Abstract

In the era of high-speed electronics manufacturing, tape and reel machines have become indispensable tools in SMT production lines. They convert loose or tray-packaged components into standardized carrier tapes, seal them with cover tapes, and wind them onto reels, ready for high-speed pick-and-place machines.

Despite their widespread use, many engineers, production managers, and procurement specialists often have questions about their working principles, types, operation, maintenance, and selection. This article answers the most frequently asked questions about tape and reel machines, offering a thorough understanding of their components, applications, troubleshooting, and future trends. Whether you are new to SMT manufacturing or a seasoned professional seeking clarity, this guide provides actionable insights and practical knowledge to optimize production efficiency and quality.

Table of Contents

Chapter 1: Introduction – Why Tape and Reel Machines Are Vital

1.1 What is a Tape and Reel Machine?

1.2 Why Are They Essential for SMT Lines?

1.3 Common Misconceptions in the Industry

Chapter 2: Basic Components and Working Principles

2.1 Carrier Tape and Cover Tape: Standards and Materials

2.2 Pick-and-Place Head: Types and Features

2.3 Feeders: Vibratory, Tray, and Tube Feeding Systems

2.4 Vision Systems: Inspection and Alignment

2.5 Motion Control and Servo Systems

Chapter 3: Types of Tape and Reel Machines

3.1 Manual, Semi-Automatic, and Fully Automatic Machines

3.2 Component-Specific Machines: Standard, Special-Shaped, Wafer-Level

3.3 High-Speed vs. Standard Machines

3.4 Modular vs. Integrated Machines

Chapter 4: Frequently Asked Questions (FAQs)

4.1 What Types of Components Can Be Processed?

4.2 How to Choose the Right Machine for My Production?

4.3 What Are the Key Specifications to Compare?

4.4 How Do I Ensure Consistent Accuracy and Quality?

4.5 What Maintenance Practices Are Critical?

4.6 How to Troubleshoot Common Issues?

4.7 How Do Tape and Reel Machines Integrate with SMT Lines?

4.8 What Are Typical Costs and ROI Considerations?

Chapter 5: Operation, Programming, and Safety

5.1 Standard Operating Procedures

5.2 Programming Recipes for Different Components

5.3 Daily, Weekly, and Monthly Maintenance Routines

5.4 Safety Protocols and Best Practices

Chapter 6: Applications and Benefits

6.1 SMT Production Lines

6.2 Semiconductor Packaging and Testing

6.3 Automotive, Aerospace, and Medical Electronics

6.4 Operational Efficiency and Cost Reduction

6.5 Quality Assurance and Traceability

Chapter 7: Challenges and Future Trends

7.1 Miniaturization and Micro-Component Handling

7.2 Industry 4.0 and Smart Factory Integration

7.3 Flexible Manufacturing and Quick Changeover

7.4 Sustainable Materials and Energy Efficiency

7.5 Emerging Technologies in Tape and Reel Automation

Chapter 8: Conclusion

Appendix: Glossary of Terms

Tape and reel machine: Frequently Asked Questions

Chapter 1: Introduction – Why Tape and Reel Machines Are Vital

1.1 What is a Tape and Reel Machine?

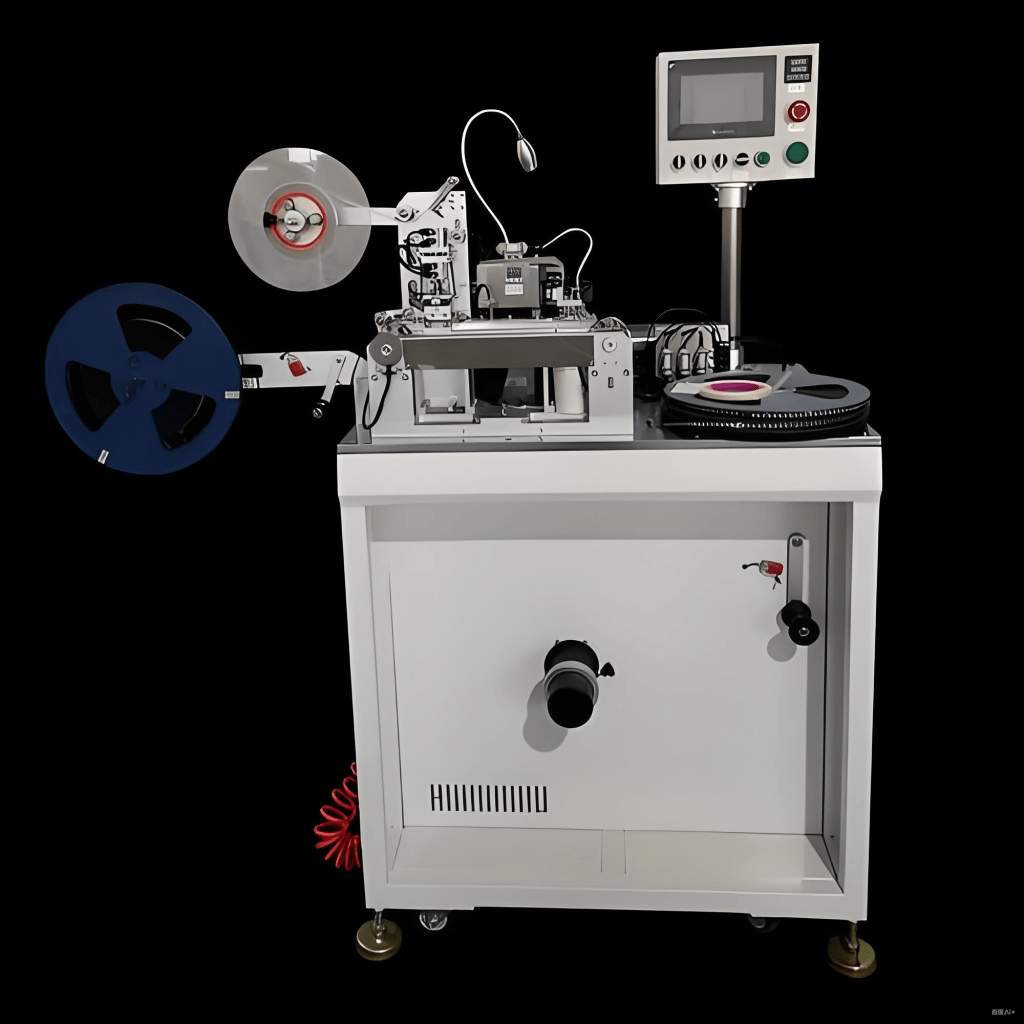

A tape and reel machine is a specialized automation device used to package electronic components into carrier tapes, cover them with protective cover tape, and wind them onto reels ready for SMT pick-and-place machines. Components may come in bulk, tube, or tray formats. The machine precisely places each component into a tape pocket, ensures correct orientation, seals the cover tape, and reels the finished tape.

1.2 Why Are They Essential for SMT Lines?

Modern SMT lines operate at extremely high speeds, often placing tens of thousands of components per hour. Manual feeding is impossible due to speed, consistency, and the risk of damage. Tape and reel machines standardize the supply, reduce handling errors, improve throughput, and allow traceability for quality control.

1.3 Common Misconceptions in the Industry

Some assume all tape and reel machines are identical. Differences in feed systems, pick-and-place heads, vision capabilities, sealing mechanisms, and motion control can significantly impact performance. Selecting a machine without understanding specifications may lead to inefficiency or increased maintenance costs.

Chapter 2: Basic Components and Working Principles

2.1 Carrier Tape and Cover Tape: Standards and Materials

Carrier tapes are plastic or paper strips that conform to EIA-481 standards. Pocket pitches range from 2mm to 44mm. Cover tapes are heat-sealed onto the carrier, protecting components while allowing visual inspection. Anti-static and transparent options ensure safe handling of sensitive components.

2.2 Pick-and-Place Head: Types and Features

- Pneumatic heads: Low-cost, simple, limited speed and precision.

- Servo-driven heads: High precision, smooth motion, widely used in modern machines.

- Linear motor heads: Ultra-high-speed, minimal wear, capable of nano-level accuracy.

2.3 Feeders: Vibratory, Tray, and Tube Feeding Systems

Vibratory feeders align loose components along a track. Tray feeders handle fragile or irregular components, while tube feeders manage axial or radial components. The correct feeder ensures high accuracy and minimal damage.

2.4 Vision Systems: Inspection and Alignment

High-resolution cameras inspect components for defects, check polarity, and measure positioning. Software calculates positional offsets and communicates with motion control for precise placement.

2.5 Motion Control and Servo Systems

Industrial PLCs or PC-based controllers synchronize motors, actuators, and sensors to ensure coordinated and precise operations.

Chapter 3: Types of Tape and Reel Machines

3.1 Manual, Semi-Automatic, and Fully Automatic Machines

- Manual: Operators place components; machine handles sealing and reeling. Speed <1,000 CPH.

- Semi-Automatic: Operator loads components; machine performs pick, placement, sealing. Medium speed 1,000–5,000 CPH.

- Fully Automatic: Machine integrates feeding, pick-and-place, vision, sealing, reeling. Speed >10,000 CPH.

3.2 Component-Specific Machines

- Standard: Resistors, capacitors, transistors.

- Special-shaped: Connectors, relays, filters.

- Wafer-level: Handles bare dies from wafer rings directly.

3.3 High-Speed vs. Standard Machines

High-speed machines use linear motors or multiple heads to achieve >10,000 CPH. Standard machines handle 3,000–10,000 CPH for mid-scale production.

3.4 Modular vs. Integrated Machines

Modular machines allow quick component changeover; integrated machines are fully automated but may require longer setup time.

Chapter 4: Frequently Asked Questions (FAQs)

4.1 What Types of Components Can Be Processed?

Resistors, capacitors, inductors, ICs, diodes, transistors, connectors, MEMS, microcontrollers, wafer-level dies.

4.2 How to Choose the Right Machine for My Production?

Consider production volume, component size, automation level, required precision, and budget.

4.3 What Are the Key Specifications to Compare?

- CPH (Cycles Per Hour)

- Minimum and maximum component sizes

- Feeder compatibility

- Vision system accuracy

- Reeling and tension control mechanism

4.4 How Do I Ensure Consistent Accuracy and Quality?

- Regular calibration of pick-and-place heads

- Vision system maintenance

- Using quality tapes and cover tapes

- Proper humidity, temperature, and ESD control

4.5 What Maintenance Practices Are Critical?

- Daily: Clean surfaces, cameras, and vacuum nozzles

- Weekly: Inspect feeder tracks and belts

- Monthly: Lubricate moving parts, check servo alignment

- Periodically: Update software and vision templates

4.6 How to Troubleshoot Common Issues?

- Pickup failure: Check vacuum, nozzle wear, component adhesion

- Misplacement: Inspect vision calibration and mechanical alignment

- Sealing defects: Adjust temperature, pressure, and tape type

- Component jams: Inspect feeders and track alignment

4.7 How Do Tape and Reel Machines Integrate with SMT Lines?

Output reels can be directly loaded into SMT feeders. Machine data can feed MES systems for traceability, quality control, and production planning.

4.8 What Are Typical Costs and ROI Considerations?

- Entry-level machines: $10,000–$30,000

- Mid-range machines: $30,000–$80,000

- High-speed fully automated machines: $100,000+

ROI depends on labor savings, reduced defects, and higher production efficiency.

Chapter 5: Operation, Programming, and Safety

5.1 Standard Operating Procedures

- Startup checks

- Install carrier and cover tapes

- Load components in feeders

- Select component recipe

- Start production and monitor operations

- Replace reels and check for jams

5.2 Programming Recipes for Different Components

Recipes include component size, height, pick coordinates, vision template, heat-seal parameters, and tape step distance.

5.3 Daily, Weekly, and Monthly Maintenance Routines

- Daily: Clean machine and lenses, check air pressure

- Weekly: Clean nozzles, check feeder tracks

- Monthly/Quarterly: Lubricate motion systems, calibrate vision, inspect servos

5.4 Safety Protocols and Best Practices

- Wear ESD protection

- Follow lockout/tagout procedures

- Avoid manual interference with moving parts

- Keep work area clean and free of obstacles

Chapter 6: Applications and Benefits

6.1 SMT Production Lines

Most common application; supports pick-and-place machines with standardized reels.

6.2 Semiconductor Packaging and Testing

Enables automated testing and transportation of packaged chips.

6.3 Automotive, Aerospace, and Medical Electronics

High reliability and traceability required; tape and reel ensures protection and quality control.

6.4 Operational Efficiency and Cost Reduction

Reduces manual labor, minimizes errors, supports 24/7 production.

6.5 Quality Assurance and Traceability

Visual inspection and standardized packaging ensure fewer defects and easy tracking of components.

Chapter 7: Challenges and Future Trends

7.1 Miniaturization and Micro-Component Handling

01005 and smaller components require high-precision pick-and-place heads, vision, and micro-nozzles.

7.2 Industry 4.0 and Smart Factory Integration

IoT-enabled machines, predictive maintenance, digital twins, and AI vision improve uptime and accuracy.

7.3 Flexible Manufacturing and Quick Changeover

Quick-change feeders and recipe-based automation meet diverse production requirements.

7.4 Sustainable Materials and Energy Efficiency

Eco-friendly tapes and energy-efficient motors reduce environmental impact.

7.5 Emerging Technologies in Tape and Reel Automation

- High-speed linear motor heads

- AI-enhanced defect detection

- Automated reel labeling and tracking

- Modular and reconfigurable machines

Chapter 8: Conclusion

Tape and reel machines are a critical link in modern SMT production, bridging the gap between raw components and automated assembly. They improve efficiency, protect components, ensure accuracy, and enable traceability. As electronic components continue to miniaturize and production demands grow, these machines will evolve toward higher speed, smarter vision systems, modular flexibility, and sustainable operation. Understanding their operation, selection, and maintenance is essential for any electronics manufacturing professional.

Appendix: Glossary of Terms

- CPH: Cycles per hour, speed measurement for tape and reel machines

- SMD: Surface-mount device

- SMT: Surface-mount technology

- Feeder: Component supply device

- Nozzle: Pick-up tool on the pick-and-place head

- Vision System: Camera-based inspection system

- Pitch: Distance between centers of carrier tape pockets

- Carrier Tape: Tape that holds electronic components

- Cover Tape: Protective tape sealed over carrier tape

- Reel: Spool that collects the finished tape

- Pick & Place: Process of picking up and placing components

- EIA: Electronic Industries Alliance, standard-setting body

- OEE: Overall equipment effectiveness

留下评论