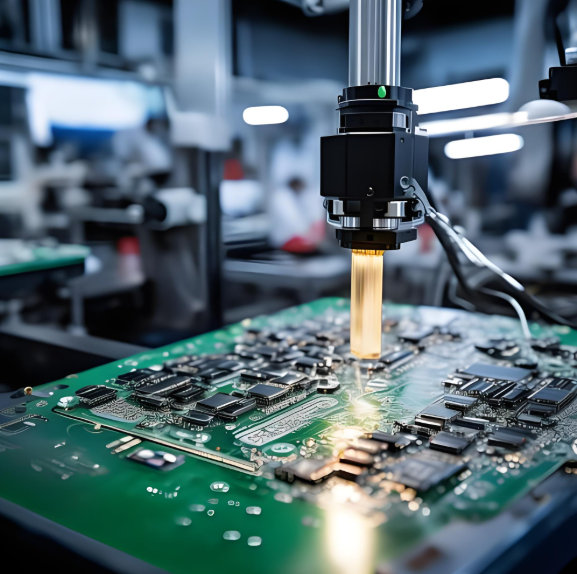

Introduction: The Critical Role of Solder Paste Printing

Solder paste printing is arguably the most critical step in the SMT assembly process. Studies show that over 60% of solder defects can be traced back to issues during the printing stage. Perfect solder paste deposition sets the foundation for successful component placement and reliable solder joints.

This comprehensive guide covers the essential best practices for solder paste printing, from material selection to process optimization. Whether you’re working with fine-pitch components, BGAs, or standard SMT devices, implementing these practices will significantly improve your first-pass yield and reduce rework costs.

Did You Know? The quality of solder paste printing directly impacts the success of subsequent reflow soldering and determines the long-term reliability of electronic assemblies.

Solder Paste Selection Guide

Choosing the right solder paste is fundamental to achieving consistent printing results. The selection should be based on your specific application requirements, component types, and process parameters.

Solder Alloy Considerations

Different solder alloys offer varying melting temperatures, mechanical properties, and compatibility with components:

| Alloy Type | Composition | Melting Point | Best Applications |

|---|---|---|---|

| SAC305 | 96.5% Sn, 3% Ag, 0.5% Cu | 217-220°C | General purpose, commercial electronics |

| Sn63Pb37 | 63% Sn, 37% Pb | 183°C | High-reliability, military (where permitted) |

| SAC387 | 95.5% Sn, 3.8% Ag, 0.7% Cu | 217-219°C | Fine-pitch, BGA applications |

| Sn96.5Ag3.5 | 96.5% Sn, 3.5% Ag | 221°C | High-temperature applications |

Flux Chemistry & Particle Size

The flux system and particle size distribution significantly impact printing performance:

- No-Clean Flux: Most common, leaves minimal residue, suitable for most applications

- Water-Soluble Flux: Higher activity, requires cleaning, for difficult-to-solder surfaces

- Rosin-Based Flux: Excellent wetting properties, typically requires cleaning

- Particle Size (Type 3-5): Finer powders for finer pitch components (0201, 01005, 0.4mm pitch)

Solder Paste Storage & Handling Guidelines

- Store solder paste at 0-10°C in sealed containers

- Allow 4-8 hours to reach room temperature before use

- Implement FIFO (First-In-First-Out) inventory management

- Record shelf life and use-by dates meticulously

- Never mix solder paste from different batches or manufacturers

- Keep containers sealed when not in use to prevent drying

Stencil Design Best Practices

Stencil design is the foundation of precise solder paste deposition. Optimal stencil parameters ensure the right volume of paste is transferred to each pad.

Aperture Design & Area Ratio

The area ratio (aperture area / aperture wall area) should typically exceed 0.66 for reliable paste release:

| Component Type | Recommended Stencil Thickness | Aperture Design | Area Ratio Target |

|---|---|---|---|

| 0402, 0603 components | 100-150μm (4-6 mil) | 1:1 with pad size | 0.70+ |

| 0201 components | 80-100μm (3-4 mil) | 1:1 or slight reduction | 0.75+ |

| 0.5mm pitch QFP | 100-120μm (4-5 mil) | 1:1 length, 90% width | 0.70+ |

| 0.4mm pitch & below | 80-100μm (3-4 mil) | 1:1 length, 85-90% width | 0.75+ |

| BGA/CSP | 100-150μm (4-6 mil) | Circular, 1:1 or slight reduction | 0.70+ |

Stencil Manufacturing & Finishes

Different stencil manufacturing methods and surface finishes impact paste release characteristics:

- Laser-Cut Stencils: Most common, excellent precision, smooth walls

- Electropolished Stencils: Improved paste release, reduced clogging

- Nano-Coated Stencils: Superior release properties, ideal for fine-pitch

- Electroformed Stencils: Highest precision, trapezoidal walls

Important: Always verify stencil design with a first-article inspection and conduct print trials before full production.

Printing Process Parameters

Optimizing printing parameters is essential for consistent, high-quality solder paste deposition.

Squeegee Selection & Parameters

Squeegee type, angle, pressure, and speed significantly impact print quality:

| Parameter | Recommended Range | Effect on Print Quality |

|---|---|---|

| Squeegee Pressure | 0.5-1.5 kg/cm | Too low: incomplete aperture filling Too high: stencil damage, paste smear |

| Print Speed | 20-80 mm/sec | Slower: better filling, lower productivity Faster: potential skipping, reduced volume |

| Separation Speed | 1-5 mm/sec | Slower: better paste release Faster: potential paste sticking to stencil |

| Squeegee Angle | 45-60 degrees | Affects paste roll and pressure distribution |

Print Gap & Cleaning Frequency

Proper setup of print gap and stencil cleaning protocols ensures consistent results:

- Print Gap: Maintain near-zero gap between stencil and PCB (0.0-0.2mm)

- 2D Alignment: Use vision systems for precise stencil-to-PCB alignment

- Stencil Cleaning: Clean after 5-15 prints depending on paste and complexity

- Paste Rolling: Maintain consistent paste roll ahead of squeegee

Environmental Control Parameters

Maintaining proper environmental conditions is crucial for consistent solder paste printing:

- Temperature: Maintain 20-25°C in printing area

- Humidity: Control at 40-60% RH to prevent paste drying or moisture absorption

- Cleanliness: Keep printing area free from dust and contaminants

- ESD Protection: Implement proper ESD controls for sensitive components

Equipment Setup & Maintenance

Proper printer setup and maintenance are essential for long-term printing consistency and reliability.

Printer Calibration & Verification

Regular calibration ensures printing equipment maintains precision:

- Vision System Calibration: Perform weekly or per shift change

- Squeegee Pressure Verification: Check and calibrate monthly

- Stencil Tension Measurement: Verify before each production run

- Board Support Alignment: Ensure proper support to prevent PCB flex

Preventive Maintenance Schedule

Implement a comprehensive preventive maintenance program:

| Maintenance Task | Frequency | Key Activities |

|---|---|---|

| Daily | Each shift | Clean printer, inspect squeegee blades, verify paste condition |

| Weekly | Once per week | Lubricate moving parts, clean vision system, verify calibration |

| Monthly | Once per month | Comprehensive inspection, replace worn parts, full calibration |

| Quarterly | Every 3 months | Professional service, software updates, performance verification |

Quality Control & Inspection

Robust inspection processes catch printing defects before they become assembly issues.

Solder Paste Inspection (SPI) Systems

Modern 3D SPI systems provide comprehensive measurement of paste deposition:

- Volume Measurement: Target ±30% of nominal volume for most applications

- Height Measurement: Critical for coplanarity and joint formation

- Area & Position: Ensure paste is within pad boundaries

- Bridging Detection: Identify potential shorts between pads

Acceptance Criteria & Process Control

Establish clear acceptance criteria and implement statistical process control:

| Parameter | Acceptance Criteria | Measurement Method |

|---|---|---|

| Paste Volume | 70-130% of nominal | 3D SPI |

| Paste Height | ±25% of stencil thickness | 3D SPI |

| Registration | ±50μm or 25% of pad width | 2D/3D Vision |

| Bridging | Zero tolerance | Visual/SPI |

Pro Tip: Implement real-time SPC (Statistical Process Control) to monitor printing process trends and detect deviations before they exceed control limits.

Troubleshooting Common Printing Issues

Quick identification and resolution of printing defects minimizes production downtime and rework.

Common Defects & Solutions

| Defect Type | Possible Causes | Corrective Actions |

|---|---|---|

| Insufficient Paste | Low pressure, fast speed, clogged apertures | Increase pressure, reduce speed, clean stencil |

| Paste Smearing | High pressure, large print gap, excessive paste | Reduce pressure, minimize gap, control paste volume |

| Poor Release | Dirty stencil, incorrect area ratio, dried paste | Clean stencil, redesign apertures, refresh paste |

| Bridging | Excessive paste, stencil damage, misalignment | Reduce paste volume, repair stencil, improve alignment |

| Tombstoning | Uneven paste volume, misalignment | Balance paste volume, improve registration |

Advanced Troubleshooting Techniques

For persistent printing issues, consider these advanced approaches:

- Printability Studies: Systematic evaluation of paste/stencil combinations

- Viscosity Testing: Regular measurement of paste viscosity

- Stencil Wear Analysis: Monitor stencil condition over time

- Design of Experiments (DOE): Systematic optimization of multiple parameters

- High-Speed Video Analysis: Study paste behavior during printing

Conclusion & Next Steps

Implementing these solder paste printing best practices will significantly improve your SMT assembly quality, yield, and reliability. Remember that printing is a system involving materials, equipment, processes, and people – optimization requires attention to all these elements.

The most successful implementations combine technical expertise with continuous improvement methodologies. Regular process audits, operator training, and data-driven decision making will help maintain printing excellence over the long term.

Ready to optimize your process? For specific applications or challenging components, our technical team can provide customized recommendations. Contact us through our Technical Support Center or explore our other resources on SMT assembly optimization and reflow soldering techniques.

留下评论