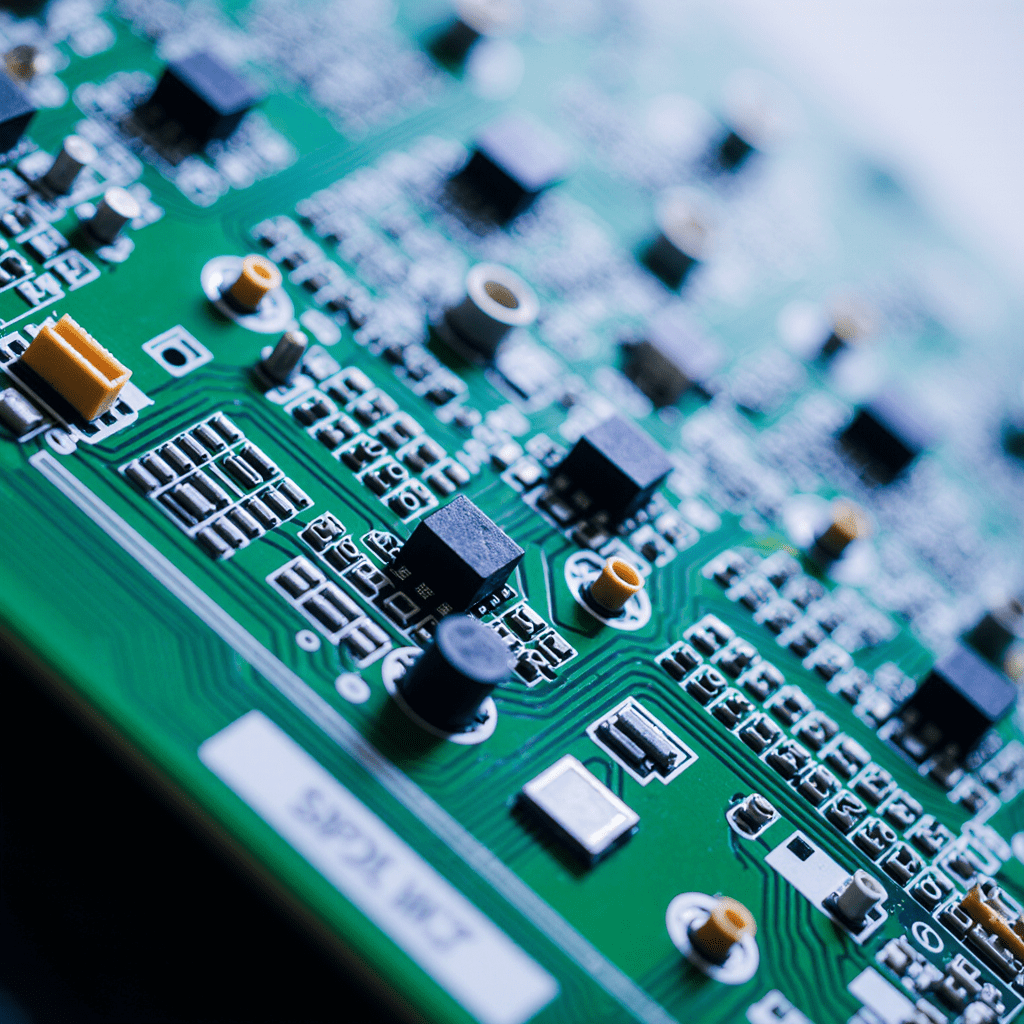

This guide explains what SMD and SMT are, how SMT assembly works, common component packages, the equipment and process steps involved, design rules, common defects and how to prevent them, and where to look next. It’s detailed but written for a beginner who wants practical, usable knowledge — ideal for engineers, purchasers, product managers, or anyone building electronics manufacturing capability.

- Quick definitions

SMD (Surface-Mount Device)

An electronic component designed to be mounted directly onto the surface of a printed circuit board (PCB). Examples: 0805 resistor, SOT-23 transistor, QFN, BGA.

SMT (Surface-Mount Technology)

The set of methods, processes and equipment used to assemble SMDs onto PCBs. SMT replaced the older through-hole assembly for most modern electronics because it enables higher density and automated production.

- Why SMT replaced through-hole (the benefits)

Smaller, denser boards — SMDs are compact and can be placed on both sides of the PCB.

Higher automation and throughput — pick-and-place machines and reflow ovens scale production.

Lower cost per unit at scale — less labor, faster cycles, less material overhead.

Better high-frequency performance — smaller parasitic inductance and capacitance.

Consistent quality — automated processes reduce human variability.

Tradeoffs / limitations: harder manual rework, thermal stress sensitivity for small parts, some mechanical strength issues for heavily stressed connectors (through-hole still used for connectors, large leads).

3. Typical SMD packages (common types)

Passive sizes (chips)

0201, 0402, 0603, 0805, 1206 — resistors, capacitors (numbers = imperial size; 0603 ≈ 1.6×0.8 mm).

Small active packages

SOT-23 — small transistors, MOSFETs.

SC70 / SOT-323 — very small discretes.

IC packages

SOIC / SOP — small outline ICs (through-hole counterpart: DIP).

TSSOP / TSOP — thinner small outline ICs.

QFP / LQFP — quad flat packages with gull-wing leads.

QFN / MLF — leadless flat packages with thermal pad.

BGA (Ball Grid Array) — solder balls under the package for high I/O density.

CSP / WLCSP — chip scale packages, very compact.

Packaging formats for supply to assembly

Tape & reel — common for automated feeders.

Cut tape — short runs.

Trays — for large/fragile ICs (BGAs, connectors).

Bulk — mainly manual assembly or low cost; not ideal for automated.

4. The standard SMT assembly process (step-by-step)

Below is a typical SMT line flow for a fully automated line:

PCB fabrication & preparation

PCB with solder mask, silk, and metal pads ready; fiducials added.

Solder paste printing (Stencil Printer)

A metal stencil (with apertures matching pads) deposits solder paste onto pads using a squeegee.

Key: paste volume, aperture design, and stencil thickness determine paste deposit.

Solder paste inspection (SPI) — optional but common

SPI checks paste volume and registration after printing.

Pick-and-Place

Machines pick components from tape/tray and place them onto paste-printed pads with high precision and speed.

Reflow soldering

Board passes through a reflow oven with a controlled thermal profile (preheat → soak → reflow/peak → cool). Solder paste melts, wets pads and component leads, then solidifies.

Post-reflow cleaning / flux removal — depending on paste/flux (no-clean flux often used to avoid cleaning).

Inspection

AOI (Automated Optical Inspection) for visible defects (bridges, missing parts).

X-ray / AXI for BGAs, hidden solder joints, and voids.

ICT (In-Circuit Test) or Flying Probe and Functional Test for electrical verification.

Rework / repair

Manual fix (hot-air, rework station) for defects.

Conformal coating, final assembly, packaging

For mixed technology boards (through-hole + SMD), often SMD assembly and reflow are done first, then through-hole components are wave-soldered or hand-soldered.

5.Reflow profile basics (conceptual)

A reflow profile has four stages:

Preheat — slowly raise temperature to activate flux and reduce thermal shock.

Soak — hold to equalize board temperature and stabilize.

Reflow (peak) — reach solder melting temperature; lead-free alloys often peak 245–260°C; SnPb peak ~183°C (note: exact temps depend on alloy & board).

Cooling — controlled cooling to solidify joints and avoid thermal shock.

Always use component and solder material datasheets to define the precise profile for your assembly.

- Essential SMT equipment (overview)

Stencil printer (solder paste printer) — accurate paste deposition.

Solder paste inspection (SPI) — measure paste volume/height.

Pick-and-place machines — from low-cost hobby to high-speed production.

Reflow oven — convection, infrared, or vapor-phase.

AOI (2D/3D) — automated optical inspection.

X-ray inspection (AXI) — for BGAs and hidden joints.

In-Circuit Tester (ICT) / Flying probe — electrical testing.

Conformal coating machines — protect assemblies.

Depanelizers, wave solder (if through-hole), rework stations.

- Design guidelines for SMT (PCB / DFM checklist)

Good PCB design for SMT improves yield and reduces cost. Key points:

Footprint & land patterns

Use IPC-7351 or manufacturer land pattern recommendations.

For QFN/BGA, pay close attention to thermal pad size and solder mask openings.

Paste mask design

For thermal pads, use multiple smaller apertures instead of one big aperture to reduce voiding and paste squeeze-out. Typical 60–80% paste coverage for thermal pad (specific depends on part).

Stencil

Stencil thickness & aperture shape control solder volume. Thicker stencil → more paste → stronger fillet but risk of bridges.

Fiducials & part orientation

Add at least two fiducials on the PCB for pick-and-place vision alignment.

Standardize part orientation to reduce feeder complexity.

Component spacing & access

Allow adequate spacing for placement accuracy and inspection.

Provide keep-out areas around test points and connectors.

Thermal & mechanical considerations

For large ICs, include thermal relief and heat-dissipating plane connection (vias-in-pad often via cap + fill).

Consider shock/strain for connectors; through-hole may be preferred for mechanical robustness.

Vias

Avoid vias in component pads unless you cap/fill them (BGA thermal pad via-in-pad must be filled/plated).

Use via tenting or solder mask to avoid solder wicking.

Design for Test (DFT)

Add test points accessible for ICT/flying probe.

Plan boundary scan or functional test connectors if ICT access is limited.

8. Common SMT defects, causes and fixes

| Defect | Symptom | Typical Cause | Remedy |

|---|

| Solder bridge | Short between pads | Too much paste, wrong stencil aperture, misalignment | Reduce paste, modify stencil, optimize placement accuracy |

| Tombstoning | One end of chip lifts | Uneven wetting, imbalanced pad sizes, temperature profile | Adjust pad design, improve thermal balance, tune reflow profile |

| Insufficient solder | Weak joints | Low paste volume, poor stencil | Increase paste aperture/volume or stencil thickness |

| Cold joint | Dull, grainy joint | Insufficient reflow / low temp | Adjust reflow profile to proper peak/soak |

| Component shift | Misplaced part after reflow | Excessive solder paste surface tension, vibration | Improve solder paste deposit, use proper board support |

| Voiding (BGA) | Internal voids under pad | Outgassing, improper thermal pad design | Use via fill, revise paste, optimize reflow profile |

| Solder balling | Small balls around pads | Flux outgassing, too high ramp rate | Adjust profile, clean flux, control humidity |

| BGA mispaste / opens | Open joints under BGA | Poor paste placement or reflow | Improve stencil, check BGA placement & X-ray |

- Inspection & testing strategies

AOI: fast first pass for visible defects (missing parts, polarity, bridges).

X-ray (AXI): required for BGAs, QFN bottom pads, hidden joints; detects voids and solder volume.

SPI: checks solder paste deposit before placement; prevents many downstream issues.

ICT / Flying Probe: electrical checks of nets, shorts, opens, component values; ICT needs in-circuit test points.

Functional Test: final test under operating conditions; often automated using test jigs.

A layered QC approach (SPI → Pick&Place verification → Reflow → AOI → AXI → ICT/Functional) yields high yields.

- Materials: solder paste, flux, and alloys

Solder paste = alloy powder + flux.

Alloys: lead-free is common (e.g., SAC305: Sn96.5/Ag3.0/Cu0.5). Leaded (Sn63Pb37) melts lower but less used due to RoHS.

Flux types: rosin, water-soluble, no-clean. Choice affects cleaning requirements and reliability.

Storage & handling: paste is temperature sensitive (store refrigerated; mix gently before use).

- DFM tips to improve yield (practical checklist)

Use IPC-recommended land patterns or vendor footprints.

Avoid too many different component sizes (simplify pick-and-place feeders).

Design for clear fiducials and consistent component orientation.

Minimize thermal imbalance between pads to prevent tombstoning.

Add test points and consider in-circuit / boundary-scan testing early.

Specify component tape & reel packaging for automated lines.

Plan for panelization to optimize depanelizer and board handling.

- When to choose SMT vs through-hole

Choose SMT for most components when you need density, speed, and automation.

Keep through-hole for high mechanical stress items (large connectors, ruggedized components), or when prototypes are hand-soldered frequently.

- Industry standards & references (what to learn next)

IPC-A-610 — Acceptability of Electronic Assemblies (visual acceptance criteria).

IPC-7351 — Land pattern standards.

IPC-J-STD-001 — Requirements for soldered electrical and electronic assemblies (materials & workmanship).

EIA standards (e.g., tape & reel formats like EIA-481).

(If you want, I can provide quick reference links or an annotated reading list.)

- Troubleshooting quick guide (common cases)

If boards have lots of bridges → check stencil apertures and paste volume; reduce paste or change aperture shape.

If many tombstones on 0402/0603 → check pad asymmetry and reflow profile; ensure balanced heat between pads.

If BGAs show opens or high voiding → check BGA alignment, stencil for ball paste deposition, consider via-fill and optimize reflow soak.

If inconsistent wetting → inspect solder paste shelf life, storage, and mixing; verify reflow temperatures.

- Practical next steps if you’re starting SMT production

Prototype with a contract manufacturer (EMS) — validate design before investing in equipment.

Create a DFM checklist early in the design stage (footprints, test points, panelization).

Start with no-clean solder paste and standard lead-free alloy unless product requires otherwise.

Invest in good stencil design & SPI — prevents many reflow issues.

Plan test strategy (ICT/flying probe vs boundary scan) based on production volume.

Run pilot batches and collect SPC (statistical process control) metrics before scaling.

- Glossary (short)

AOI — Automated Optical Inspection

AXI / X-ray — Automated X-ray Inspection

BGA — Ball Grid Array

DPMO — Defects per million opportunities

ICT — In-Circuit Test

IPC — Industry standard body for electronics (Institute for Printed Circuits)

PCB — Printed Circuit Board

SPI — Solder Paste Inspection

SMD — Surface-Mount Device

SMT — Surface-Mount Technology

留下评论