This comprehensive guide explains types of tray machines, key selection criteria, integration with SMT lines, throughput & ROI calculations, maintenance considerations and real-world selection checklists. Designed for manufacturing engineers, production managers and procurement specialists.

Contents1. Overview — What is a tray machine and why it matters2. Tray machine types explained3. Key selection factors (specs, throughput, footprint)4. Integration with pick-and-place & SMT line5. Throughput matching and feeder strategy6. Reliability, maintenance & spare parts7. ESD, MSL and handling considerations8. ROI and total cost of ownership (TCO)9. Vendor evaluation & proof points10. Practical selection checklist (downloadable)11. Short case study: small factory selection12. Conclusion & recommended resources

1. Overview — What is a tray machine and why it matters

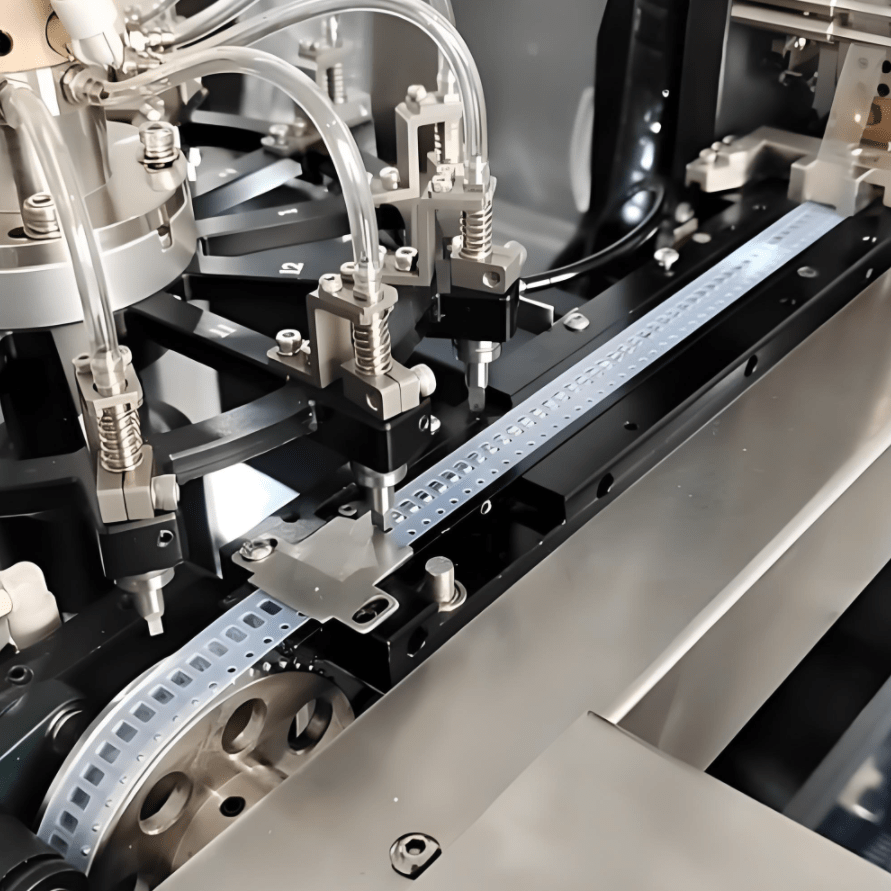

A tray machine (tray loader / tray handler) is equipment designed to load, present, and/or unload component trays for automated pick-and-place systems in SMT production. Trays are commonly used for larger, fragile, odd-shaped or heavy components that are not suitable for tape & reel feeding — for example connectors, sockets, large inductors, and some precision mechanical parts.

Choosing the right tray machine affects line efficiency, changeover time, damage rates and ultimately yield. The right machine reduces operator touch, improves feeder stability and ensures consistent tray presentation to the placement head.

2. Tray machine types explained

Tray handling equipment covers a spectrum from simple manual loaders to fully automated tray-to-feeder systems. Here are the main categories:

2.1 Manual tray loader

Operator loads trays by hand into a static tray station. Cheap and simple, ideal for prototypes and very low-volume lines but causes low throughput and higher operator dependence.

2.2 Semi-automatic tray loader

Semi-automatic units use motorized conveyors or indexing mechanisms to present trays to the pick head. They reduce operator fatigue, shorten cycle time and are common in medium-volume lines.

2.3 Fully automatic tray loader / tray changer

These systems automatically pull trays from magazines, align them precisely and feed them into the placement area. They support unattended operation, automatic magazine changes and are suited for high-mix or high-volume production.

2.4 Tray-to-feeder (tray-to-tape) automation

Advanced systems can de-tray parts and transfer them into feeder systems or even into tape for later use. This is more complex and used primarily in automated or highly integrated lines where minimizing manual handling is critical.

3. Key selection factors (specs, throughput, footprint)

When evaluating tray machines, consider technical specs, operational needs and real-world constraints. Below are the most important decision factors:

3.1 Supported tray formats & standards

Verify the machine supports your tray dimensions (JEDEC tray sizes, custom trays), tray height, pocket spacing and whether it can accept adapters for non-standard trays. Some machines include modular adapters to support multiple tray types.

3.2 Alignment accuracy & repeatability

Critical for placement accuracy. Alignment specs should be in the tens to hundreds of microns depending on your placement tolerances. Look for closed-loop vision alignment or mechanical fiducials on the tray station.

3.3 Throughput & cycle time

Match the tray machine’s cycle time to pick-and-place speed. A fast feeder/placement machine will be starved by a slow tray loader. Specify the maximum parts-per-hour (PPH) the tray system can sustain and include safe margins.

3.4 Magazine capacity & unattended run length

Higher capacity magazines mean fewer changeovers and longer unattended operation. Consider how many trays per magazine and how many parts per tray to estimate runtime between interventions.

3.5 Changeover time & operator ergonomics

Fast, tool-less changeovers reduce downtime for mixed-model production. Evaluate how the machine handles tray loading/unloading ergonomically — lower risk of operator injury speeds operations.

3.6 Footprint & factory layout

Tray machines must physically fit between or adjacent to placement machines and conveyors. Evaluate access for maintenance, replacement of magazines, and clearance for robots if integrated.

3.7 Electrical & communication interfaces

Protocols (Ethernet/IP, Modbus, Profinet, discrete I/O) and mechanical interfaces must match your pick-and-place system and MES. Verify support for feeder control or start/stop signaling to synchronize line flow.

3.8 Environmental & handling considerations

If parts are moisture-sensitive (MSL) or ESD-sensitive, the tray machine and magazines should support dry storage or ESD-safe materials. Consider integration with local humidity control or nitrogen purging where required.

4. Integration with pick-and-place & SMT line

Integration is often where selection succeeds or fails. Ask vendors how their tray machine connects to your existing pick-and-place cells.

4.1 Mechanical alignment and conveyors

Proper mechanical coupling (conveyor height, tape feeder alignment) prevents misfeeds and reduces set-up time. Consider adjustable conveyor bridges or leveling feet for fine tuning.

4.2 Communication and synchronization

Integration should allow the tray handler to pause, index, or feed trays in step with the placement machine. Support for PLC integration and standard industrial protocols is essential for reliable control.

4.3 Vision and fiducial alignment

Two strategies exist: (A) the tray machine provides accurately indexed trays; (B) the placement machine uses vision to locate each part. A robust solution often combines both — good mechanical indexing plus local vision checks — for highest reliability.

5. Throughput matching and feeder strategy

Throughput planning must account for placement speed, feeder capacity and tray changeover. Use these rules of thumb:

- Calculate your line’s peak PPH and ensure the tray handler PPH >= peak PPH × 1.2 (20% safety margin).

- Consider parallel magazines or dual-loader setups for continuous feeding during changeover.

- Optimize tray population density (parts per tray) to minimize operator interventions while respecting tray handling limits.

6. Reliability, maintenance & spare parts

Assess MTBF, recommended maintenance intervals, and availability of critical spares (motors, belts, sensors). Key items:

- Replacement belts and drive components

- Vision cameras & calibration targets

- Control board and PLC modules

- Wear items such as guide rails and gripping pads

Request a preventive maintenance schedule from vendors and check if service contracts include emergency response times for your region.

7. ESD, MSL and handling considerations

Tray machines must respect ESD protection and MSL handling if your components require it:

- ESD-safe materials for magazines and trays, grounding points, and conductive rollers.

- Pack and handle MSL parts in dry storage; consider integrated desiccant canisters or sealed magazine covers.

- Operator safety and guarding: emergency stop, light curtains, and safe access doors for service.

8. ROI and total cost of ownership (TCO)

Beyond purchase price, calculate TCO including installation, training, downtime, spare parts and expected productivity gains. Typical ROI drivers:

- Reduced labor cost from automated loading/unloading

- Higher effective runtime and fewer line stoppages

- Lower damage rates and fewer reworks

- Improved traceability and lower scrap

Example ROI estimate (simplified):

Annual parts processed: 2,000,000

Labor saving: 1 operator at $25k/year

Reduction in defects: 0.5% of parts saved × average cost per part

Additional uptime: +8% production

Calculate payback considering machine price, installation & training.

9. Vendor evaluation & proof points

When evaluating vendors, request:

- References from customers with similar products and volumes

- On-site demo or video of your specific tray format being handled

- Uptime statistics and service coverage in your region

- Formal FAT (Factory Acceptance Test) scripts and acceptance criteria

- Spare parts lead times and recommended spares kit

10. Practical selection checklist (downloadable)

Use the checklist below during vendor comparison. Keep a filled spreadsheet for side-by-side scoring.

- Supported tray formats and adapters (list exact JEDEC or custom sizes)

- Alignment accuracy (specify microns)

- Throughput PPH and magazine capacity

- Integration interfaces (Ethernet/IP, Modbus, discrete I/O)

- ESD / MSL support and environmental controls

- Changeover time and required operator actions

- Warranty, service SLA and spare parts availability

- Price, installation cost, training and estimated payback period

Downloadable quick checklist (copy/paste)

[ ] Tray sizes supported:

[ ] Alignment accuracy (µm):

[ ] Max PPH:

[ ] Magazine capacity (trays):

[ ] Integration protocol:

[ ] ESD/MSL support:

[ ] Changeover time (min):

[ ] Warranty & SLA:

[ ] Spare parts lead time:

[ ] Estimated payback (months):

11. Short case study: small factory selection

Scenario: A small contract manufacturer processes medium-volume automotive modules (100k pcs/month). They require a tray loader to present connectors and large inductors to a pick-and-place machine running at 8,000 CPH for these feeders.

Approach taken:

- Choose a semi-automatic tray loader with a 2-magazine capacity to allow hot-swap of magazines between shifts.

- Ensure alignment accuracy better than 200 µm with mechanical indexing plus one-camera vision check before each pick.

- Integrate with the placement machine via discrete I/O and use a simple PLC handshake to avoid complex protocol work.

- Calculate ROI: labor reduction 0.5 operator/day, fewer feeder jams, payback estimated 10 months.

Outcome: Implementation reduced feeder-related downtime by 60% and lowered handling damage by 75% in six months.

12. Conclusion & recommended resources

Choosing the right tray machine is a systems decision: align tray formats, throughput, integration and reliability to your actual production needs. For prototyping and low-volume runs, semi-automatic or outsourced taping/traying services may be more cost-effective. For high-volume and mixed-model lines, invest in automated tray magazines with robust vision indexing and good supplier SLA.

Related reading and tools on SMT Pack Lab:

- How to Choose the Right Tray Machine for SMT Processing (selection guide) — (this guide)

- Taping Machines & Tray Packers — FAQ & Guide — taping vs. tray trade-offs and maintenance tips.

- Contact Us — consult our team for on-site assessment, demos and ROI modeling.

If you want, we can:

- Provide a tailored tray machine shortlist based on your tray sizes and monthly volume.

- Run a payback calculation using your labor and defect cost inputs.

- Arrange a demo or video of candidate machines handling your real trays.

留下评论