Carrier tapes are specialized packaging materials used to hold SMD components in place during automated surface-mount technology (SMT) assembly. They ensure components are delivered accurately to pick-and-place machines, streamlining production and minimizing errors. Read More

These tapes are critical in modern electronics manufacturing, providing both protection and precise positioning for tiny components. They are typically made from durable plastic materials and include embossed pockets that securely hold each SMD part.

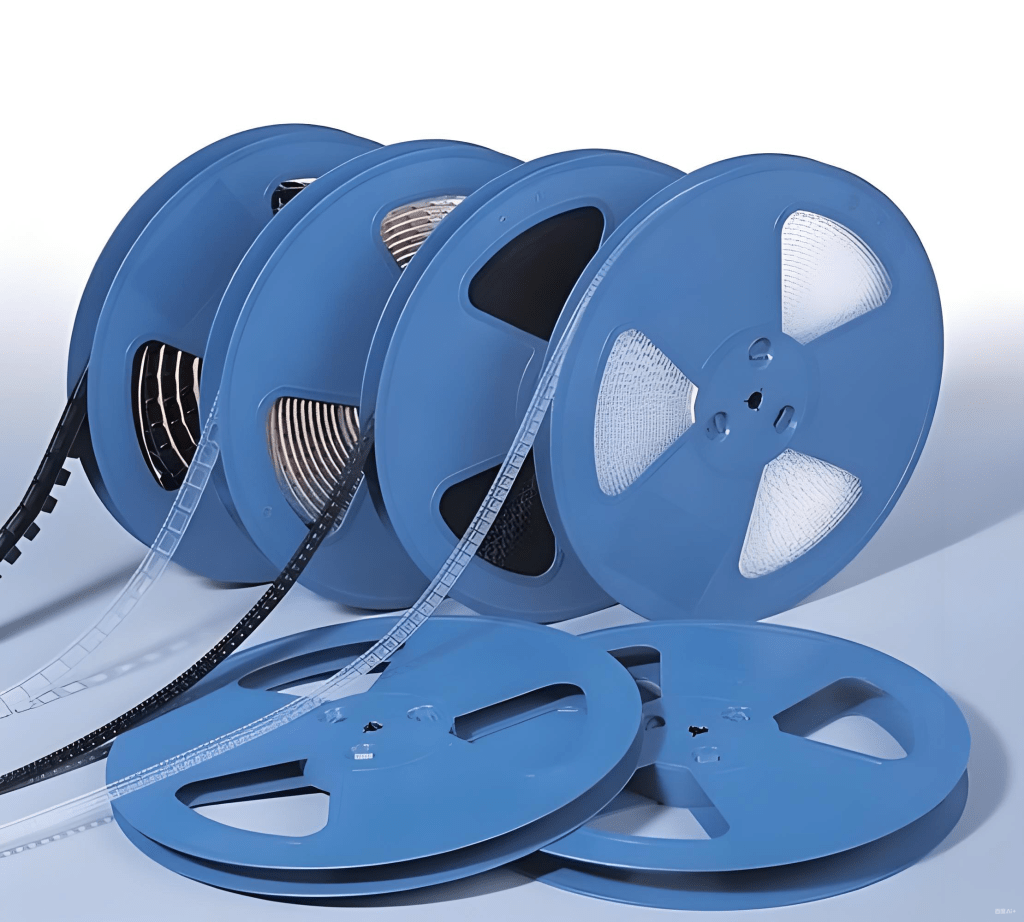

Types of Carrier Tapes

Carrier tapes can be broadly categorized into the following types:

- Plastic embossed tape: Most common, holds standard SMD components.

- Paper tape: Often used for larger or irregular components.

- Reel tape: Continuous reels for automated feeding.

Plastic Embossed Carrier Tape

Plastic embossed tapes have pockets molded specifically for each component type. They are ideal for automated assembly lines using SMT pick-and-place machines.

Paper and Reel Tapes

Paper-based tapes are used where electrostatic discharge (ESD) sensitivity is low. Reel tapes allow continuous feeding of components into the assembly line, reducing manual handling.

Usage in SMT Packaging

Carrier tapes are integrated with automated feeders that deliver components to pick-and-place machines. This ensures:

- Precise placement of components on PCBs.

- Minimized component damage.

- Efficient high-speed production.

Benefits of Carrier Tapes

Using carrier tapes in SMT packaging provides several advantages:

- Enhanced protection of delicate components.

- Reduced human handling and errors.

- Improved efficiency and throughput.

- Compatibility with automated SMT equipment from trusted providers like SMT PACK LAB.

Best Practices

To maximize the efficiency of carrier tapes:

- Store tapes in a clean, dry environment.

- Follow manufacturer guidelines for tape orientation.

- Check for component alignment before assembly.

- Use compatible feeders and pick-and-place machines.

Conclusion

Carrier tapes are essential for modern SMT assembly lines, ensuring components are delivered accurately and efficiently. By selecting the right type of tape and following best practices, manufacturers can enhance production quality and reliability.

留下评论