Meta Description:

Discover what Surface Mount Technology (SMT) is, how it revolutionized electronics manufacturing, and why it remains the foundation of modern PCB assembly. Learn about SMT processes, advantages, and equipment used in today’s high-efficiency production lines.

Introduction

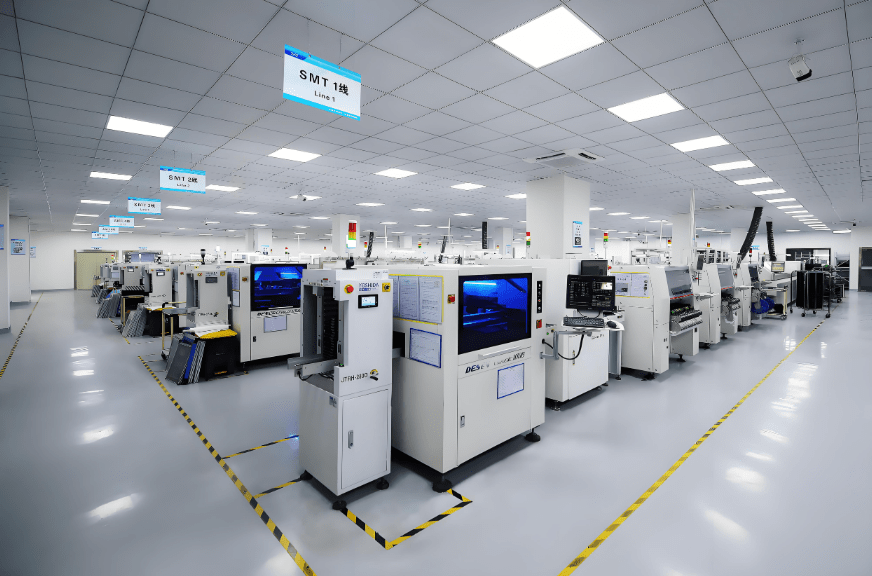

Surface Mount Technology (SMT) is the leading method used to assemble electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs).

It replaced the traditional through-hole technology (THT) and brought automation, miniaturization, and higher production efficiency to the electronics industry.

Today, nearly every modern device—from smartphones and computers to automotive sensors and medical equipment—relies on SMT assembly.

1. The Evolution of SMT

Before SMT, components were attached using leads inserted through holes in the PCB, known as through-hole assembly.

This process required manual labor and larger board sizes.

In the 1980s, the rise of surface-mounted devices (SMDs) transformed electronics manufacturing. SMT allowed components to be placed directly on the board’s surface using pick-and-place machines, drastically improving speed and precision.

2. How SMT Works

The SMT process typically involves the following steps:

Step 1: Solder Paste Printing

A stencil is used to apply solder paste onto the PCB pads, preparing the surface for component placement.

Step 2: Component Placement

Automated pick-and-place machines accurately position SMD components onto the soldered pads.

Step 3: Reflow Soldering

The board passes through a reflow oven, where heat melts the solder paste, bonding components permanently to the PCB.

Step 4: Inspection and Testing

Automated Optical Inspection (AOI), X-ray inspection, and functional testing ensure product reliability and quality.

3. Core Equipment Used in SMT

High-quality SMT lines use various automation systems, including:

- Taping Machines: Used to pack SMD components into carrier tapes for automated feeding.

- Tray Packing Systems: Arrange and store ICs and components for high-volume automated assembly.

- IC Programming Machines: Pre-program chips before they enter SMT production.

- Pick-and-Place Machines: Handle component placement with extreme accuracy.

- Reflow Ovens: Create strong solder joints under precise temperature control.

- Inspection Systems: Detect soldering or alignment defects with AI vision technology.

💡 At SMT PACK LAB, we specialize in advanced taping and tray packing solutions for SMD packaging lines, enabling manufacturers to achieve higher precision and production efficiency.

4. Advantages of SMT

SMT brought a revolution to the electronics industry, offering benefits such as:

- Higher Component Density – Allows for smaller, lighter products.

- Improved Electrical Performance – Shorter connections reduce resistance and inductance.

- Automation Ready – Supports full-scale automated production lines.

- Cost-Effective – Reduces manual labor and material waste.

- Consistency and Reliability – Precision machines ensure repeatable results.

5. SMT Applications

SMT is used across multiple industries, including:

- Consumer Electronics – Smartphones, tablets, wearables

- Automotive – Sensors, ECUs, lighting modules

- Medical Devices – Portable monitors, diagnostic equipment

- Telecommunications – Routers, signal amplifiers

- Industrial Equipment – Control boards, sensors, robotics

6. Future Trends in SMT

The SMT industry continues to evolve with the integration of AI, machine learning, and Industry 4.0.

Next-generation factories are embracing smart automation, data-driven process control, and real-time inspection systems to achieve zero-defect manufacturing.

SMT PACK LAB is at the forefront of this transformation—developing intelligent taping, tray packing, and inspection systems that redefine what’s possible in precision electronic packaging.

Conclusion

Surface Mount Technology (SMT) is not just a production method—it’s the backbone of modern electronics manufacturing.

From design to mass production, SMT ensures high-speed, high-accuracy, and high-reliability assembly that powers the digital world.

🚀 Looking to upgrade your SMT packaging line?

Contact SMT PACK LAB today to explore intelligent taping, tray packing, and inspection solutions tailored for your factory.

留下评论