Proper calibration of a tray loader is essential for precision and efficiency in electronics manufacturing. This guide provides a step-by-step process to ensure your tray loader is accurately aligned, calibrated, and optimized for stable operation in SMT lines. For more technical guidance, visit SMT Pack Lab.

Table of Contents

- 1. Preparation Before Calibration

- 2. Mechanical Calibration Steps

- 3. Electrical & Sensor Calibration

- 4. Software Configuration

- 5. Testing & Verification

- 6. Common Calibration Issues

- 7. Maintenance Tips

- 8. Conclusion

1. Preparation Before Calibration

Ensure the workspace is clean, level, and ESD-safe. Gather necessary tools such as leveling meters, torque wrenches, and calibration jigs. Verify that the tray loader is properly installed according to the Equipment Selection Guide.

2. Mechanical Calibration Steps

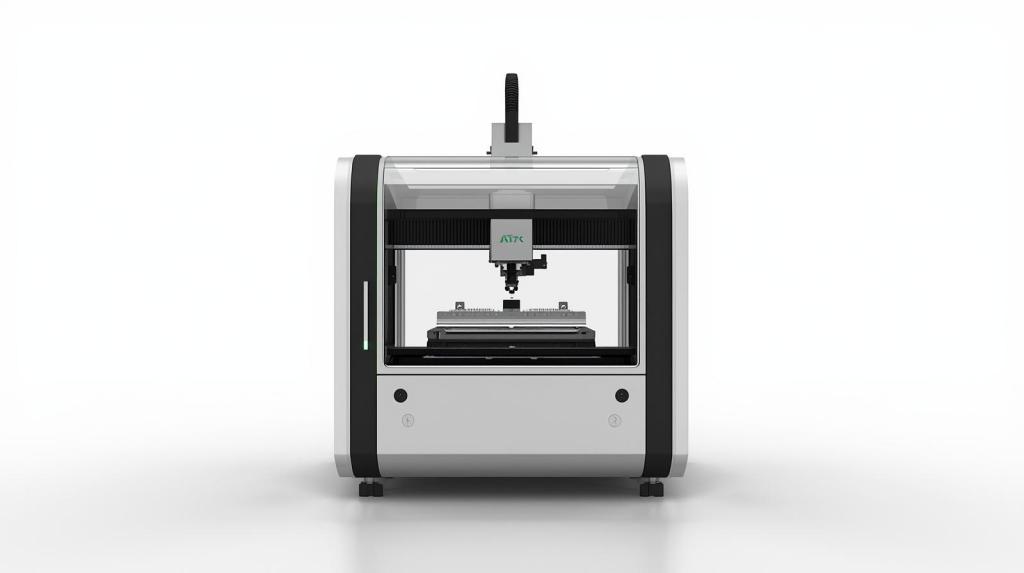

Start with the physical alignment of the tray loader. Proper mechanical calibration prevents misfeeds and component misalignment.

🔧 Step-by-Step Mechanical Calibration

- Check that the loader frame is level and secured.

- Adjust tray guides to match the standard tray width.

- Verify the tray magazine height aligns with pick-and-place machines.

- Tighten all mechanical fasteners and lock positions.

3. Electrical & Sensor Calibration

Connect all sensors, switches, and power supplies. Ensure the sensors are aligned and functioning correctly. Refer to SMT Basics for sensor operation principles.

4. Software Configuration

Configure the tray loader controller for your tray types and line integration:

- Define tray dimensions and component coordinates.

- Link to MES or ERP system if applicable.

- Set safety limits and interlocks.

5. Testing & Verification

Before full production, run calibration tests with empty trays:

🧭 Testing Checklist

- Verify tray pick and drop positions.

- Confirm sensor signals are consistent.

- Run 10 dry cycles to check repeatability.

- Adjust any minor misalignments.

6. Common Calibration Issues

- Tray misalignment: Re-level the frame or adjust tray guides.

- Sensor errors: Clean sensors and verify wiring.

- Software misconfigurations: Check coordinate mapping.

See related technical articles for detailed troubleshooting tips.

7. Maintenance Tips

Regular maintenance ensures consistent calibration:

- Monthly cleaning of mechanical joints.

- Quarterly full sensor calibration.

- Lubrication of moving parts as per manufacturer guidelines.

Visit our SMT Maintenance Tips section for more details.

8. Conclusion

Accurate calibration of tray loaders maximizes production yield and minimizes errors. Following a structured process ensures reliable operation in any electronics manufacturing line. For expert advice, contact SMT Pack Lab today.

留下评论