For production managers and plant supervisors, installing a tape and reel machine is more than a technical upgrade; it is a strategic investment in efficiency, quality, and process reliability. This guide provides a comprehensive roadmap to implement a tape and reel system in your SMT line while maximizing throughput and ROI.

1. Understanding the Value of Tape and Reel Machines for SMT Production

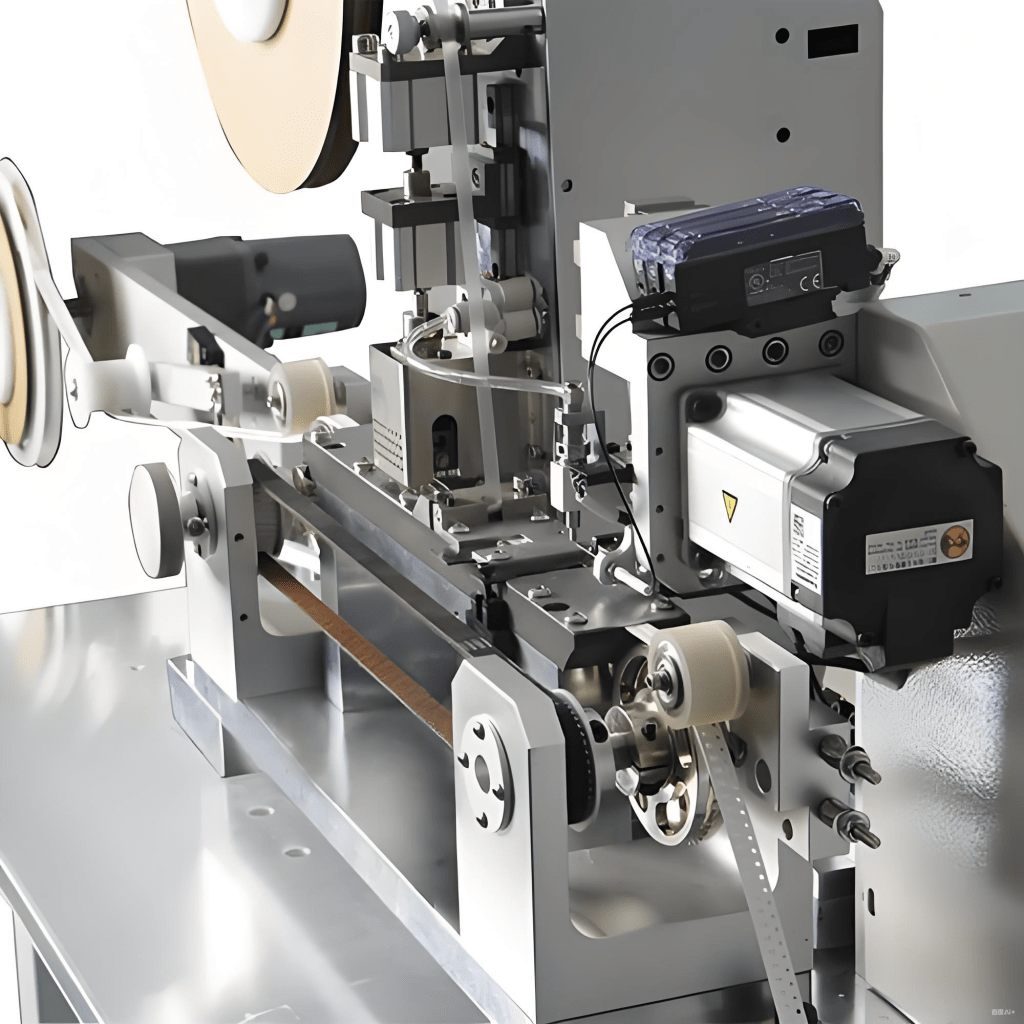

Tape and reel machines provide automated packaging of components in standard carrier tape, enabling high-speed pick-and-place operations. Key benefits include:

- Improved throughput and reduced downtime due to automated component handling.

- Minimized human error in feeding components, ensuring consistent quality.

- Efficient inventory tracking and traceability through standardized labeling.

- Streamlined workflow integration with MES systems for end-to-end production visibility.

Management-level perspective emphasizes not just the installation process but also the strategic impact on production planning and long-term operational cost reduction.

2. Strategic Planning Before Installation

Before bringing in a tape and reel machine, it’s critical to perform a thorough assessment. Planning steps include:

- Production throughput analysis: Identify bottlenecks in your current SMT line and quantify expected improvements.

- Space allocation: Map the SMT line and ensure sufficient clearance for machine operation, reel storage, and maintenance access.

- Resource planning: Ensure availability of utilities, including power, compressed air, and network connections for MES integration.

- ROI estimation: Calculate potential savings from reduced manual labor, fewer errors, and increased machine uptime.

Strategic planning ensures the tape and reel machine aligns with corporate KPIs and production goals.

3. Site Preparation and Workflow Considerations

Show/Hide Site Preparation Details

- Assess floor strength and vibration isolation to prevent misfeeds and machine wear.

- Design clear material flow paths for incoming reels, operator access, and waste disposal.

- Plan lighting and ergonomics for operators handling tapes and feeders.

- Ensure environmental conditions (temperature, humidity) match SMT component specifications.

4. Machine Unpacking, Mechanical Setup, and Layout Optimization

While technical staff perform physical installation, management oversight ensures layout optimization:

- Position the machine to minimize movement between pick-and-place stations.

- Confirm leveling and anchoring meet manufacturer specifications.

- Optimize reel placement for minimal operator intervention during changeovers.

- Verify tape path alignment to reduce mechanical stress and prevent component damage.

5. Electrical Integration and Control System Alignment

- Coordinate with IT and engineering teams to integrate the machine into MES or PLC networks.

- Ensure power supply, grounding, and safety interlocks meet facility standards.

- Verify sensors and labeling systems communicate correctly with production monitoring software.

6. Feeder Setup, Tape Handling, and Calibration

- Establish standardized procedures for loading tapes, aligning carrier tape, and tension adjustment.

- Calibrate feeders to match component dimensions and pick-and-place machine requirements.

- Perform dry runs to ensure alignment and sensor accuracy, reducing first-pass errors.

7. Commissioning, Testing, and Initial Production Runs

Commissioning is critical for management to monitor KPIs:

- Run the machine at partial speed initially and document baseline performance.

- Track component feeding accuracy, tape tension consistency, and labeling correctness.

- Gradually ramp up to full production while monitoring downtime and error rates.

- Document lessons learned for operator manuals and SOPs.

8. Operator Training and Process Standardization

Show/Hide Training Details

- Train operators on reel loading, tape threading, and feeder calibration.

- Standardize procedures for changeover and troubleshooting.

- Emphasize safety, including emergency stops and maintenance lockout/tagout procedures.

- Provide documentation and checklists for consistent process adherence.

9. Maintenance, Troubleshooting, and Efficiency Optimization

- Schedule daily, weekly, and monthly maintenance tasks to prevent downtime.

- Implement sensor calibration checks and tape path inspections.

- Use performance data to identify bottlenecks and improve throughput.

- Track KPIs: reels per shift, downtime, tape waste, and first-pass yield.

10. Integration into SMT Workflow and KPI Tracking

Management should integrate machine output into production dashboards:

- Link machine output to MES for real-time component traceability.

- Coordinate with procurement for sufficient tape and reel stock.

- Analyze production data to reduce waste and optimize staffing.

- Refer to related guides: Assembly Line Layout for SMT Efficiency.

11. Return on Investment and Strategic Benefits

Investing in a tape and reel machine provides measurable ROI:

- Reduced labor cost due to automation of repetitive tasks.

- Lower defect rates, fewer misfeeds, and less component damage.

- Increased throughput leading to higher revenue potential per SMT line.

- Enhanced traceability and compliance with industry standards.

12. Summary and Key Recommendations

- Perform strategic planning before installation to align with production goals.

- Ensure site preparation, workflow optimization, and layout efficiency.

- Integrate machine into electrical and MES systems for data-driven management.

- Invest in operator training and standardized SOPs.

- Monitor KPIs and optimize throughput for maximum ROI.

For more insights on SMT line efficiency and automation strategies, visit SMT Pack Lab or contact our experts.

留下评论