With components varying in size, weight, and shape, a one-size-fits-all setup can lead to errors. Understanding the calibration process is essential for smooth SMT production.

Why Calibration Matters

Calibration ensures that each component is correctly aligned and fed into the pick-and-place machine, reducing errors and increasing production yield.

Tools and Preparation

- Precision calipers or measurement tools

- High-quality carrier tapes for each component size

- Calibration software or machine manual

- Clean, static-free work environment

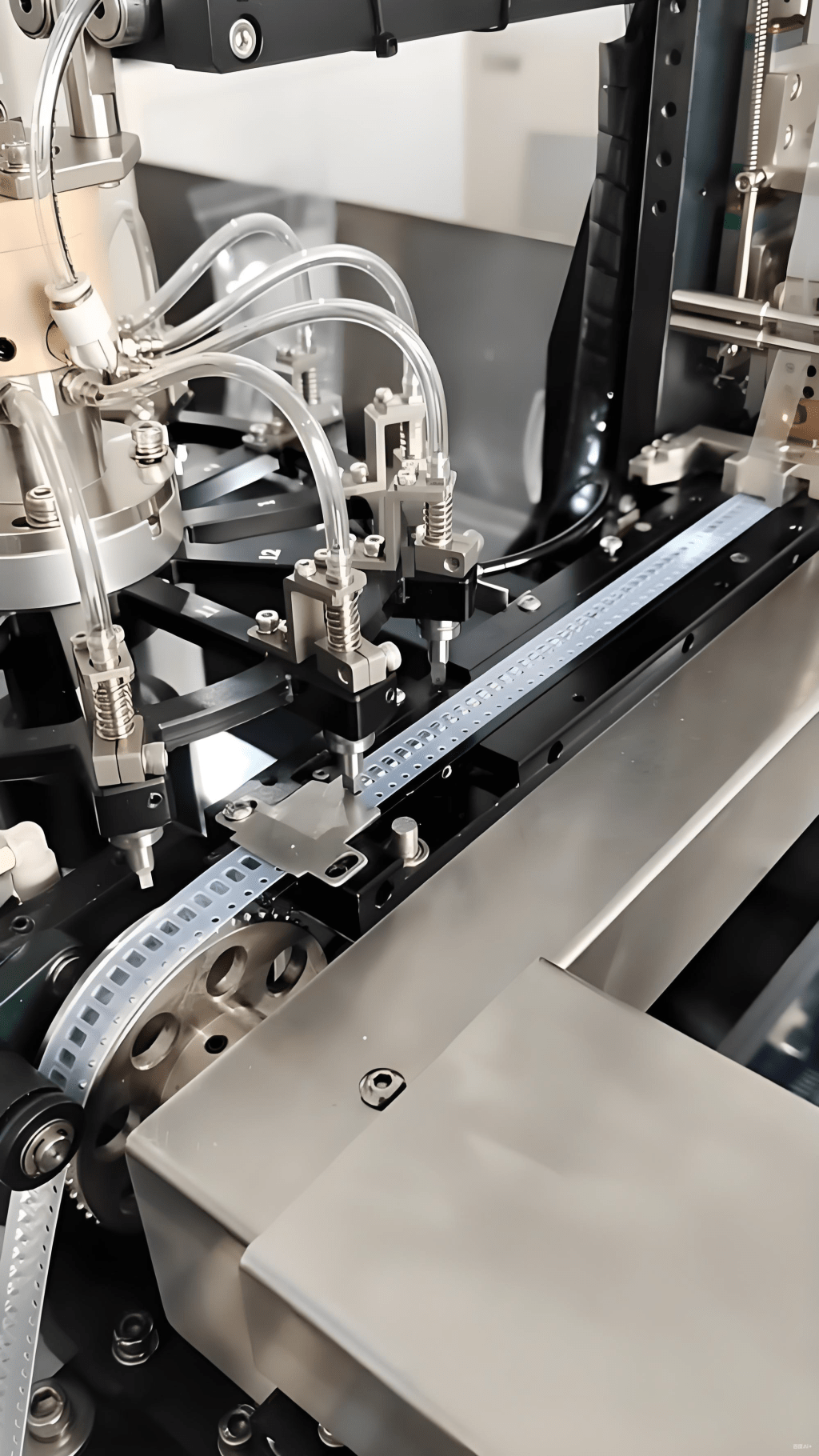

Step-by-Step Calibration Process

Follow these steps for accurate calibration:

- Measure Component Dimensions: Use calipers to record component width, height, and lead dimensions.

- Select Appropriate Carrier Tape: Choose tape pockets that match the component size. Learn more about carrier tapes.

- Adjust Tape Guides: Align the tape guides according to component width and tape pitch.

- Check Cover Tape Tension: Ensure proper adhesion and tension to prevent lifting or jamming.

- Run Test Feeds: Feed tape through the machine and inspect alignment at each stage.

- Fine-Tune Calibration: Adjust feed speed, pressure, and pick-and-place timing.

- Document Settings: Record calibration parameters for each component size for consistency.

Common Calibration Errors

- Incorrect tape guide width

- Improper cover tape tension

- Misaligned sprocket holes

- Neglecting component shape variations

- Inconsistent feed speed

Best Practices for Consistency

- Regularly maintain and clean the machine

- Train operators on calibration procedures

- Use standardized carrier and cover tapes

- Implement environmental controls for humidity and static

- Refer to SMT PACK LAB for expert support and solutions

Conclusion

Proper calibration of taping machines for different component sizes is essential to maintain high SMT production efficiency, reduce errors, and prevent component damage. Following the step-by-step process and best practices ensures consistent and reliable operations in electronics manufacturing.

留下评论