Troubleshooting a Vision Inspection System: Calibration Problems is crucial for maintaining high-quality output in modern SMT lines. This guide focuses on Vision Inspection System Calibration, AOI Calibration Troubleshooting, and SMT Line Vision Adjustment, providing detailed steps, SMT case studies, and SOPs to ensure accurate inspection and minimize defects.

Troubleshooting a Vision Inspection System: Calibration Problems

Home › SMT Guides › Troubleshooting a Vision Inspection System: Calibration Problems

Table of Contents

- Introduction to Vision System Calibration Problems

- Common Calibration Issues in SMT Lines

- Step-By-Step Troubleshooting Procedures

- SMT Case Studies on Calibration Errors

- Preventive Maintenance and SOPs

- Operator Training and Best Practices

- Conclusion

Introduction to Vision System Calibration Problems

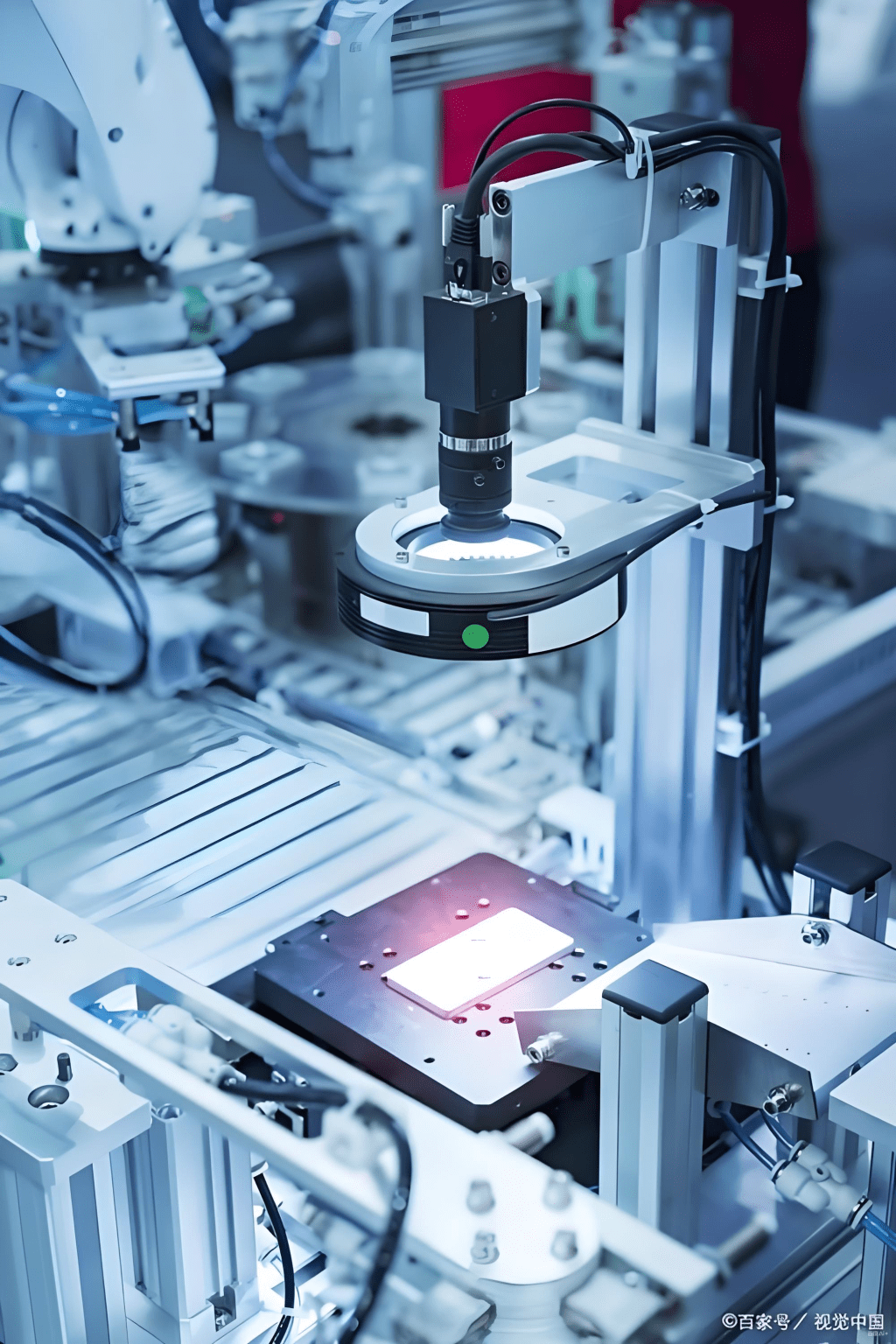

Modern SMT lines rely heavily on automated optical inspection (AOI) to ensure product quality. Any misalignment in Camera Alignment Issues or Lighting Calibration Errors can lead to false positives, missed defects, and reduced yield. Proper Inspection Accuracy Optimization is essential to maintain efficiency and reduce downtime. In this article, we cover both the technical and operational aspects of AOI Calibration Troubleshooting, equipping engineers with tools to identify, correct, and prevent calibration problems.

Common Calibration Issues in SMT Lines

- Camera Misalignment: Poorly aligned cameras can cause inconsistent defect detection across PCB boards.

- Lighting Variation: Uneven illumination results in false positives and negatives.

- Incorrect Algorithm Settings: Thresholds that are too tight or too loose impact defect detection accuracy.

- PCB Fixture Positioning Errors: Misplaced boards affect inspection precision.

- Lens Focus Drift: Over time, lenses may lose focus, requiring recalibration.

Step-By-Step Troubleshooting Procedures

Step 1: Initial System Inspection

Check all Vision Inspection System Calibration components, including cameras, lighting, lenses, and PCB fixtures. Document any visible misalignments or defects.

- Ensure cameras are securely mounted and lenses are clean.

- Check lighting uniformity across the inspection area.

- Verify PCB positioning and fixture integrity.

Step 2: Software Parameter Verification

Adjust the AOI software settings to match the current production line requirements. This includes threshold values, contrast settings, and defect size parameters.

- Use AOI Calibration Troubleshooting guides to reset software parameters.

- Run sample inspections and compare detected defects with physical inspection.

- Document any discrepancies for further adjustment.

Step 3: Camera Alignment Correction

Fine-tune camera positions to ensure accurate inspection. Utilize alignment targets or calibration boards for reference.

- Adjust X, Y, and Z positions for each camera.

- Verify lens focus and ensure no vignetting occurs.

- Check consistency of defect detection across multiple boards.

Step 4: Lighting Calibration

Ensure uniform illumination using calibration routines. Correct for shadows, reflections, or hotspots.

- Adjust intensity and angle of each light source.

- Run test boards to validate defect detection consistency.

- Document calibration results for traceability.

SMT Case Studies on Calibration Errors

Several SMT lines have faced AOI Calibration Troubleshooting challenges:

- Case 1: A high-mix SMT line experienced inconsistent defect detection due to lens drift. After implementing a weekly calibration schedule and AOI Performance Tuning, defect detection improved by 18%.

- Case 2: A PCB manufacturer had false positives caused by uneven lighting. Adjusting light angles and using AOI algorithm calibration reduced false alarms by 25%, improving throughput.

- Case 3: Misaligned camera positions in a high-speed line caused missed solder joint defects. Corrective action included Camera Alignment Issues checks and lens focus verification, raising yield by 12%.

Preventive Maintenance and SOPs

Implementing Preventive Maintenance and SOPs ensures long-term AOI system performance:

- Daily lens cleaning and visual inspection.

- Weekly calibration of cameras and lighting systems.

- Monthly software verification and threshold adjustment.

- Documenting all maintenance activities in AOI System Efficiency Optimization logs.

- Developing Calibration SOP For AOI for operators.

Operator Training and Best Practices

Operator competence is critical for effective Vision Inspection System Calibration:

- Train staff on common calibration issues and corrective actions.

- Use step-by-step visual guides for AOI False Positive Reduction.

- Regularly assess operator performance through audits and refresher training.

- Encourage documentation and feedback to refine SOPs and troubleshooting procedures.

Conclusion

Effective Troubleshooting a Vision Inspection System: Calibration Problems involves a combination of technical adjustment, preventive maintenance, operator training, and case-based learning. Applying these steps ensures SMT Line Vision Adjustment accuracy, reduces defects, and maximizes yield. Integrating AOI Calibration Troubleshooting routines and Inspection Accuracy Optimization strategies makes AOI systems more reliable and production-ready.

Author: SMT PACK LAB Technical Team · Updated: 2025-11-07

留下评论