Understanding the key factors that affect taping precision can help reduce component damage, minimize downtime, and improve overall production efficiency.

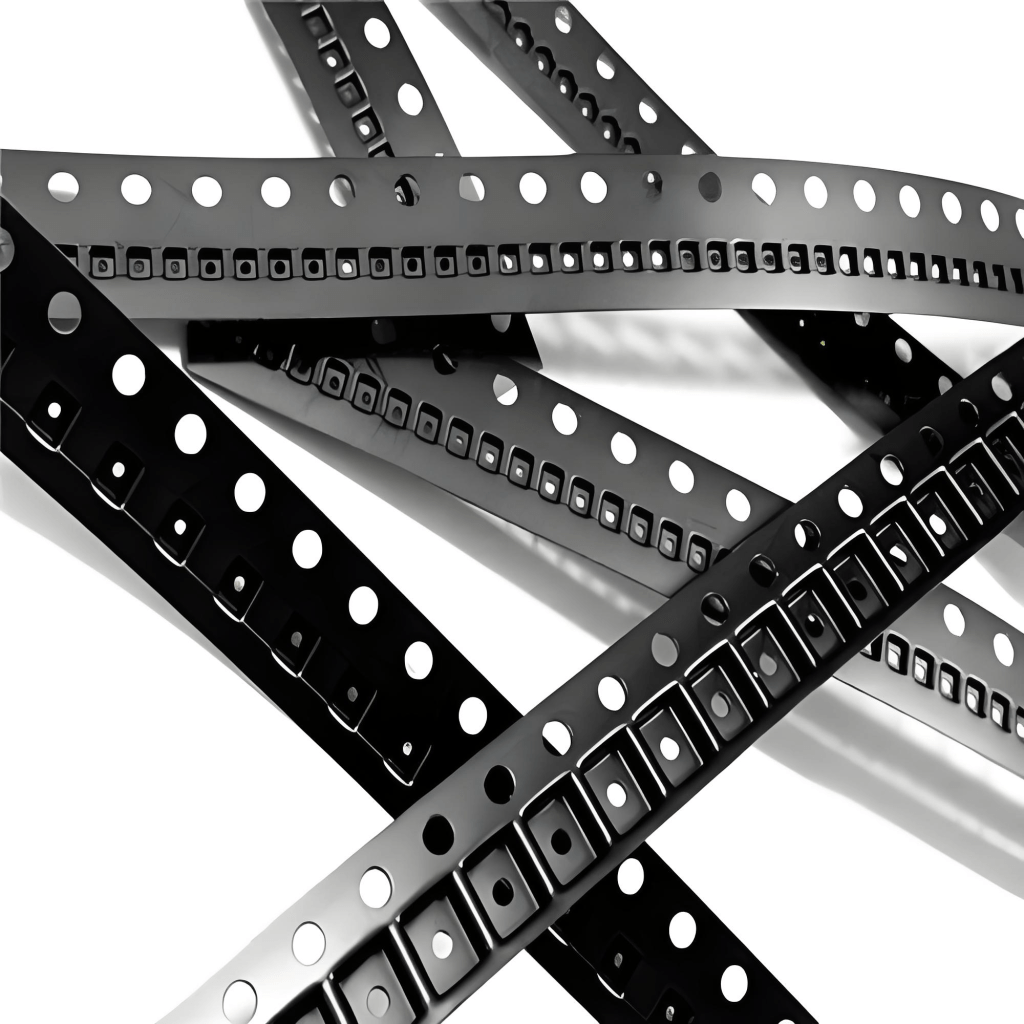

Carrier Tape Quality

The quality of carrier tape directly impacts the alignment and protection of SMD components:

- Use tapes that meet industry standards for thickness and durability.

- Ensure sprocket holes and tape dimensions are precise.

- Check for uniformity to prevent misfeeds or component tilting.

Cover Tape Selection

Cover tape choice affects component security and tape tension:

- Select the appropriate adhesive strength to hold components without damage.

- Consider peel strength to ensure smooth removal during assembly.

- Ensure compatibility with your taping machine.

Taping Machine Calibration

Proper machine calibration is critical for accuracy:

- Regularly adjust feed speed and tape tension.

- Ensure alignment between carrier and cover tape.

- Perform routine maintenance and inspection.

Component Size and Type

Different SMD components may require adjustments:

- Small or fragile components need precise alignment and handling.

- High pin-count components may require slower feed rates.

- Consider using tray packing for sensitive or irregular components.

Operator Skill and Training

Even automated systems depend on skilled operators:

- Train operators on machine operation and troubleshooting.

- Ensure correct loading of tapes and reels.

- Monitor and adjust parameters as needed during production.

Environmental Factors

Environmental conditions can affect taping accuracy:

- Maintain stable temperature and humidity in the production area.

- Protect against dust and static electricity (ESD).

- Ensure proper lighting for visual inspections.

Best Practices for Yield Improvement

- Regular maintenance and calibration of machines.

- Use high-quality carrier and cover tapes.

- Integrate pick-and-place machines for streamlined production.

- Document SOPs and train staff consistently.

- Continuously monitor yield data and optimize processes.

Conclusion

By focusing on carrier tape quality, cover tape selection, machine calibration, component handling, operator training, and environmental control, you can maximize taping accuracy and yield rate in SMT production. SMT PACK LAB provides solutions and guidance to help manufacturers achieve optimal results. Explore more SMT PACK LAB solutions.

留下评论