Configuring a laser marker for SMT production requires precise steps to ensure high throughput, marking accuracy, and minimal downtime. This guide outlines practical procedures for alignment, calibration, fixture setup, preventive maintenance, and operator training to optimize SMT line efficiency.

Table of Contents

- Introduction

- Laser Marker Alignment

- Calibration And Settings

- Fixture And Board Setup

- Maintenance And Daily Checks

- Workflow Optimization And SOP

- Safety Precautions

- Conclusion

Introduction

Laser markers provide essential traceability and coding on SMT lines. Proper setup ensures accurate marking, reduces errors, and maintains consistent production quality. Following a structured step-by-step approach allows operators to optimize output efficiently.

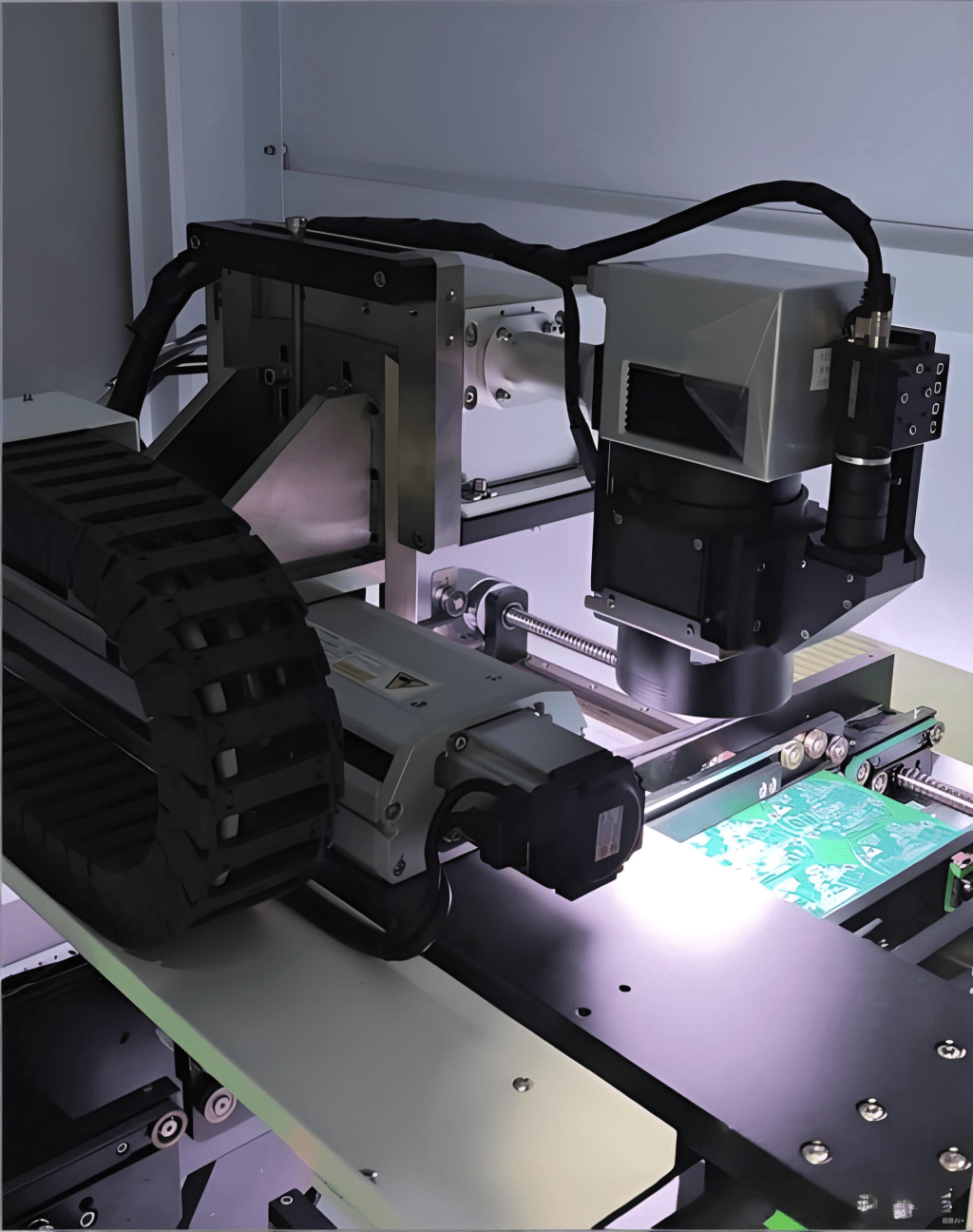

Laser Marker Alignment

Check Laser Focus

Verify laser focus relative to PCB or fixture surface. Run test markings and adjust focus screws or software offsets for precise alignment. Position Fixtures Accurately

Ensure boards are correctly positioned in fixtures. Misaligned boards can cause marking errors. Regularly inspect clamps, pins, and stoppers.

Calibration And Settings

Adjust Power And Speed

Set laser power, frequency, and marking speed according to PCB material and IC types. Incorrect settings may damage the board or reduce readability. Configure Software And Firmware

Ensure software is up-to-date and firmware matches hardware. Configure batch processing, marking patterns, and MES integration for efficient operations.

Fixture And Board Setup

- Check all clamps, pins, and stoppers for wear.

- Ensure PCB alignment is consistent across batches.

- Perform sample runs to verify fixture setup.

Maintenance And Daily Checks

- Clean laser lens and protective glass daily.

- Inspect mirrors, optical paths, and cables weekly.

- Maintain error logs and adjust parameters accordingly.

- Perform monthly calibration verification.

Workflow Optimization And SOP

Create standardized SOPs covering setup, calibration, maintenance, and troubleshooting. Train operators thoroughly and keep internal links for reference: More Laser Marker Guides.

Safety Precautions

Laser Safety

Operators must wear protective eyewear, follow interlock procedures, and observe safety protocols to prevent accidents. Emergency Procedures

Define steps for software errors, power failures, or accidental exposure. Keep emergency contacts and SOP accessible near the workstation.

Conclusion

Following this step-by-step guide ensures a properly configured laser marker, maximizing efficiency and accuracy on SMT lines. Structured alignment, calibration, fixture setup, preventive maintenance, and operator training all contribute to consistent, high-quality marking output.

Author: SMT PACK LAB Technical Team · Updated: 2025-11-07

留下评论