Integrating a Vision Inspection System in modern electronics manufacturing lines is crucial to ensure high yield, precise defect detection, and optimized production efficiency. This guide provides step-by-step instructions covering everything from AOI setup, calibration, lighting optimization, software configuration, MES integration, and preventive maintenance, with practical SMT case studies and SOP examples.

Table of Contents

- Introduction to AOI Integration

- Vision Inspection System Setup

- Calibration and Lighting Optimization

- Software Configuration and AOI Programming

- SMT Line Integration Steps

- MES Integration and Data Logging

- Operator Training and SOP

- Preventive Maintenance and Troubleshooting

- SMT Case Studies

- Conclusion

Introduction to AOI Integration

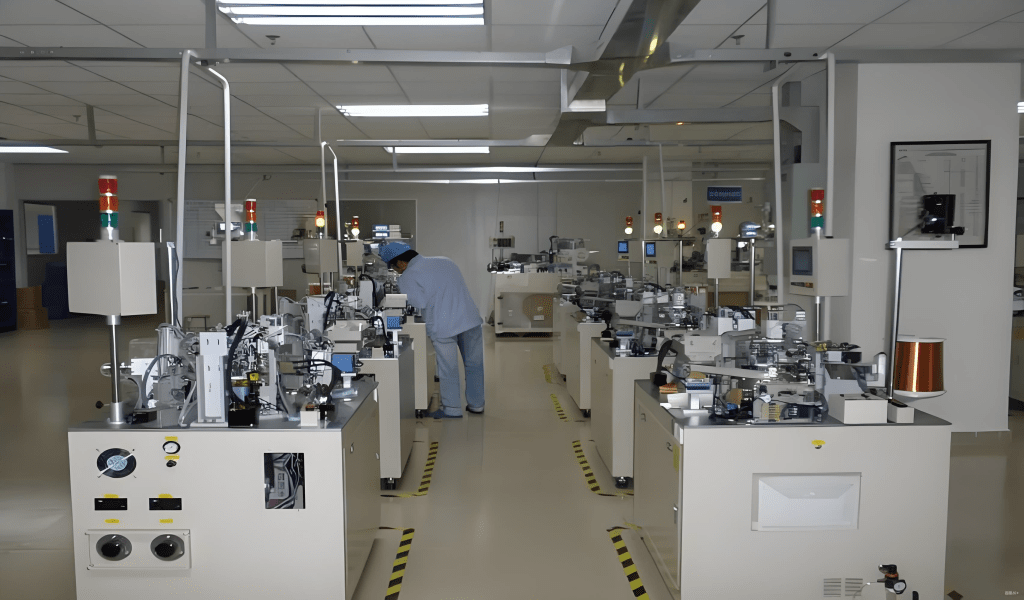

The integration of a Vision Inspection System or Automated Optical Inspection (AOI) into electronics manufacturing enhances quality control, reduces defects, and improves production throughput. Understanding key concepts like inspection accuracy, lighting, camera positioning, and software configuration is essential before beginning the integration process.

Vision Inspection System Setup

Step 1: Physical Installation

Install the AOI system on a stable platform or integrate directly with the PCB conveyor line. Ensure:

- Level mounting to prevent vibration-induced errors.

- Proper clearance for board feeding and output handling.

- Safety barriers and interlocks for operator protection.

Step 2: Electrical and Network Connections

Connect the AOI system to the main power supply and ensure:

- Voltage regulation and grounding are within specified limits.

- Network connectivity is established for MES or data logging.

- Emergency stop functionality is operational.

Calibration and Lighting Optimization

Step 3: Camera Alignment

Align cameras to ensure proper field of view and accurate component detection:

- Use calibration boards to verify image alignment.

- Adjust focus and tilt for uniform clarity.

- Document camera positions for repeatability.

Step 4: Lighting Setup

AOI lighting must be optimized for consistent inspection quality:

- Adjust intensity, angle, and type (LED, diffuse) for component contrast.

- Test under production speed conditions.

- Maintain a record of lighting settings for different PCB types.

Software Configuration and AOI Programming

Step 5: AOI Recipe Creation

Create custom inspection recipes for each PCB type:

- Define component libraries, inspection zones, and tolerances.

- Use defect classification algorithms for accurate detection.

- Integrate data logging for statistical process control.

Step 6: AOI Workflow Optimization

Optimize AOI operation for production efficiency:

- Implement batch processing where possible.

- Enable adaptive inspection based on PCB variations.

- Minimize false positives and false negatives through iterative testing.

SMT Line Integration Steps

Step 7: Conveyor Integration

Integrate the AOI system with SMT line conveyors:

- Ensure smooth PCB transfer through inspection zone.

- Sync AOI scanning speed with line throughput.

- Use sensors to detect board presence and trigger inspection.

Step 8: Feedback and Line Communication

Connect AOI outputs to line controllers for process adjustments:

- Automatic rejection of defective boards.

- Feedback loop to pick-and-place machines if needed.

- Real-time status monitoring for operators.

MES Integration and Data Logging

Step 9: MES Connectivity

Integrate AOI with Manufacturing Execution System (MES):

- Enable defect data logging by lot or serial number.

- Track yield metrics per shift and production line.

- Support SPC and trend analysis for continuous improvement.

Operator Training and SOP

Step 10: Operator Guidelines

Train operators to handle AOI efficiently:

- Follow SOP for setup, inspection, and maintenance.

- Recognize and troubleshoot common issues.

- Document inspection deviations and corrective actions.

Preventive Maintenance and Troubleshooting

Routine Checks

Maintain peak performance through preventive maintenance:

- Daily lens and lighting inspection.

- Weekly calibration verification.

- Monthly software updates and system tuning.

SMT Case Studies

Case Study 1: High-Density PCB Inspection

Implementation of AOI with custom lighting and recipe programming reduced defects by 35% on a high-density PCB assembly line. Operators were trained using detailed SOPs, ensuring consistent throughput of 1200 PCBs/hour.

Case Study 2: Integration with MES

Integration of AOI defect data with MES allowed real-time yield monitoring. Early detection of solder paste misalignment saved approximately $50,000 per quarter in scrap reduction and rework costs.

Conclusion

Integrating a Vision Inspection System in electronics manufacturing requires careful attention to installation, calibration, software configuration, SMT line integration, MES connectivity, and operator training. Following step-by-step procedures, preventive maintenance, and SOP guidelines ensures high yield, accurate defect detection, and maximum production efficiency.

Author: SMT PACK LAB Technical Team · Updated: 2025-11-07

留下评论