Proper loading of a tape and reel machine is crucial for maintaining SMT line efficiency, preventing misfeeds, and maximizing production yield. This guide outlines the 5 essential steps to load a tape and reel machine effectively. For more SMT insights, visit SMT Pack Lab.

Table of Contents

- 1. Introduction to Tape and Reel Loading

- 2. Step 1: Prepare the Feeder

- 3. Step 2: Align the Tape Correctly

- 4. Step 3: Adjust Tape Tension

- 5. Step 4: Verify Sensor Detection

- 6. Step 5: Conduct a Test Run

- 7. Best Practices and Tips

- 8. Preventive Maintenance

- 9. Summary and Recommendations

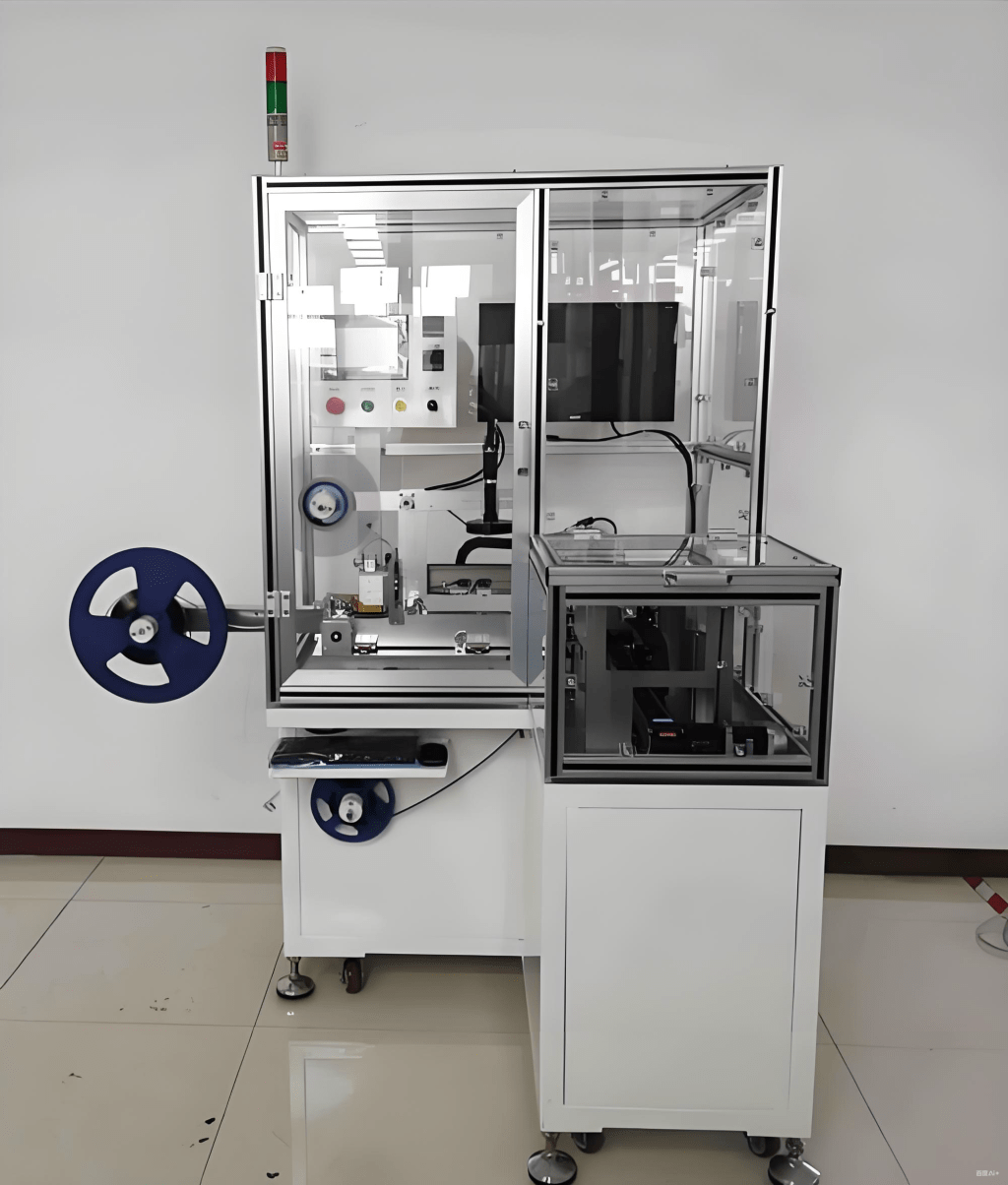

1. Introduction to Tape and Reel Loading

Loading tape and reel machines correctly ensures components are fed smoothly, reducing downtime and errors in high-speed SMT production. Correct procedure also extends the lifespan of feeders and reels.

2. Step 1: Prepare the Feeder

Show/Hide Feeder Preparation

- Clean the feeder and tape path

- Inspect for mechanical wear or damage

- Check the reel holder and locking mechanism

- Verify electrical connections and grounding

- Ensure proper feeder type is selected for component size

3. Step 2: Align the Tape Correctly

- Place the tape in the correct orientation

- Ensure sprocket holes align with feeder teeth

- Guide the tape smoothly through the path

- Check for twists or folds in the tape

- Confirm component polarity if applicable

4. Step 3: Adjust Tape Tension

- Set appropriate tension to prevent tape slippage

- Ensure tape moves smoothly without pulling on components

- Check tension for long and short reels

- Adjust tension gradually while observing feeder movement

- Verify smooth reel rotation during manual test

5. Step 4: Verify Sensor Detection

- Check all sensors are clean and operational

- Verify sensors detect components accurately

- Adjust sensor sensitivity if needed

- Ensure no false positives or missed detections

- Confirm signal integration with machine software

6. Step 5: Conduct a Test Run

- Run a small batch to verify correct feeding

- Observe tape movement and component pick accuracy

- Adjust mechanical or software settings as necessary

- Document optimal parameters for future use

- Confirm stable performance before full production

7. Best Practices and Tips

- Follow SOPs and checklists for every loading session

- Use proper reel handling to avoid tape damage

- Keep spare feeders and tape spools ready

- Train operators regularly on best loading techniques

- Document errors and improvements for continuous learning

8. Preventive Maintenance

- Regularly clean tape paths, sensors, and rollers

- Inspect feeders for wear and replace worn parts

- Lubricate mechanical parts as recommended

- Maintain detailed maintenance logs

- Check software and firmware updates periodically

9. Summary and Recommendations

- Follow the 5 key steps for efficient tape and reel loading

- Ensure mechanical, sensor, and software readiness

- Perform test runs and adjustments before full production

- Document and monitor parameters for consistency

- Maintain preventive maintenance and operator training

For more SMT optimization guides, visit SMT Pack Lab or contact our experts.

留下评论