1. What is a Tray Machine in SMT?

A tray machine in SMT refers to the equipment used to load, organize, and prepare electronic components in trays for pick-and-place machines. Trays are often used for delicate or larger SMD components that cannot be handled via tape & reel. For more SMT-related processes, see our Technical Processes section.

2. Types of Tray Machines

- Manual Tray Loader: Requires operators to place components into trays manually.

- Semi-Automatic Tray Machine: Combines automation with manual input to improve speed.

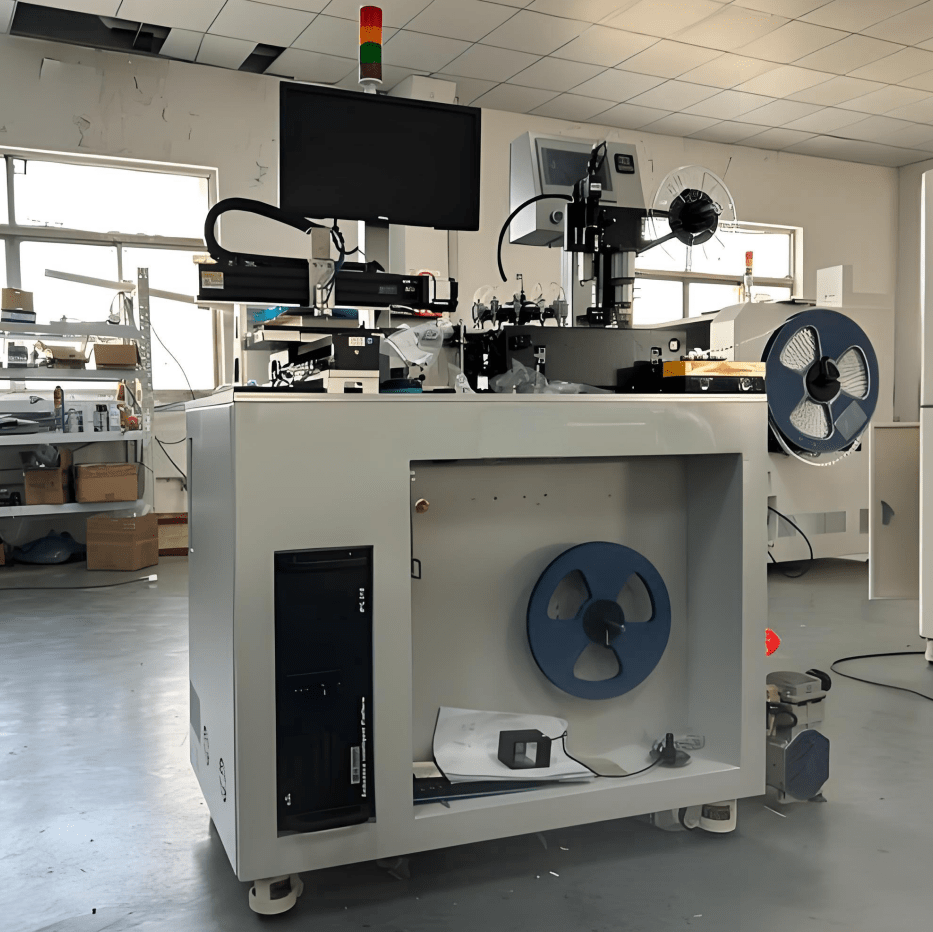

- Fully Automatic Tray Machine: Automates loading, positioning, and tray transfer for high-volume SMT production.

3. Key Factors When Choosing a Tray Machine

When selecting a tray machine, consider:

- Component size and type: Ensure the machine supports the components you use.

- Tray dimensions: Standard trays vs custom trays.

- Placement speed: Match your production line throughput.

- Precision and alignment: Critical for pick-and-place accuracy.

4. Compatibility with SMT Production Line

The tray machine should integrate seamlessly with your SMT pick-and-place system. Consider conveyor compatibility, feeder alignment, and synchronization. Learn more about feeder setup in our SMT Feeder Setup Guide.

5. Automation and Efficiency Considerations

Expand: Automation Advantages

Automated tray machines reduce labor costs, minimize errors, and increase throughput. Fully automated solutions often include vision alignment and barcode scanning for error-proofing.

6. Maintenance and Longevity

- Regular cleaning of tray guides and belts.

- Calibration to ensure proper tray positioning.

- Periodic inspection of motors, sensors, and alignment systems.

7. Common Issues and Troubleshooting

- Misaligned trays causing pick-and-place errors.

- Component jamming in tray pockets.

- Inconsistent tray feeding due to worn belts or guides.

- Check our SMT Troubleshooting Guide for more solutions.

8. Best Practices for Selecting Tray Machines

- Assess production volume and throughput requirements.

- Choose machines with compatibility for standard tray sizes.

- Ensure integration with existing SMT line automation.

- Verify manufacturer support and spare parts availability.

- Consider modular machines for future expansion.

9. Conclusion

Choosing the right tray machine is critical for efficient SMT processing, component protection, and maintaining production quality. Evaluate component types, automation needs, compatibility, and maintenance before selecting the right equipment. For more guidance, see our Technical Processes section and Contact Us for consultation.

Contact Us for professional SMT tray machine solutions.

留下评论