Table of Contents

- Introduction to SMT Quality Control

- Why Quality Control Is Critical in SMT Manufacturing

- Key Methods Used in SMT Quality Control

- How the SMT QC Process Works

- Automation and AI in SMT Quality Assurance

- Common Quality Challenges in SMT Production

- Effective Solutions for SMT Quality Control

- Conclusion

Quality control (QC) in Surface Mount Technology (SMT) plays a crucial role in ensuring high production yield, consistent performance, and reliability of electronic assemblies. From solder paste printing to reflow soldering, every step in the SMT process must be carefully monitored and optimized. Without an effective QC system, defects such as tombstoning, solder bridges, or misalignment can significantly impact production efficiency and product quality.

Why Quality Control Is Critical in SMT Manufacturing

In SMT assembly lines, precision and accuracy are everything. Unlike through-hole assembly, SMT involves placing very small components onto PCBs with high density and tight tolerances. Even minor deviations can lead to defective boards. Implementing robust quality control ensures that:

- All components are correctly placed and soldered.

- Defective products are detected early before final assembly.

- Rework costs are minimized and customer satisfaction is maximized.

At SMT Pack Lab, we emphasize integrating SMT process knowledge with data-driven inspection systems to achieve optimal yield.

Key Methods Used in SMT Quality Control

1. Solder Paste Inspection (SPI)

SPI is the first stage of SMT inspection, where the solder paste thickness, volume, and alignment are measured. Automated SPI machines use 3D laser scanning to detect printing defects, ensuring accurate paste deposition. 2. Automated Optical Inspection (AOI)

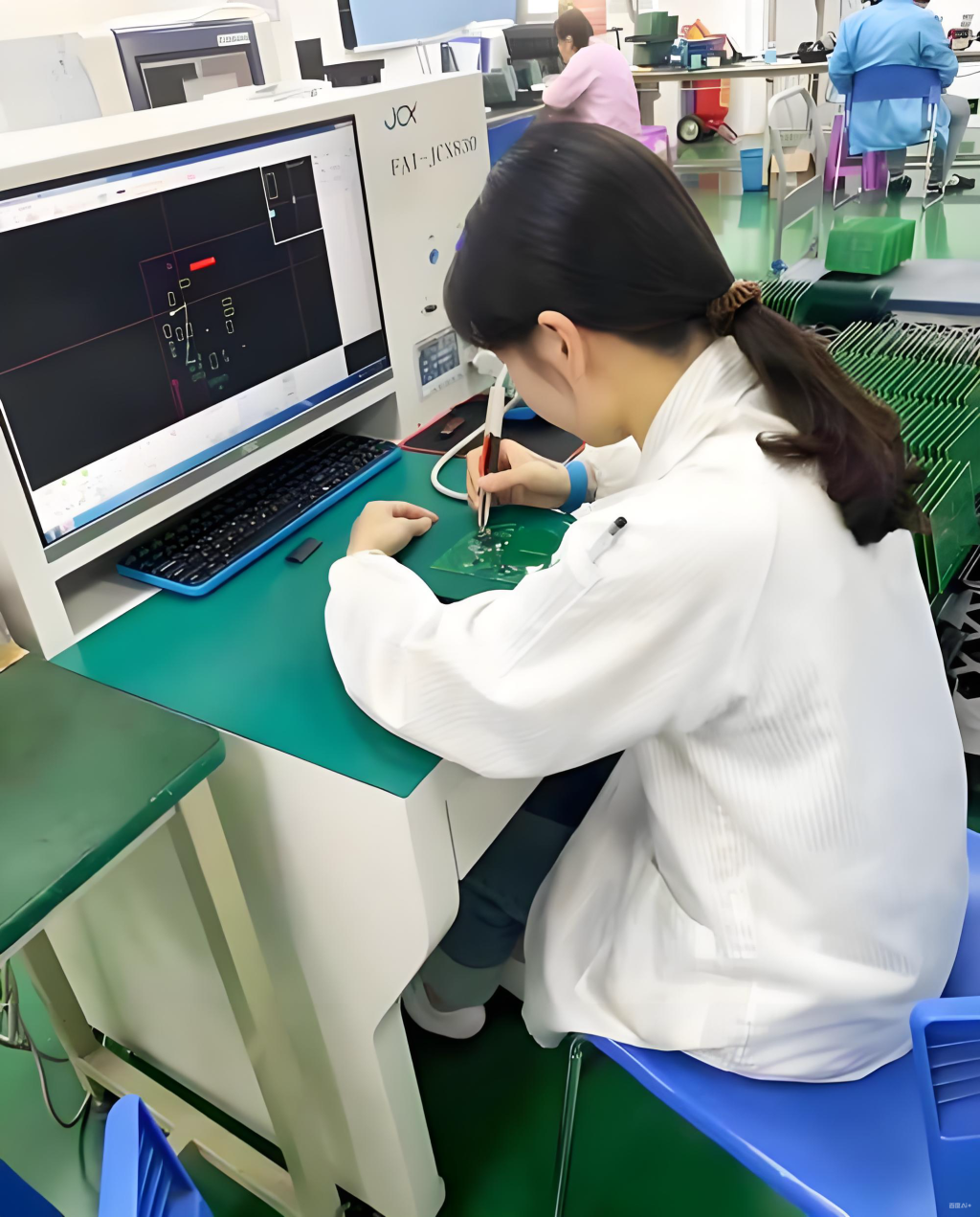

AOI systems inspect mounted components for defects like polarity errors, missing components, and solder joint quality. Modern AOI systems employ AI algorithms to distinguish between true defects and false positives. 3. X-Ray Inspection (AXI)

For hidden solder joints such as BGA or QFN packages, X-ray inspection provides a 3D visualization of internal connections, helping detect voids, short circuits, or open joints. 4. Functional Testing (ICT/FCT)

In-Circuit Testing (ICT) and Functional Circuit Testing (FCT) verify the electrical performance of completed boards. This ensures that every product leaving the line meets design specifications.

How the SMT QC Process Works

The SMT quality control process can be divided into several stages:

- Pre-production verification — Checking stencil design, PCB cleanliness, and component reels.

- In-line inspection — Continuous monitoring during printing, placement, and soldering using SPI and AOI.

- Post-reflow analysis — Evaluating solder joints through X-ray and visual inspection.

- Final testing — Conducting ICT or FCT before packaging and shipping.

This closed-loop feedback system ensures that defects are traced back to their source, enabling process improvement over time.

Automation and AI in SMT Quality Assurance

With the growing complexity of PCB assemblies, manual inspection is no longer sufficient. AI-powered vision systems and automated defect classification are now integral to modern SMT lines. These technologies help improve detection speed and accuracy while reducing human error.

Learn more about Vision Technology in SMT Automation to understand how AI and 3D imaging shape next-generation quality assurance systems.

Common Quality Challenges in SMT Production

Despite advanced inspection systems, SMT manufacturers still face several quality challenges, such as:

- Inconsistent solder paste printing due to stencil wear or humidity.

- Component misalignment from feeder calibration issues.

- Insufficient reflow temperature profiles causing cold solder joints.

- Human errors in manual rework or visual checks.

Identifying the root causes and applying corrective actions is key to continuous improvement in SMT quality management.

Effective Solutions for SMT Quality Control

To ensure reliable SMT quality, factories must integrate automation, training, and analytics. Recommended practices include:

- Using automated tray machines for stable component handling.

- Implementing MES systems for real-time traceability.

- Leveraging AI to predict defect trends and optimize production parameters.

Combined with proper operator training and preventive maintenance, these methods dramatically improve yield and reduce downtime.

Conclusion

Quality control is the foundation of successful SMT manufacturing. Through systematic inspection, automation, and data-driven analysis, manufacturers can ensure reliability and performance in every electronic product. As SMT technology continues to evolve, integrating AI-driven quality assurance will be the key differentiator in achieving a truly smart production line.

For more insights on SMT manufacturing and automation equipment, visit our main blog at SMT Pack Lab.

留下评论