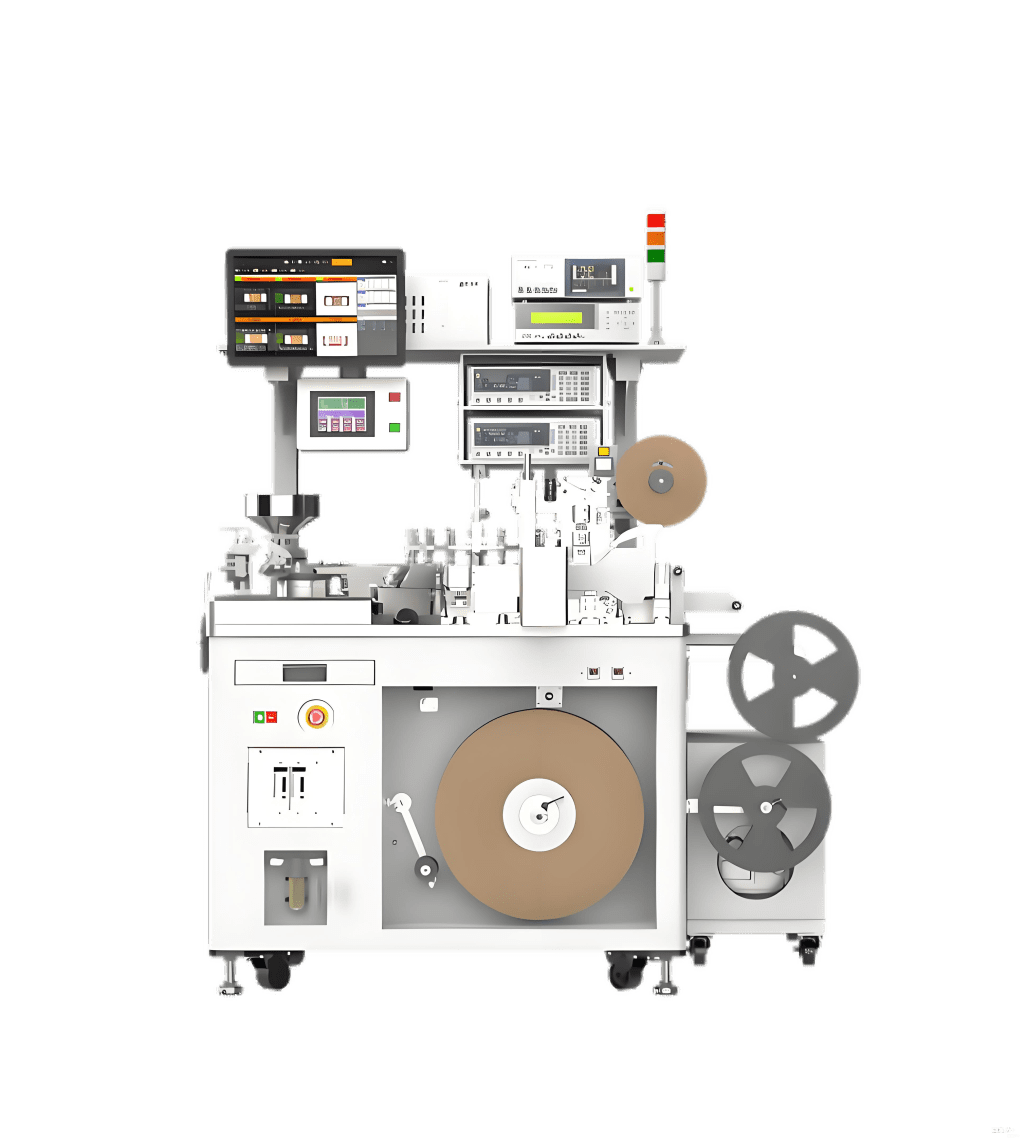

Summary: On the grand stage of electronics manufacturing, SMT pick-and-place machines are always in the spotlight. Yet behind the scenes, a critical device quietly ensures the smoothness and precision of the entire production ballet—this is the Tape and Reel Machine (T&R Machine). This FAQ delves into this indispensable automation equipment and how it becomes the cornerstone for improving efficiency, ensuring quality, and achieving digital manufacturing.

Q1: What core pain points does a Tape and Reel Machine solve in electronics manufacturing?

Answer: The T&R machine addresses the critical link between component manufacturing and PCB assembly. Its core value lies in resolving three major conflicts:

- Standardization vs. Diversity: SMT pick-and-place machines are highly standardized, high-speed robots that require uniform, correctly oriented feed. Components from upstream processes or different suppliers may come as bulk, tube, or tray, in various forms. The T&R machine acts as a “translator,” converting diversity into a standardized format (Reel) understandable by the pick-and-place machine.

- Speed vs. Reliability: Modern pick-and-place machines can theoretically place hundreds of thousands of components per hour. Manual or semi-automatic feeding becomes a bottleneck, negating the high-speed machine’s value. The T&R machine automatically prepares thousands to tens of thousands of components per hour, ensuring continuous high-speed production.

- Quality vs. Cost: Handling micro components (like 01005) manually is inefficient and prone to ESD, scratches, drops, or orientation errors. The T&R machine employs precise vision inspection and gentle pick-and-place actions to remove defective items and protect good ones, improving first-pass yield (FPY) and reducing total cost of ownership (TCO).

Q2: Beyond “packaging”: How does a T&R Machine become a critical quality checkpoint?

Answer: Modern T&R machines have evolved far beyond physical packaging. Integrated high-resolution vision inspection systems make them a vital pre-SMT quality checkpoint:

- Dimension & Shape Verification: Detect damaged, cracked, or out-of-spec components.

- Polarity/Orientation Check: Ensure correct orientation for polarized components like diodes and tantalum capacitors.

- Lead/Terminal Inspection: Identify oxidation, coplanarity issues, or solder debris.

- Marking Verification: Read part numbers, value codes, and lot numbers to match production requirements.

Any defective components are automatically removed, ensuring that every part entering the SMT line is compliant, reducing rework, scrap, and inspection time.

Q3: In today’s “high-mix, low-volume” production, how does a T&R machine maintain cost-effectiveness?

Answer: This highlights the flexible manufacturing capability of modern T&R machines:

- Fast Changeover System: Modular design allows quick replacement of feeders, tape guides, and nozzles, with corresponding stored recipes. Changeover time is reduced from hours to minutes.

- Recipe Management Software: All machine settings (vision program, pick-and-place positions, heat-seal temperature) are saved electronically and can be recalled instantly, eliminating human error.

- Wide Compatibility: High-performance T&R machines handle components from tiny 0201 resistors to large QFP ICs, providing significant material adaptability.

Such flexibility ensures even small batch production is economically viable, with minimal wasted machine utilization.

Q4: What role does a T&R Machine play in building a digital, traceable smart factory?

Answer: The T&R machine acts as an important data collection point and execution node in a smart factory:

- Data Collection:

- Record actual component counts per reel

- Track real-time and historical reject rates, including rejection reasons (vision failure, pick-and-place failure)

- Monitor overall equipment effectiveness (OEE)

- Seamlessly upload data to MES via standard interfaces (SECS/GEM, TCP/IP)

- Execution Node:

- Receive work orders from MES and automatically select the correct recipe

- Print or apply labels with unique serial numbers and work order information on tapes

- Ensure each reel has complete, traceable digital identity

This enables full traceability of components in later testing or market deployment, allowing precise root cause analysis and quality control.

Q5: When investing in a T&R Machine, what factors beyond speed should be considered?

Answer: While UPH (Units Per Hour) is important, the following factors are equally critical:

- Precision & Reliability: Evaluate mechanical rigidity, core component brands (servo motors, PLCs), and design stability.

- Advanced & Upgradeable Vision System: Check camera resolution, lighting, and whether software can support future AI-based inspection algorithms.

- User-Friendliness & Technical Support: Intuitive touchscreens, clear alerts, comprehensive documentation, and prompt, professional vendor support reduce operator learning curves and downtime.

- Future Integration Capability: Ensure standard communication interfaces and open data protocols for seamless integration into current or future smart factory ecosystems.

Conclusion

The T&R machine is far more than a simple auxiliary device. As a critical hub in the electronics manufacturing ecosystem, it delivers extreme efficiency, preemptive quality control, and seamless data integration, silently multiplying the value of the entire production system. In a competitive electronics industry, investing in an advanced, reliable T&R machine has shifted from an “optional” choice to a must-have for maintaining competitiveness and achieving manufacturing excellence.

留下评论