Abstract

In the field of Surface Mount Technology (SMT), the Tape and Reel (T&R) machine serves as a core device for back-end component preparation, yet its strategic value is often underestimated. This paper aims to systematically answer the eight most critical questions regarding T&R machines, providing an in-depth analysis of their technical principles, selection considerations, process optimization, and role in Industry 4.0. Beyond operational manuals, this work provides engineers, managers, and strategists with a reference on how to maximize ROI, integrate T&R machines into digital production flows, and leverage them for smart manufacturing.

Keywords: Tape and Reel Machine; SMT; Automation; Component Packaging; Quality Control; Smart Manufacturing; Industry 4.0

Introduction

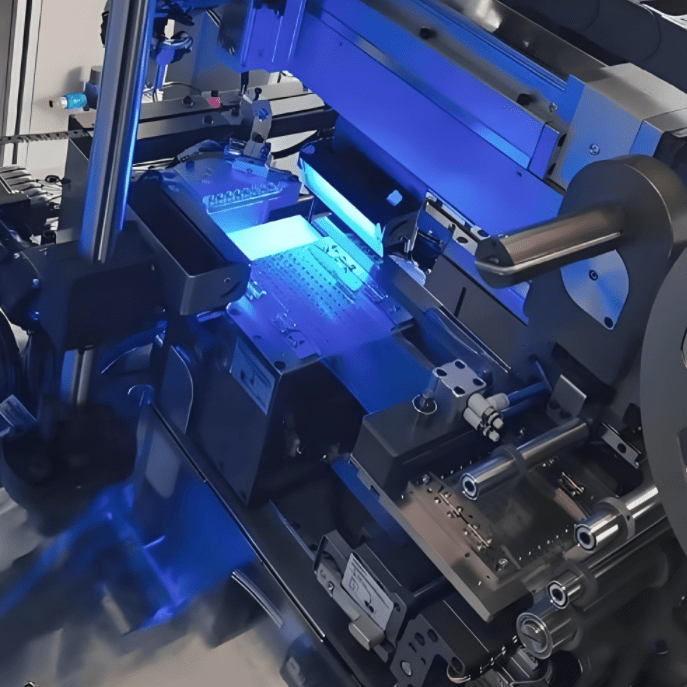

On a modern SMT production line, high-speed pick-and-place machines install tens of thousands of components on PCBs with remarkable precision. But how are these components efficiently, reliably, and compatibly presented to the machines? The answer lies in the T&R machine, an automated platform that converts chaotic bulk components into neatly organized reels. With miniaturization of components, shorter product lifecycles, and the rise of high-mix, low-volume production, T&R machines have evolved from simple back-end packaging devices to key nodes influencing efficiency, quality, and flexibility across the production line. This paper addresses the eight core questions regarding T&R machines, revealing their inner workings and future potential.

Question 1: What is the basic working principle of a T&R machine, and how do its core subsystems coordinate precise operations?

A T&R machine is a paradigm of precision mechatronics and optics integration, operating as a highly coordinated automated loop. Its core subsystems include:

1. Feeding and Orientation System

The process begins here, converting chaotic bulk material into organized flow. Common devices include vibration feeders, whose internal tracks are precisely designed. Electromagnetic vibrations orient components based on geometry and center of mass, guiding them into a linear track in the correct posture. For delicate components, vision-assisted orientation or flexible tray feeding may be used.

2. Vision Inspection System

The “eyes” of the T&R machine and a crucial quality barrier. Components pass through high-resolution CCD cameras that capture top, bottom, or side images, comparing them with predefined good-part standards. Key inspections include:

- Dimensions & Form: Detect cracks, chips, or size deviations.

- Polarity/Orientation: Ensure polarized components are correctly oriented.

- Leads/Pins: Inspect oxidation, coplanarity, and contamination.

- Marking Verification: Read and verify printed identifiers.

Non-conforming components are logged and rejected downstream.

3. Pick-and-Place & Positioning System

The “precision hand” of the machine, typically consisting of a multi-nozzle head and high-precision linear or servo motors. Components are picked after vision inspection and placed into continuously advancing carrier tape pockets with micrometer accuracy, directly affecting UPH and placement precision.

4. Carrier Tape Handling & Sealing System

Carrier tape is intermittently advanced under servo control. After placement, the cover tape is sealed by heat or ultrasonic sealing.

- Heat sealing controls temperature, pressure, and time precisely.

- Ultrasonic sealing uses high-frequency vibration to generate heat, providing speed, minimal thermal impact, and material versatility.

5. Reel Winding & Control System

Sealed tape is neatly wound onto reels with tension control. PLCs and industrial computers coordinate sensors, motion, recipes, and production data, acting as the brain of the process.

Question 2: Beyond UPH, what critical technical parameters should be considered when selecting a T&R machine?

While UPH (units per hour) is important, comprehensive evaluation includes:

1. Component Compatibility

- Size Range: From 01005 (0.4mm x 0.2mm) to large QFPs, connectors, or irregular shapes.

- Carrier Tape Width: Support for 8–56mm or wider. Quick-change vs. full module replacement impacts flexibility and precision.

2. Vision System Performance

- Camera Setup: Single vs. multi-camera systems (top + bottom). High-resolution cameras (≥5MP) detect micro-defects.

- Lighting: Programmable multi-channel ring lights highlight defects.

- Algorithm Intelligence: AI/deep learning improves defect detection, reducing false positives.

3. Precision & Stability

- Pick-and-place accuracy: Typically ±0.05mm or better.

- Repeatability: Long-term system stability.

- MTBF & MTTR: Directly affect total cost and production reliability.

4. Flexibility

- Changeover Time: Quick-change modules and recipe management reduce downtime in high-mix production.

- Recipe Storage & Retrieval: Enables rapid and consistent setup.

5. Automation & Integration

- Material Handling Interface: Support for AGV/ASRS integration.

- Communication Protocols: SECS/GEM, TCP/IP for MES connectivity.

Question 3: How does the T&R machine achieve superior quality control via its vision system?

1. Beyond Human Limits

- Precision & Consistency: Micron-level detection, 24/7 stable performance.

- Speed: Millisecond-level image acquisition and analysis, matching high-speed production.

2. Multi-Dimensional Inspection

- Top Camera: Printing, surface defects.

- Bottom Camera: Lead oxidation, plating issues, coplanarity.

- Side Camera: Height and side-wall defects.

3. Data-Driven Insights

Every inspection generates traceable data, enabling defect Pareto charts, trend analysis, and archived images for root-cause analysis.

4. AI Enhancement

Deep learning models detect complex defects beyond traditional algorithms, reducing false positives while maintaining high detection rates.

Question 4: How does the T&R machine maintain economic viability and efficiency in high-mix, low-volume production?

1. Rapid Changeover Systems

- Modular Design: Key parts (vibratory tracks, guides, suction heads) as plug-and-play modules reduce changeover time from hours to minutes.

- Recipe Call: All parameters stored electronically, enabling instant setup.

2. Broad Component Compatibility

Covers a wide range of components, avoiding repeated specialized equipment purchases.

3. Reduced Economic Lot Thresholds

Optimized changeovers allow even small batches (e.g., 5,000 components) to be economically viable.

4. MES Integration for Flexible Scheduling

Automatically prepares next job recipe and materials, supporting one-piece flow.

Question 5: Best practices for operating and maintaining a T&R machine to maximize uptime

1. Daily Operations

- Clean, dry, and debris-free bulk materials.

- Use recommended carrier and cover tapes.

- Record parameter adjustments.

- End-of-day cleaning of feeder, tracks, and suction heads.

2. Preventive Maintenance

- Daily, weekly, monthly, quarterly, and yearly tasks for cameras, motors, tracks, and calibration.

3. Spare Parts & Training

- Strategic spare inventory and operator training for troubleshooting.

4. Data Monitoring & Predictive Maintenance

Trend monitoring of key parameters (servo current, feeder load, seal head temperature) enables predictive interventions.

Question 6: How to calculate total cost of ownership and ROI for a T&R machine?

1. Components of Total Cost of Ownership (TCO)

- Purchase price, operational energy and consumables, maintenance, labor, quality, downtime.

2. ROI Benefits

- Labor savings, increased SMT throughput, quality cost savings, reduced material waste, optimized WIP and inventory.

Typical ROI cycle: 6–18 months.

Question 7: Future T&R technologies and role in Industry 4.0

1. Technological Trends

- AI-enabled vision, predictive maintenance, adaptive parameters.

- Extreme flexibility with universal platforms.

- 3D-printed pockets for irregular components.

- Modular, reconfigurable design.

2. Industry 4.0 Role

- Data Producer: Real-time component, performance, and material data.

- Edge Computing Node: Real-time analysis and local decision-making.

- Self-Optimizing System: Adjust inspection strategies based on upstream failures.

- Full Lifecycle Traceability: Each reel linked with unique identifiers and quality data.

Question 8: How to seamlessly integrate a T&R machine into automated lines and information systems?

1. Mechanical & Electrical Integration

- Automated material flow via conveyors, AGVs, or robots.

- Standardized I/O and industrial network interfaces (Ethernet/IP, Profinet).

2. Information System Integration

- Support SECS/GEM or OPC UA protocols.

- MES integration: job download, recipe call, real-time data reporting, traceability.

- ERP/WMS: real-time material consumption feedback for inventory and finance.

Phased implementation is recommended: start with basic status/data collection, then advance to job management and full traceability, ensuring strong vendor support.

Conclusion

Once considered a simple back-end packaging tool, the T&R machine has become a strategic asset in electronics manufacturing. Through the eight core questions, we see that a modern, integrated T&R machine, with unmatched efficiency, upstream quality control, exceptional flexibility, and data-driven smart manufacturing support, profoundly impacts competitiveness. In today’s rapidly evolving technology landscape, understanding and strategically investing in T&R machines is no longer optional but essential for manufacturers pursuing excellence.

留下评论