Taping, or “Tape & Reel”, is a packaging method used in Surface Mount Technology to place electronic components into carrier tape pockets, seal them with cover tape, and wind onto reels for automated assembly.

2. Why Taping is Used

- Automated compatibility with pick-and-place machines.

- Efficient storage and handling.

- Protects components from damage and misalignment.

- Enables continuous feeding in high-volume production.

3. How Taping Works

3.1 Component Orientation

Components are oriented into carrier tape pockets manually or automatically.

3.2 Inserting Components

Parts are inserted consistently to ensure correct orientation for pick-and-place.

3.3 Cover Tape Sealing

The cover tape secures components in the tape pockets.

3.4 Reel Winding and Labeling

The taped components are wound onto reels with labels for identification.

3.5 Feeding into Pick-and-Place Machines

Reels are loaded into feeders that advance the tape for automated assembly.

Expand: Example of Tape Splicing

Splicing joins two reels together to minimize downtime in automated lines.

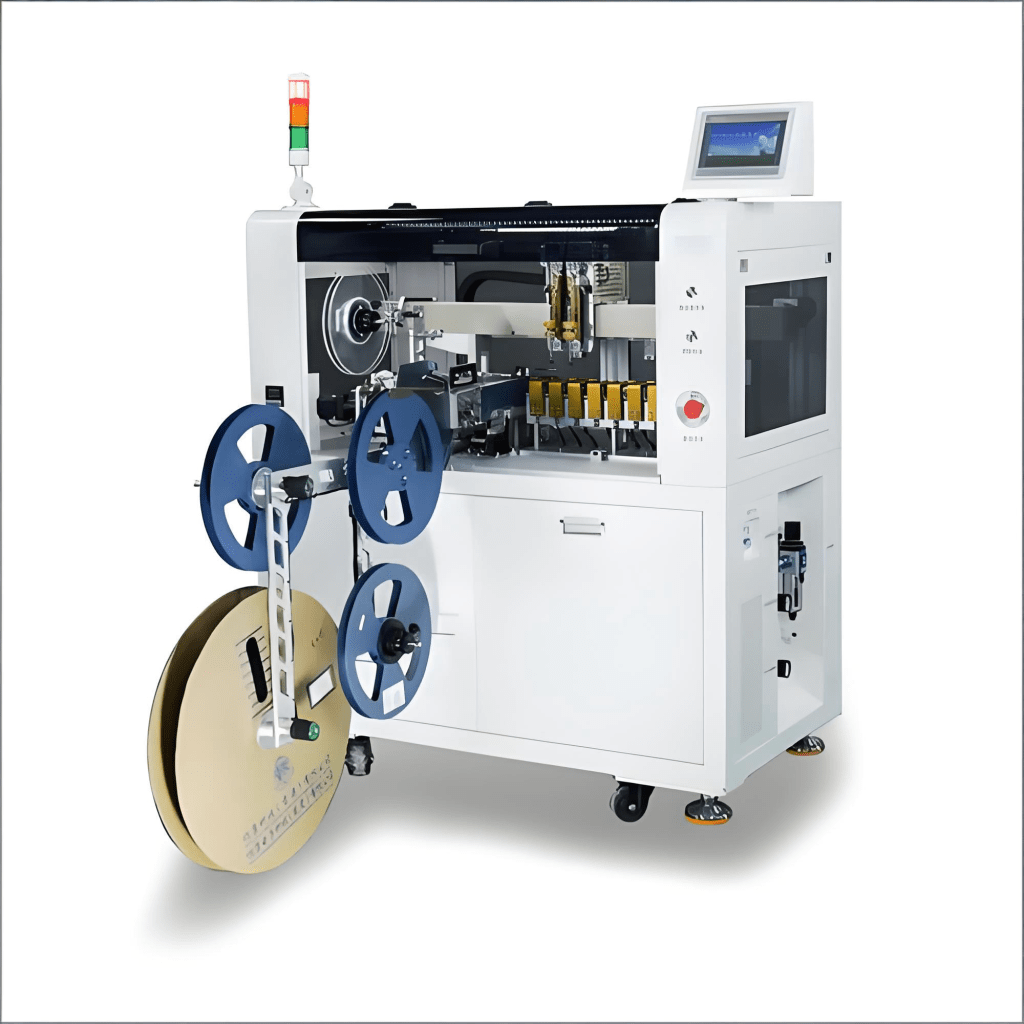

4. Key Equipment

- Taping machines / automatic tapers

- Splicing machines / tape-joiners

- SMT feeders / pick-and-place feeders

- Inspection systems for tape integrity

5. Benefits

- Higher production throughput

- Reduced component damage

- Consistency in orientation and placement

- Scalable for high-volume production

6. Common Issues

- Tape misalignment or peeling cover tape

- Missing or misoriented components

- Splice tape failure

- Static or humidity damage during storage

7. Best Practices

- Follow EIA-481 standard for tape & reel dimensions.

- Use high-quality carrier and cover tape.

- Maintain ESD-safe environment.

- Proper labeling with part info, orientation, and lot code.

- Store in cool, dry, and humidity-controlled conditions.

8. Conclusion

Taping in SMT is essential for automated, high-volume electronic assembly. Proper understanding and implementation improve throughput, reduce defects, and protect components. For more details, visit our Technical Processes section.

Contact Us for SMT taping solutions or consultation.

留下评论