Case Study: Improving SMT Efficiency with Automation Solutions

Published November 1, 2025 • SMT PACK LAB

This case study shows how a mid-sized EMS factory improved SMT line throughput by 45%, reduced rework by 62%, and lowered cost-per-part by 18% after implementing targeted automation: taping/tray automation upgrades, inline vision inspection, and MES-driven traceability.

1. Executive Summary

Customer: EMS Provider (small/medium) • Problem: manual packaging, high inspection workload, frequent feeder jams. Solution: semi-automatic taping + automated tray packing, AI-assisted vision checks at taping/tray stations, MES integration for traceability. Outcome: throughput ↑45%, rework ↓62%, validated ROI within 10 months.

2. Background & Baseline Metrics

Baseline (pre-automation): 2 SMT lines, average throughput 1,200 CPH, rework rate 4.8%, manual taping/tray operations and spot QA inspections.

3. Project Objectives

- Increase overall line throughput by at least 30%.

- Reduce rework and scrap by 50% through early defect detection.

- Achieve payback within 12 months.

- Improve inventory traceability for taped reels and trays.

4. Automation Solutions Implemented

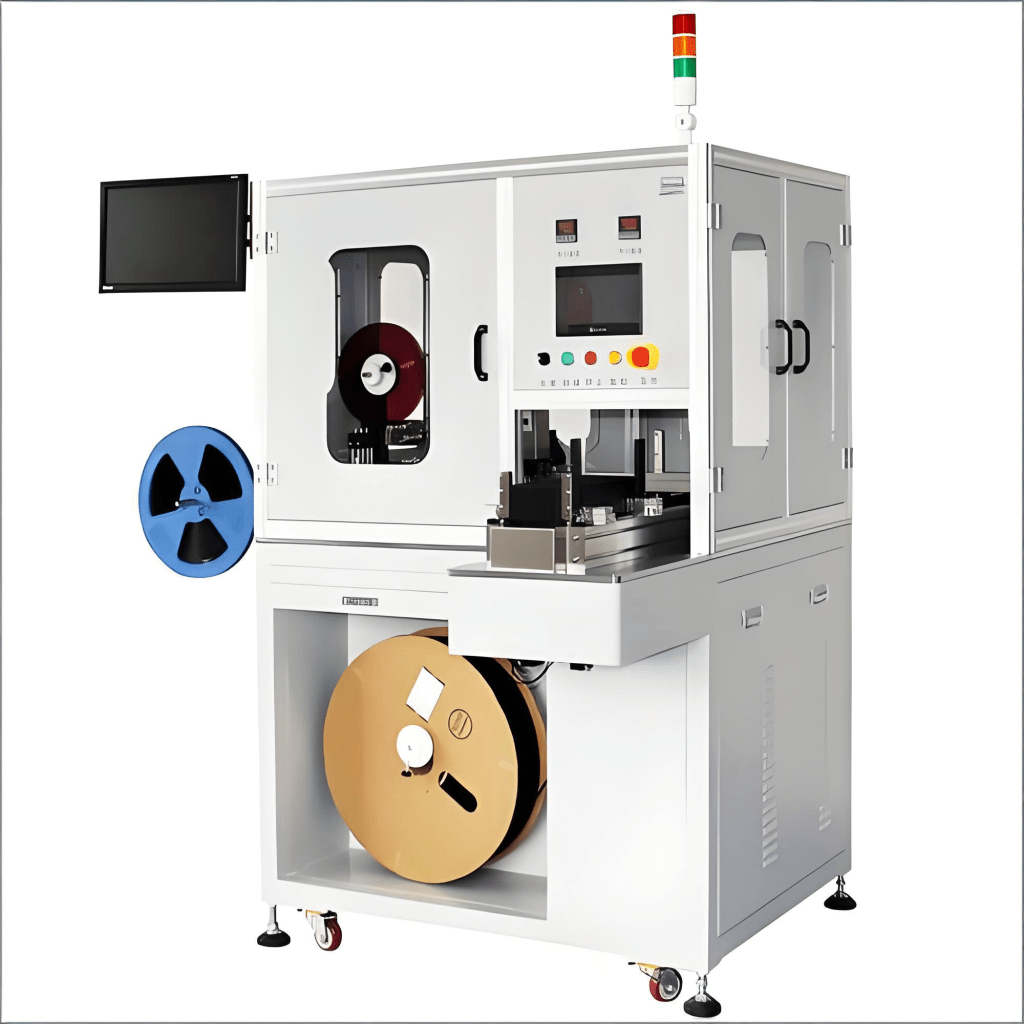

4.1 Taping & Tray Automation

Replaced manual taping with semi-automatic taping machines and added automatic tray packers on the secondary line to handle bulky parts. These devices reduced packaging errors and standardized reel/tray outputs for feeders. See our taping & tray guide for equipment selection and maintenance.

Taping Machines & Tray Packers — FAQ & Guide. :contentReference[oaicite:0]{index=0}

4.2 Inline Vision Inspection (AOI + AI)

Deployed AOI at post-placement and an AI-based anomaly detector at the taping/tray station to catch mis-oriented parts, missing parts, and damaged leads before they entered inventory. This prevented bad reels/trays from being fed into pick-and-place machines and cut downstream rework.

How to Optimize Taping Efficiency in Low-Volume PCB Production. :contentReference[oaicite:1]{index=1}

4.3 MES Integration & Traceability

Integrated taping/tray machines with MES to log reel/tray IDs, lot numbers, and inspection images — enabling rapid root-cause and quarantine of suspect inventory. Traceability lowered recall scope when a supplier deviation occurred.

SMT Line Setup Guide (Tag). :contentReference[oaicite:2]{index=2}

5. Implementation Steps & Timeline

- Week 0–2: Requirements gathering, KPI baseline measurement.

- Week 3–6: Procure semi-auto taping machines & tray packer; setup vision fixtures.

- Week 7–10: Pilot on single line; iterate AI model with real defect samples.

- Week 11–16: Rollout to second line + MES integration and operator training.

6. Results & Metrics (Post-implementation)

| Metric | Before | After | Change |

|---|---|---|---|

| Throughput (CPH) | 1,200 | 1,740 | +45% |

| Rework Rate | 4.8% | 1.8% | -62% |

| Labor hours/day on packaging | 6 | 2 | -67% |

| Cost-per-part | Base | Base × 0.82 | -18% |

7. Key Lessons Learned

Operational takeaways (click to expand)

- Pilot first: validate vision models and feeder workflows on a pilot line before scaling.

- Data matters: collect diverse defect samples for AI training to reduce false positives.

- Operator buy-in: involve shop-floor staff and train them on new workflows — it reduces resistance and errors.

- Maintenance plan: schedule preventive checks for taping/tray machines to avoid throughput regression. See our maintenance best practices. :contentReference[oaicite:3]{index=3}

8. Common Pitfalls & How We Avoided Them

- Ignoring feeder compatibility → we pre-checked feeder acceptance with vendor demos (reduced integration rework).

- Poorly labeled reels/trays → added barcode printing at packaging to ensure traceability.

- Underestimating tooling lead-time → ordered cavity tooling early and used temporary fixtures during pilot.

9. Vendor Selection Checklist

- On-site demo with your parts and pick-and-place. (Ask for live feed.)

- Spare parts & local support availability.

- MES/API integration capability & standard data export.

- Clear SLAs for uptime & MTTR.

10. Further Reading & Internal Resources

- How to Choose the Right Taping Machine for Your SMT Line. :contentReference[oaicite:4]{index=4}

- Taping Machines & Tray Packers — FAQ & Guide. :contentReference[oaicite:5]{index=5}

- SMT Automation Maintenance Best Practices (Tag). :contentReference[oaicite:6]{index=6}

- Tray Packing (Tag). :contentReference[oaicite:7]{index=7}

- SMT Line Setup Guide (Tag). :contentReference[oaicite:8]{index=8}

11. Conclusion

Targeted automation — focusing on packaging standardization, inline vision, and digital traceability — delivered measurable throughput and quality gains. For EMS providers, small pilots that validate vision models and feeder compatibility are the fastest path to low-risk, high-impact improvements. Want help running a pilot on your SMT line? Contact us

© SMT PACK LAB • For assistance with taping/tray automation, vision integration, or MES connectivity, contact us.

留下评论